Fuel system having flow-disruption reducer

A fuel system and reducer technology, applied in the direction of charging system, fuel injection pump, fuel injection device, etc., can solve the problem of damage to the filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

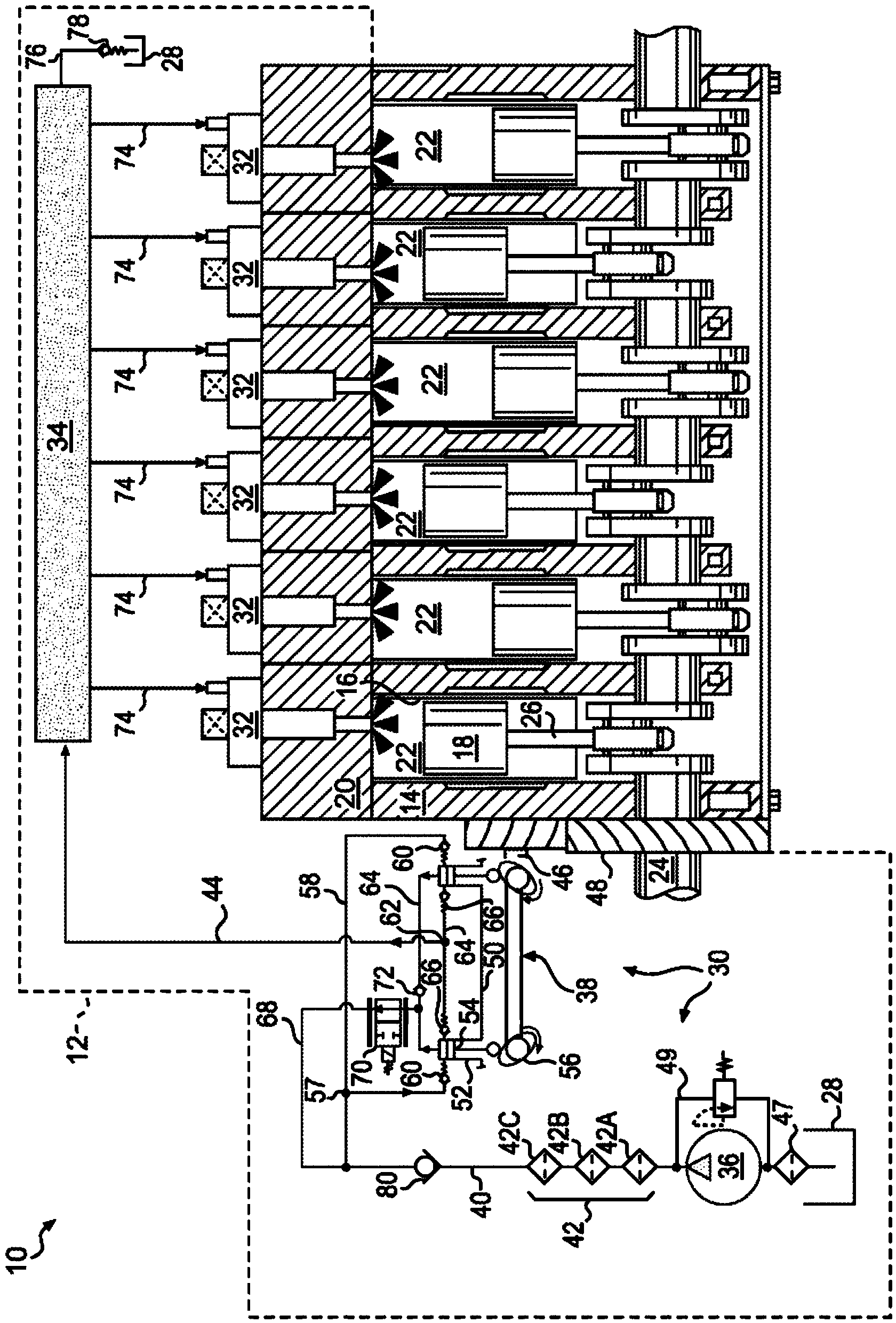

[0011] figure 1 Engine 10 is shown equipped with an exemplary embodiment of fuel system 12 . For the purposes of this disclosure, engine 10 is depicted and described as a four-stroke diesel engine. However, those skilled in the art will recognize that engine 10 may be any other type of internal combustion engine (eg, a gasoline engine). Engine 10 may include an engine block 14 at least partially defining a plurality of cylinders 16 , a piston 18 slidably disposed within each cylinder 16 , and a cylinder head 20 associated with each cylinder 16 .

[0012] Together, cylinder 16 , piston 18 and cylinder head 20 may form combustion chamber 22 . In the illustrated embodiment, engine 10 includes six combustion chambers 22 . However, it is contemplated that engine 10 may include a greater or lesser number of combustion chambers 22, and that combustion chambers 22 may be arranged in an "inline" configuration, a "V" configuration, an opposed-piston configuration, or another suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com