A high-voltage circuit breaker with integrated buffer and counterweight

A high-voltage circuit breaker and buffer technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problem that the buffer is not in the buffer energy absorption state, the equivalent mass of the main drive arm is small, and the problems such as the buffer performance of the gate, to achieve the effect of simple structure, simple assembly and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

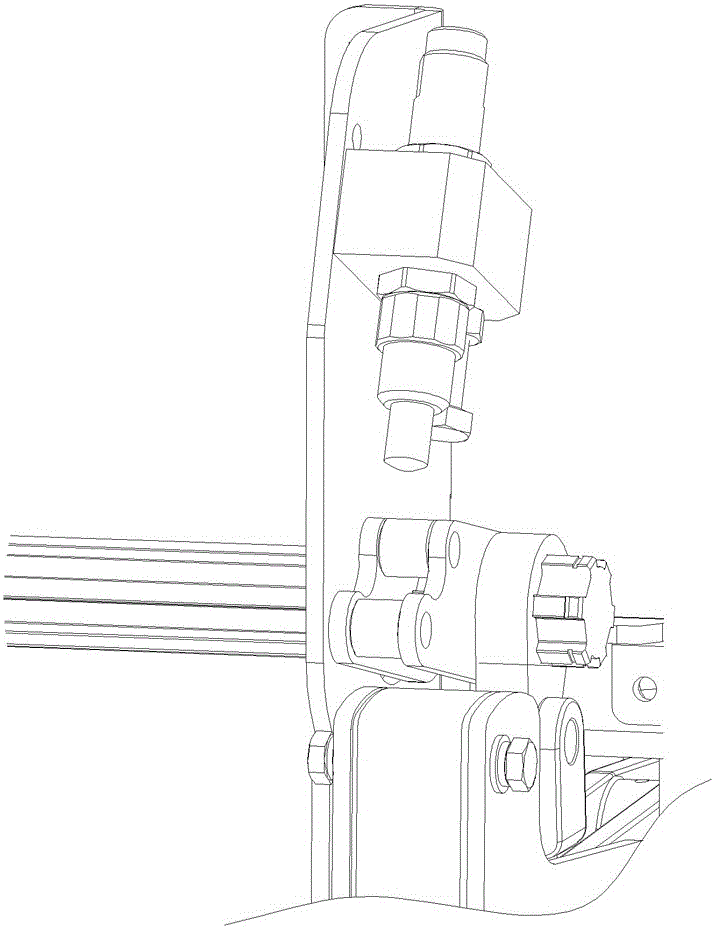

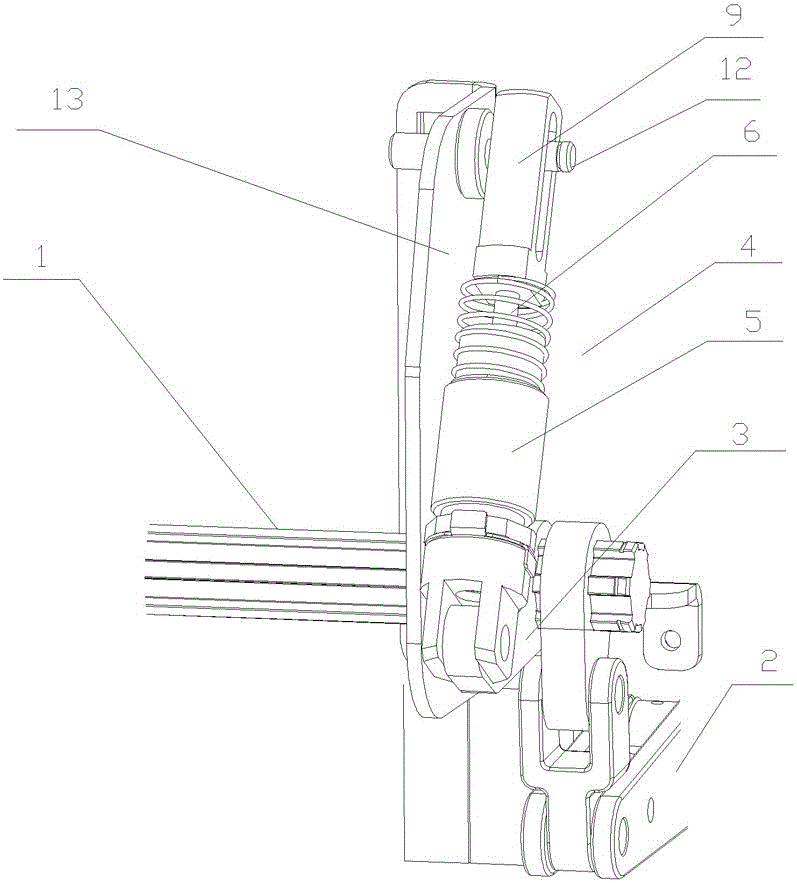

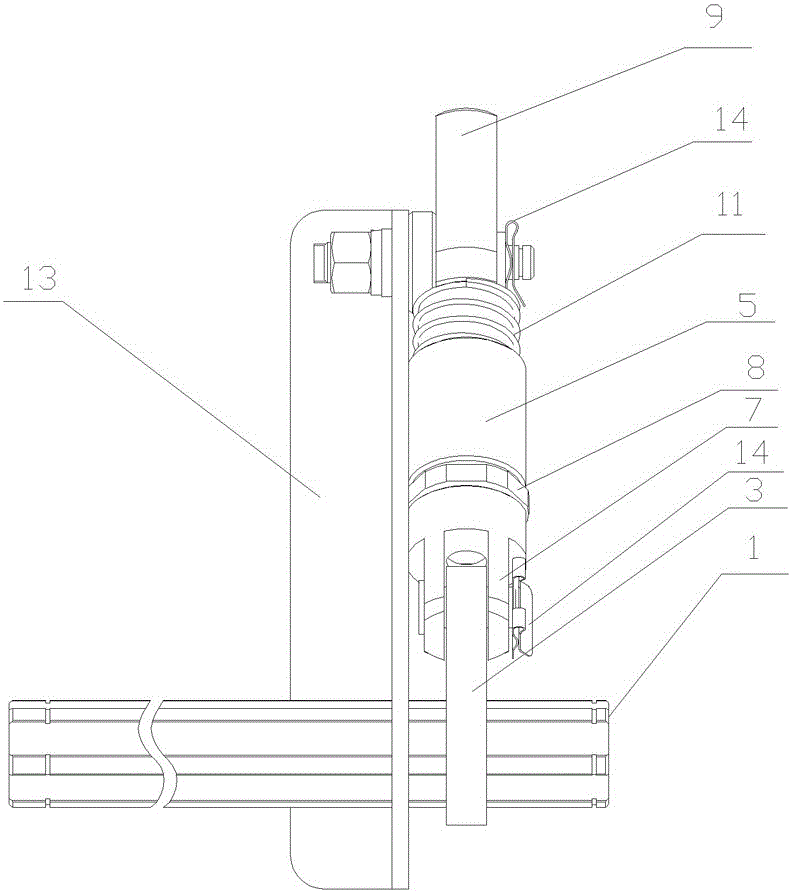

[0022] The utility model is described in further detail below in conjunction with accompanying drawing and specific embodiment.

[0023] like Figure 2-4 As shown, a high-voltage circuit breaker with integrated buffer and counterweight includes a housing, a main circuit arranged in the housing, an arc extinguishing mechanism, and an operating mechanism. The main circuit includes static contacts and moving contacts, and the operating structure Including the main shaft 1, the main shaft 1 drives the movable contact to reciprocate through the transmission assembly to perform the opening and closing action, and the transmission assembly includes the main transmission crank arm 2 connected to the main shaft 1. The outer surface of the main shaft 1 is provided with splines, and the crank arm 3 is provided with matching spline through holes, and the main shaft is splined to connect the crank arms. The crank arm 3 is connected to a buffer 4, and the buffer 4 includes a buffer cylinde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap