A long-span heavy-duty slideway beam for dragging

A slide girder, long-span technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as inability to meet construction requirements, and achieve the effects of high overall structural strength, strong compressive capacity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and non-limiting embodiment:

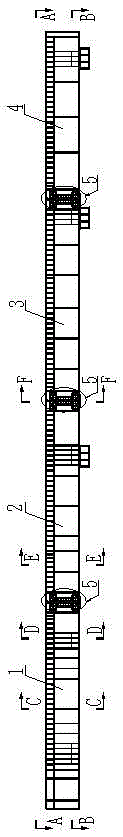

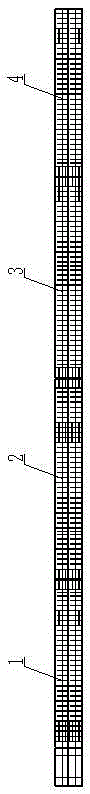

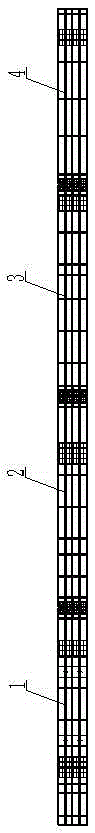

[0033] as attached figure 1 - attached Figure 7 , attached Figure 14 - attached Figure 16 As shown, a long-span heavy-duty slideway beam for dragging is assembled and connected longitudinally by a plurality of assembled segments. The slideway beam shown in this embodiment is composed of an assembled segment A1, an assembled segment B2, an assembled segment C3, and an assembled segment D4. Each assembled section includes two identical I-shaped steel beams 9 arranged side by side, and the upper surfaces of the two I-shaped steel beams 9 form a plane as a sliding surface of the slideway beam. Both sides of the web of each I-beam 9 in the assembled segment are provided with several reinforcing ribs, including: transverse reinforcing ribs 6, longitudinal reinforcing ribs 10, short reinforcing ribs 11, etc. The upper and lower parts of the adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com