Energy-saving atmosphere box-type furnace

An atmosphere box and furnace body technology, which is applied in the field of heat treatment equipment, can solve the problems of high specific heat capacity of thermal insulation bricks, dead ends of powder heat treatment, and effectiveness, and achieve the effect of low specific heat capacity and uniform heat distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

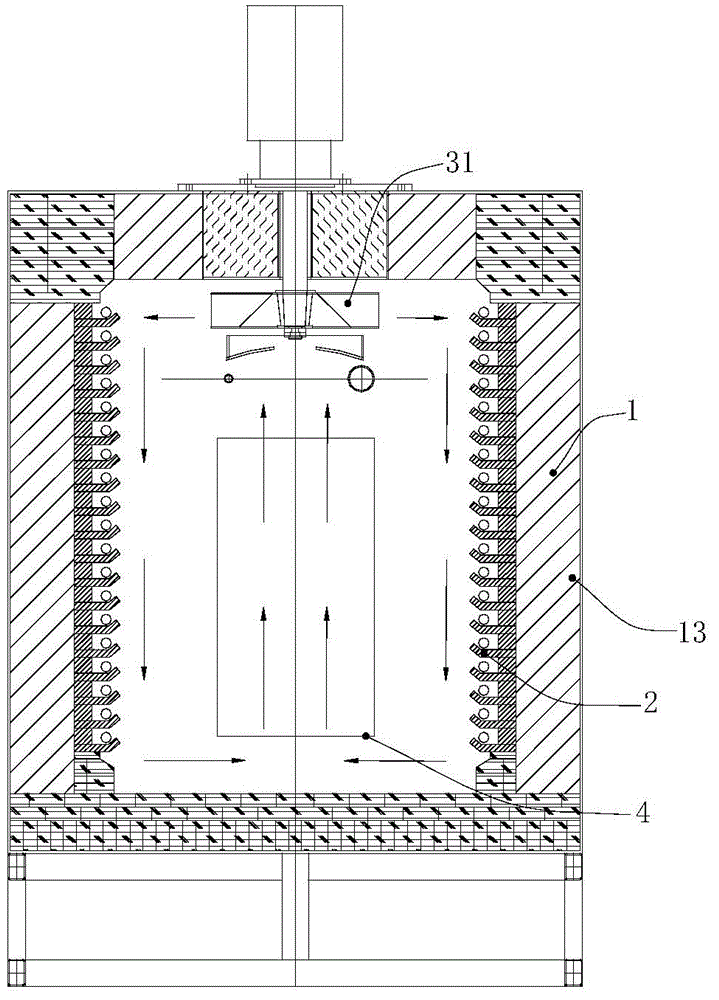

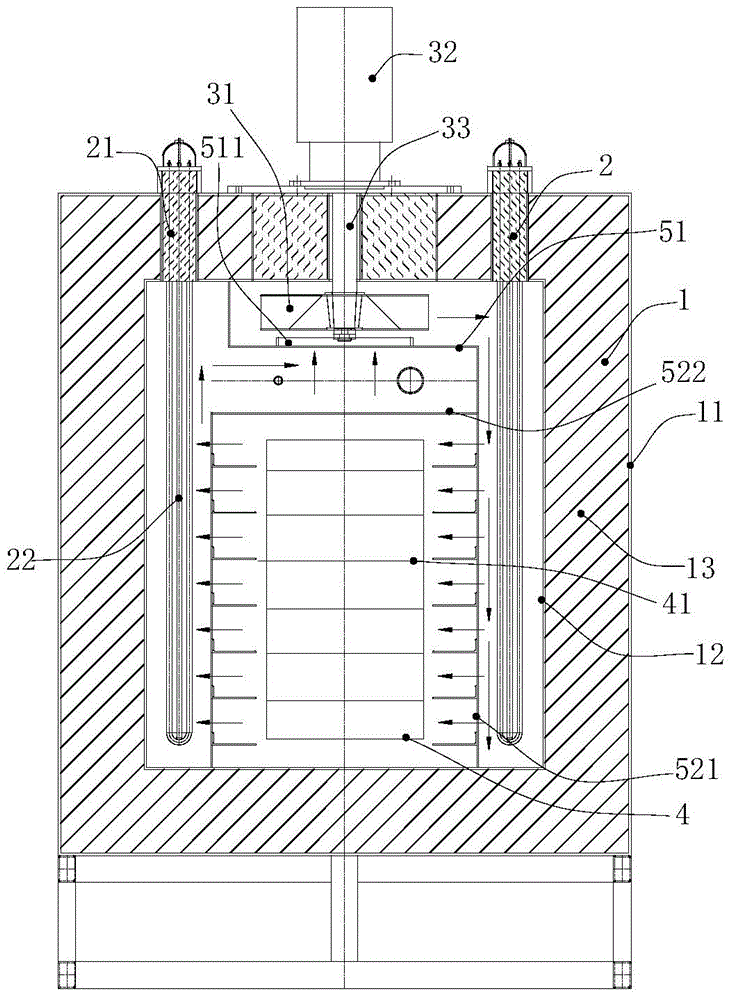

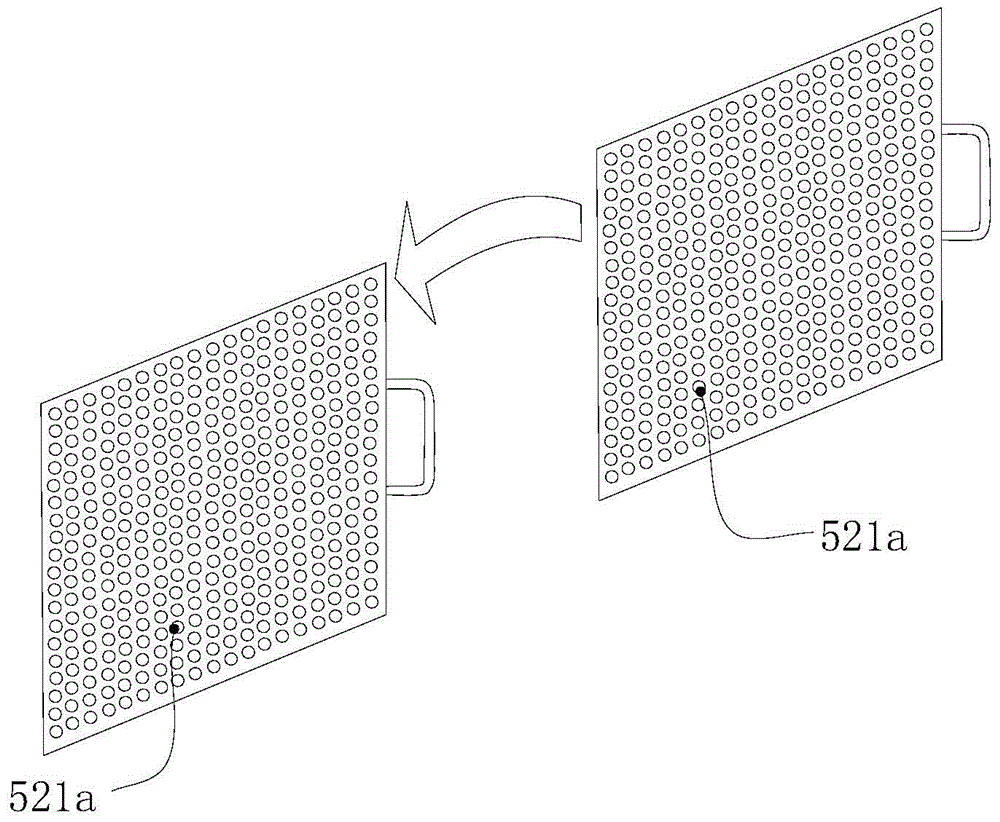

[0020] Such as Figure 2~Figure 5 The shown energy-saving atmosphere box furnace includes a holding furnace body 1 into which a protective gas is passed, a heating device for heating the protective gas, and a driving device for driving the flow of the protective gas, and for placing A powder furnace inner bladder 4, and a return air channel for guiding the protective gas.

[0021] The holding furnace body 1 includes an outer furnace wall 11 and an inner furnace wall 12, and a holding furnace lining 13 made of ceramic aluminum silicate. The holding furnace lining 13 is filled between the outer furnace wall 11 and the inner furnace wall 12; the ceramic aluminum silicate has It has the characteristics of fire resistance, heat preservation and heat insulation, and its specific heat capacity is lower than that of traditional insulation bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com