Cotton roll device

A technology for rolling cotton and cotton sheets, which is applied in the field of cotton sheet rolling devices, can solve the problems of inconvenient processing, poor rolling effect, and large rolling stick, and achieves the effects of good rolling effect and convenient subsequent production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

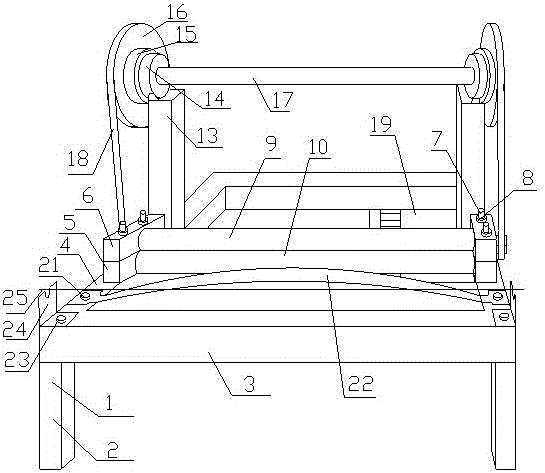

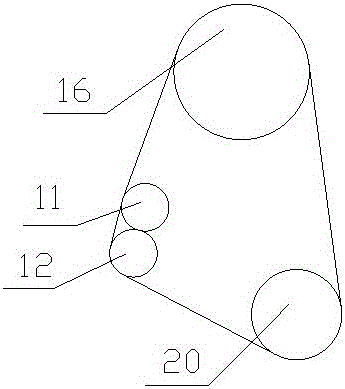

[0020] Such as Figure 1-Figure 2 It shows an embodiment of the cotton rolling device of the invention. The cotton rolling device includes a base 1, a rotating belt 18 and a motor 19. The motor 19 is located at the bottom of the base 1. The base 1 consists of 4 first support columns 2 and 2 beams. 3 and two longitudinal beams 4, the longitudinal beam 4 is fixed with a second support column 13, the second support column 13 is fixed with a fixed bearing 14, and the first rotating shaft 17 is passed between the fixed bearings 14, and the first rotating shaft The two ends of 17 are provided with the first rotating bearing 15, the first rotating disc 16 is connected to the periphery of the first rotating bearing 15, the second fixed block 5 is fixed on the longitudinal beam 4, and the first fixed block 6 is connected above the second fixed block 5 , the third rotating shaft 10 is arranged between the second fixed block 5, the third rotating disc 12 is arranged at both ends of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com