Footwear outsole member

A technology of components and components, applied in soles, insoles, footwear, etc., can solve problems such as liquid leakage and achieve the effect of mitigating impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

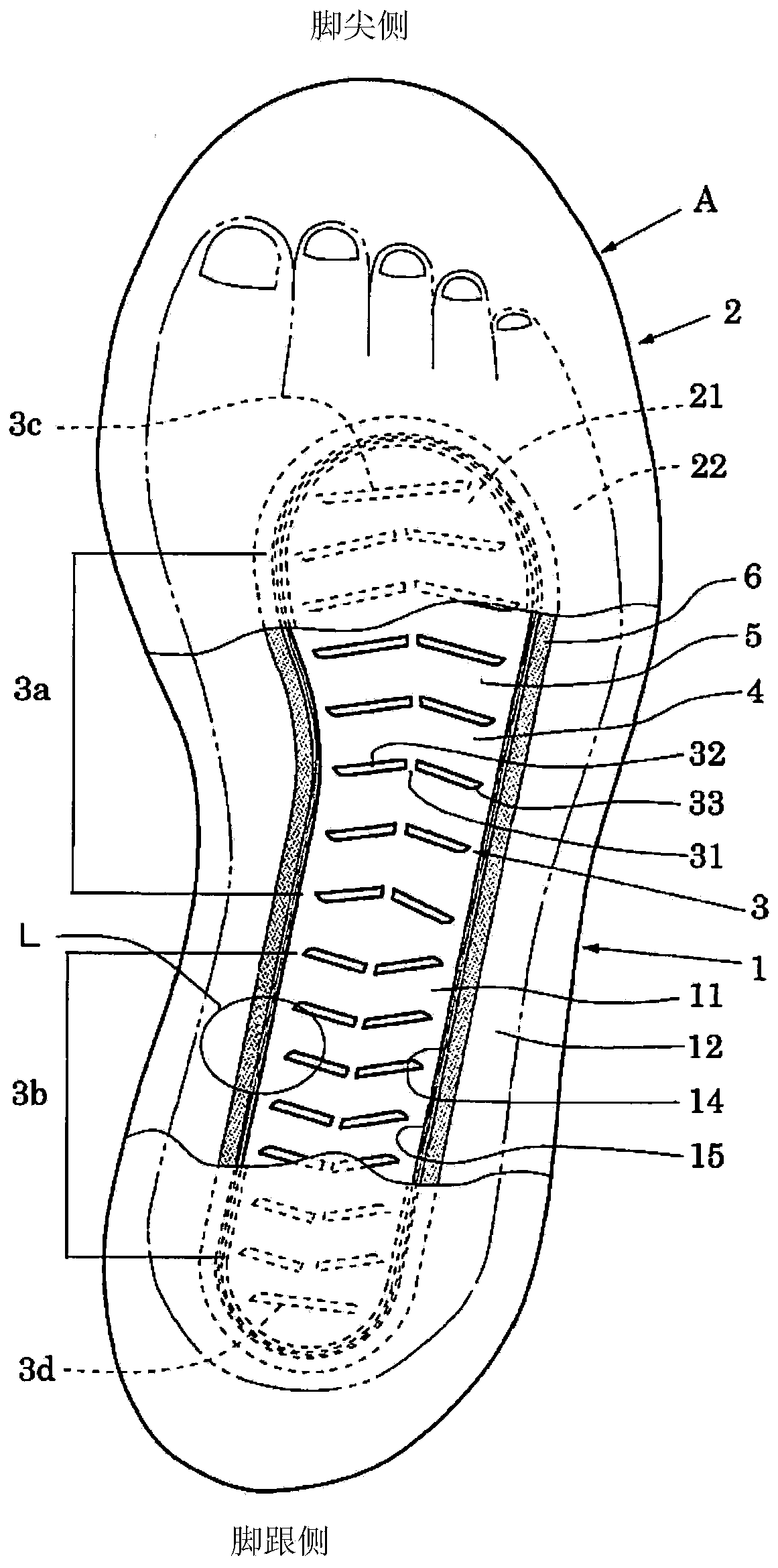

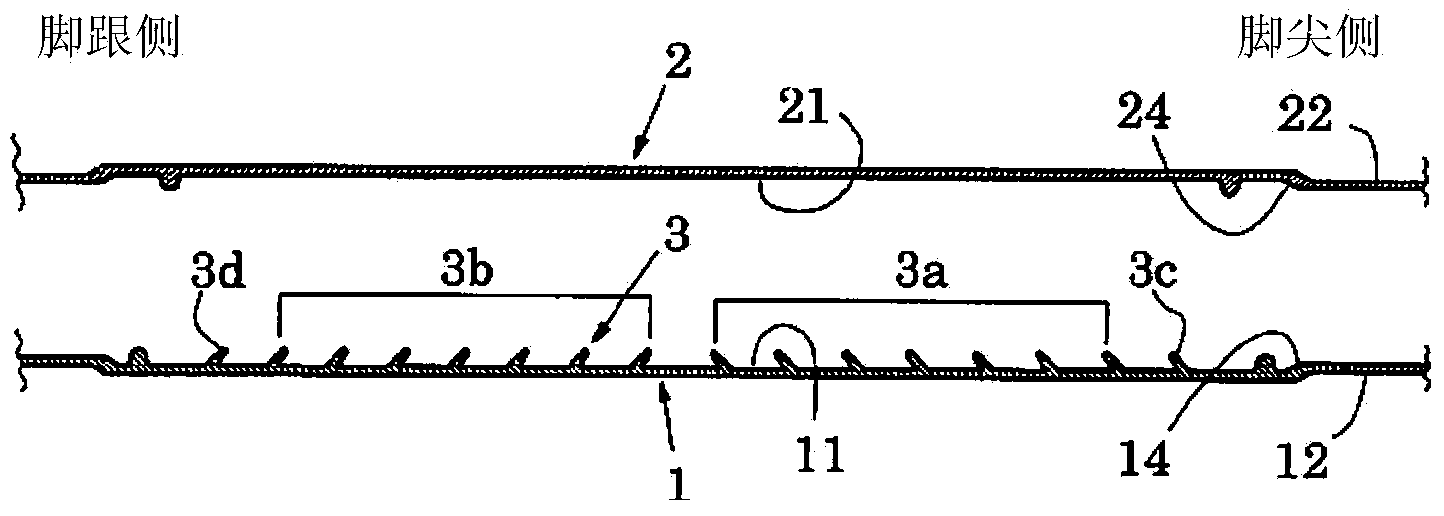

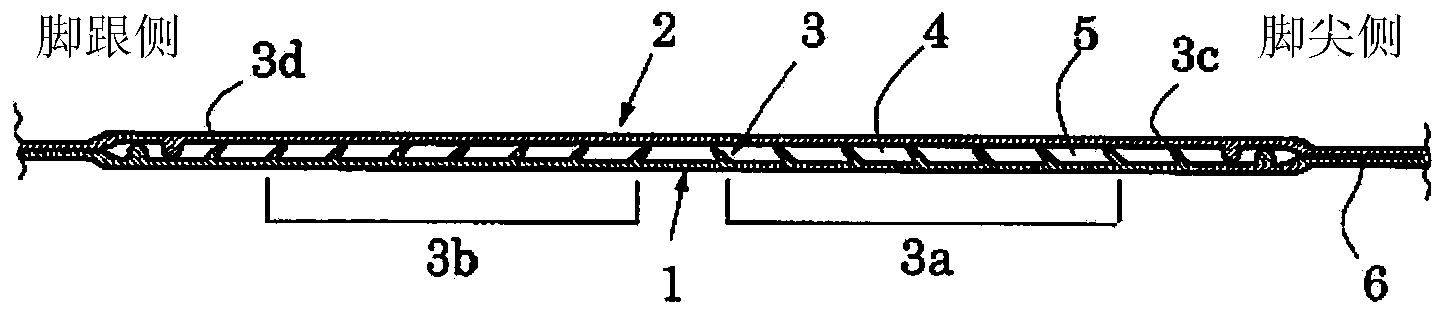

[0084] refer to Figure 1 to Figure 7 , taking the midsole of a shoe as an example to illustrate the bottom member of the shoe of the present invention. Such as figure 1 As shown, the midsole A of the present invention includes a bottom plate 1 , a cover 2 , a plurality of blades 3 and a liquid 4 .

[0085] The bottom plate 1 has a first region 11 having a shape corresponding to the sole of a foot, and a first horizontal flange portion 12 surrounding the entire circumference of the first region. Furthermore, the cover material 2 has a second region 21 facing the first region 11 provided on the bottom plate 1 and a second horizontal flange portion 22 facing the first horizontal flange portion 12 . Additionally, as from figure 1 As can be clearly seen, the first region 11 of the soleplate 1 is formed to have a length from the heel to the front of the root of the toe, and a width in the lateral direction when the sole of the foot is on the ground.

[0086] In addition, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com