Screw compressors

A screw compressor, compression chamber technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as heightening and shortening the life of structural components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

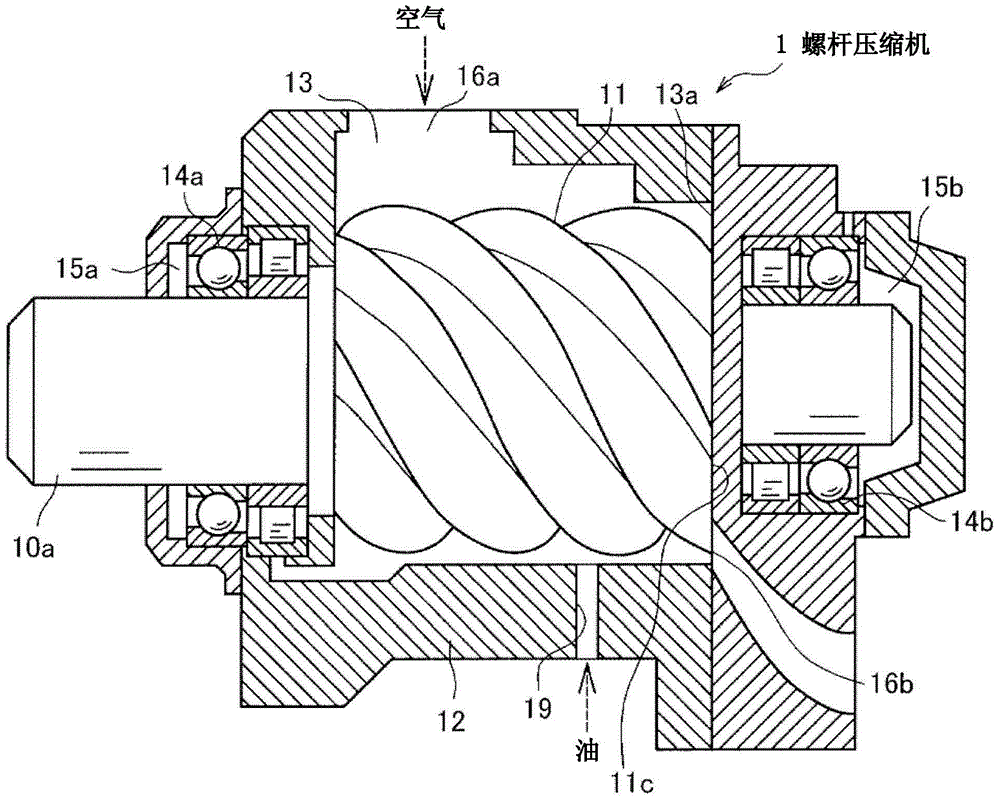

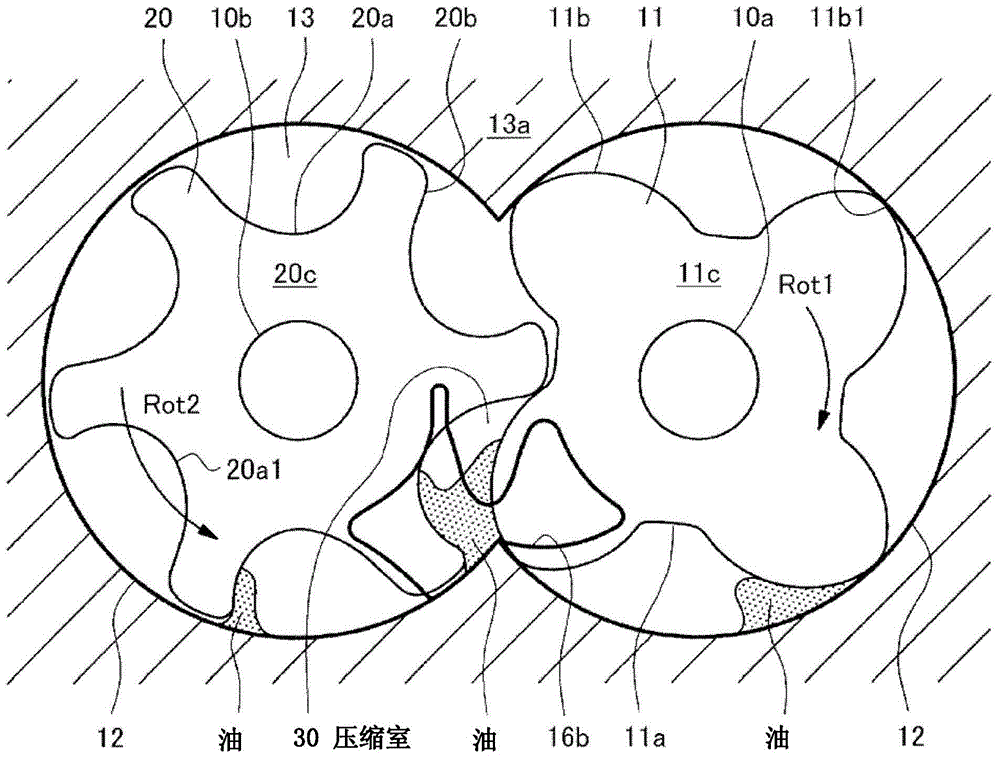

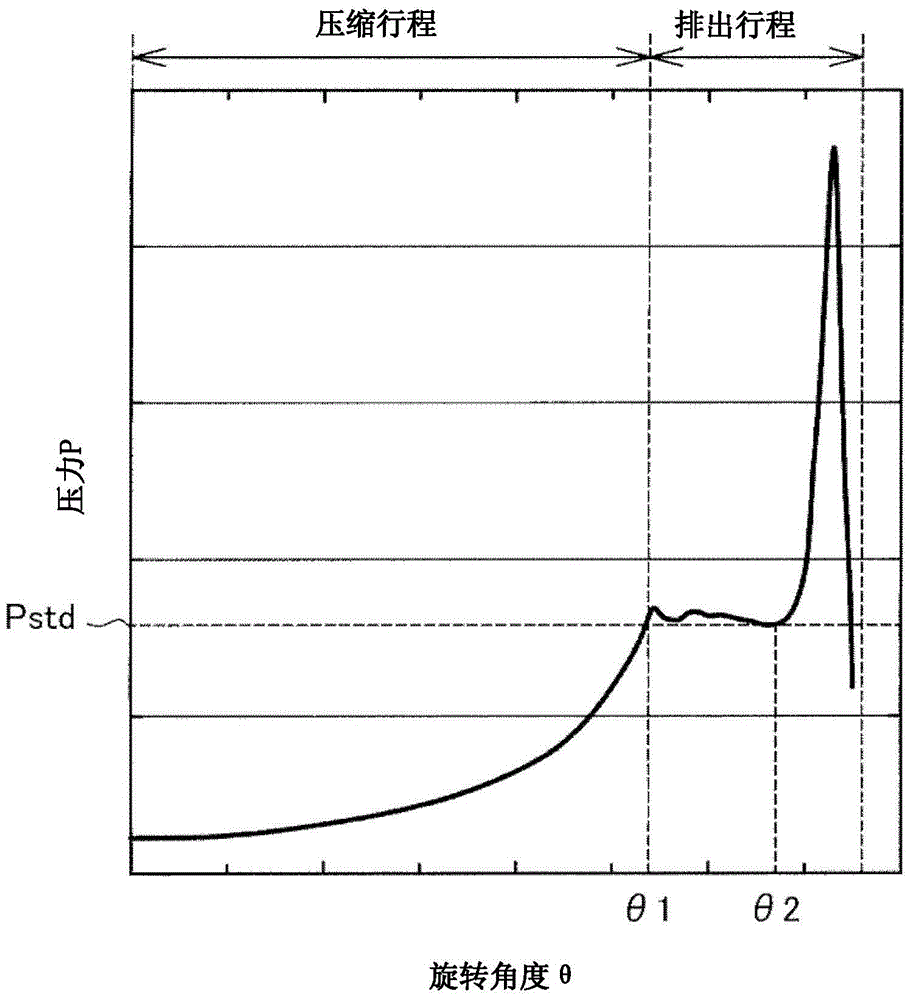

[0025] figure 1 It is a sectional view showing the structure of the screw compressor according to Embodiment 1 of the present invention. also, figure 2 It is the figure which observed the 1st rotor and the 2nd rotor of the conventional shape from the discharge end surface side, image 3 is a graph showing the pressure change in the compression chamber. also, Figure 4 (a) is a figure which shows the oil storage part formed in the tooth part of a 1st rotor, (b) is a perspective view of an oil storage part. also, Figure 5 It is a figure which shows the state which the compression chamber disappeared.

[0026] Such as figure 1 , figure 2 As shown, the screw compressor 1 of Embodiment 1 compresses a working fluid by using the first rotor 11 (male rotor) and the second rotor 20 (female rotor) rotating in mesh with each other. and if figure 2 As shown, the rotation direction Rot1 of the first rotor 11 is opposite to the rotation direction Rot2 of the second rotor 20 . ...

Embodiment 2

[0065] Figure 8 (a) is a figure which shows the oil storage part of Example 2, (b) is a perspective view of an oil storage part.

[0066] In addition, the screw compressor equipped with the first rotor and the second rotor of Embodiment 2 is the same as figure 1 , figure 2 The screw compressor 1 of the illustrated embodiment 1 has the same structure. Therefore, the same structural elements as those of the screw compressor 1 of Embodiment 1 are attached with figure 1 , figure 2 The same symbols are used and detailed explanations are omitted.

[0067] Such as Figure 8 As shown in (a) and (b), the tooth portion 20b of the second rotor 20 in Embodiment 2 is provided with a second concave portion (second oil storage portion 23) instead of the first oil storage portion formed on the first rotor 11. 22 (see Figure 4 (a)).

[0068] The second oil storage portion 23 formed on the second rotor 20 of the second embodiment is formed by orienting the axial end surface 20c of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com