Box-sharing type ring network cabinet

A technology of ring network cabinet and common box type, which is applied in the direction of substation/switchgear board/panel/desk, switchgear, electrical components, etc., which can solve the cumbersome design of the shell, adjust the degree of gear meshing and the corresponding opening distance. , low production efficiency and other issues, to achieve the effect of simple and convenient assembly process and easy meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

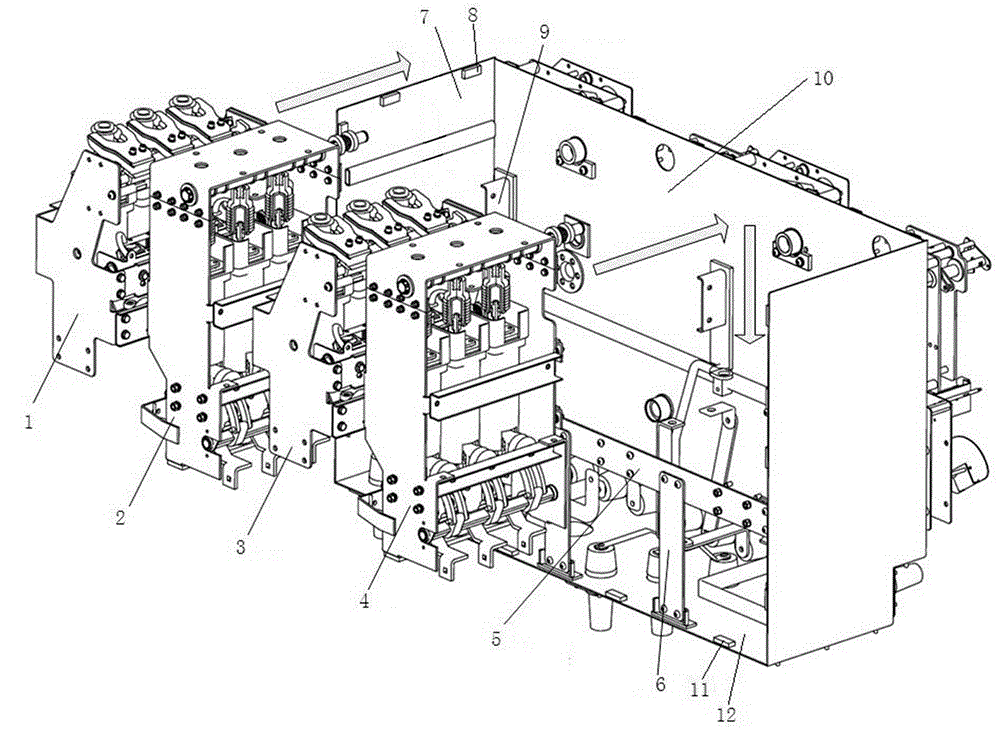

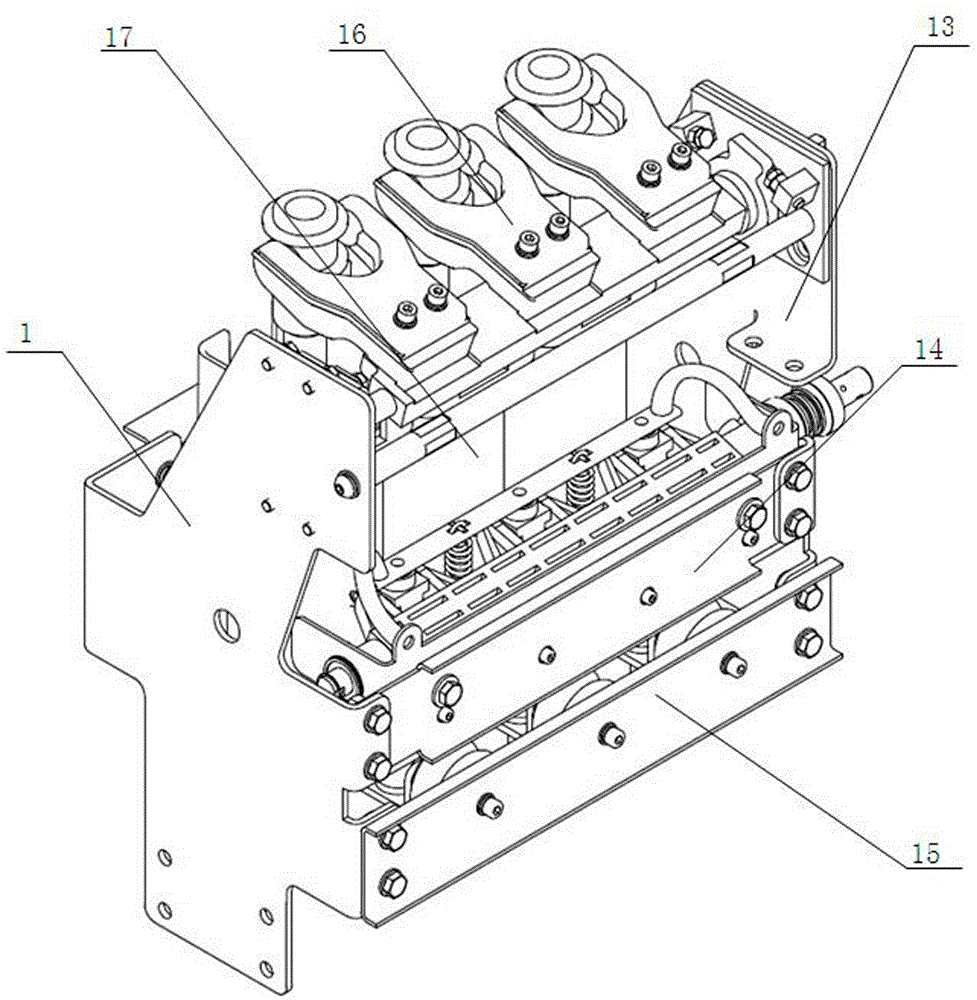

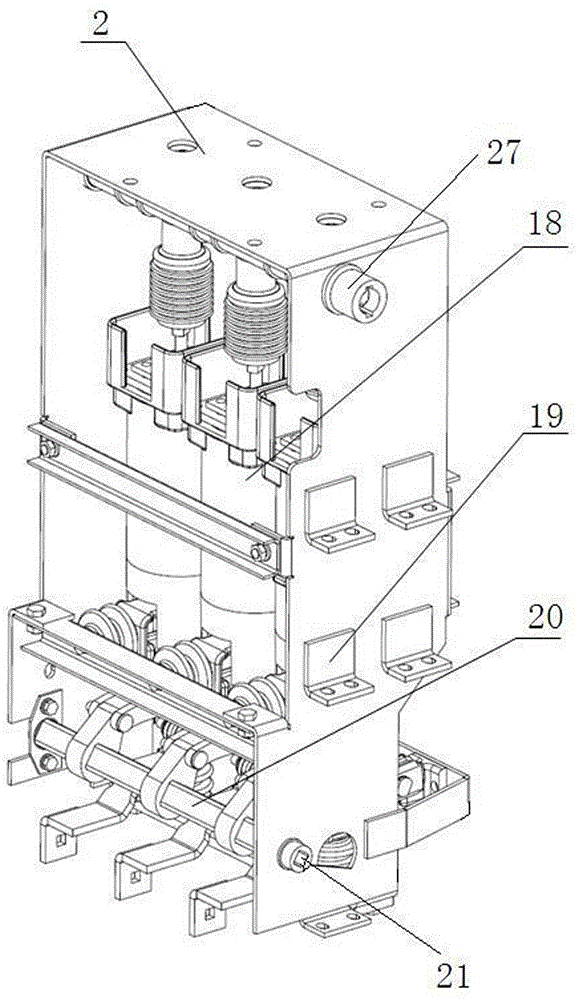

[0018] Examples of common box ring network cabinets Figure 1~4 Shown: includes a shell, the shell includes a top plate, a bottom plate 12 placed between the top plate (not shown in the figure), a front side plate 10 between the bottom plate, a rear side plate (not shown in the figure), a left side plate 7 and On the right side panel, the first mounting frame 1, the second mounting frame 2 and the third mounting frame 3 are arranged at intervals along the left and right directions in the shell, after the first, second, and third mounting frames are pushed into place from back to front Each installation frame is fixed on the housing through a fixed structure, the second installation frame 2 is provided with a circuit breaker and a three-position switch arranged up and down, and the first installation frame 1 is provided with a load switch and a grounding switch arranged up and down, The third installation frame 3 is provided with a load switch fuse combination, which has a load...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap