Fixed-point control area grouting device and grouting process

A grouting device and grouting technology, applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve the problems of double liquid mixing in the hole, grout running out of the mold bag port, mold bag falling off, etc., and achieve wide application, Improve strength and impermeability, and ensure fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

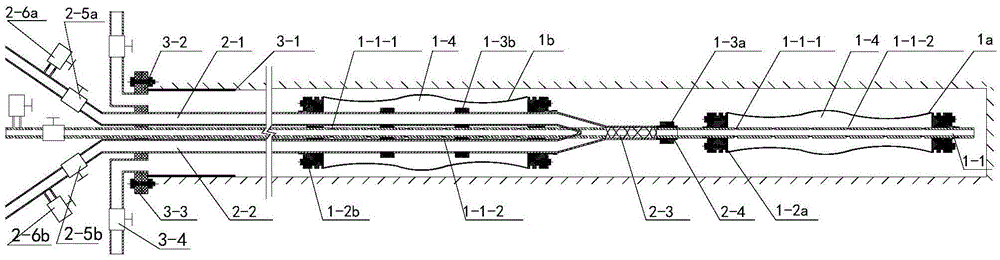

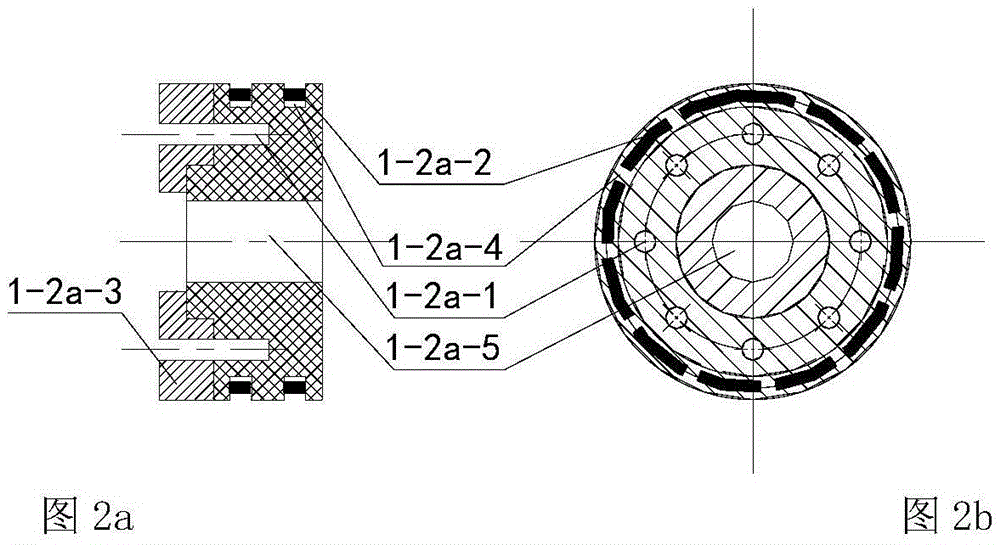

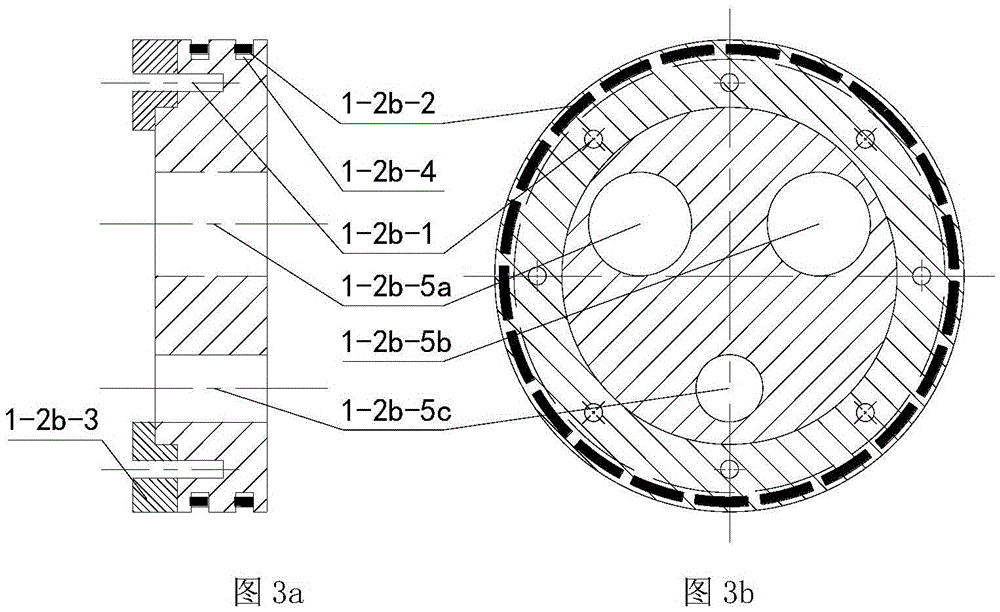

[0035] Such as figure 1 As shown, a fixed-point control area grouting device has an adaptive grouting barrier unit, a mixed double-liquid grouting unit in the hole, and an orifice fastening and sealing unit. The self-adaptive grout blocking unit is composed of a front blocking part 1a and a rear blocking part 1b, both of which are composed of a mold bag grouting pipe 1-1, a clamp, a lock, and a mold bag 1-4. The mixed double-fluid grouting unit in the hole is composed of a cement-based grouting pipe 2-1, a control liquid grouting pipe 2-2, a mixer 2-3, a short slurry outlet pipe 2-4, a grouting valve and a discharge valve. Pressure valve composition. The orifice fastening and sealing unit is composed of an orifice pipe 3-1, an orifice flange 3-2, a fastening flange 3-3 and a drain control valve 3-4.

[0036] Such as figure 1 As shown, the mold bag g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com