Flow dividing device for a condensation steam turbine having a plurality of outlets

A technology of diverting device and steam turbine, applied in safety devices, non-variable-capacity engines, mechanical equipment, etc., can solve the problems of damage to the thermodynamic efficiency of condensing steam turbines, high flow loss of steam flow, etc., to avoid flow separation, high The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

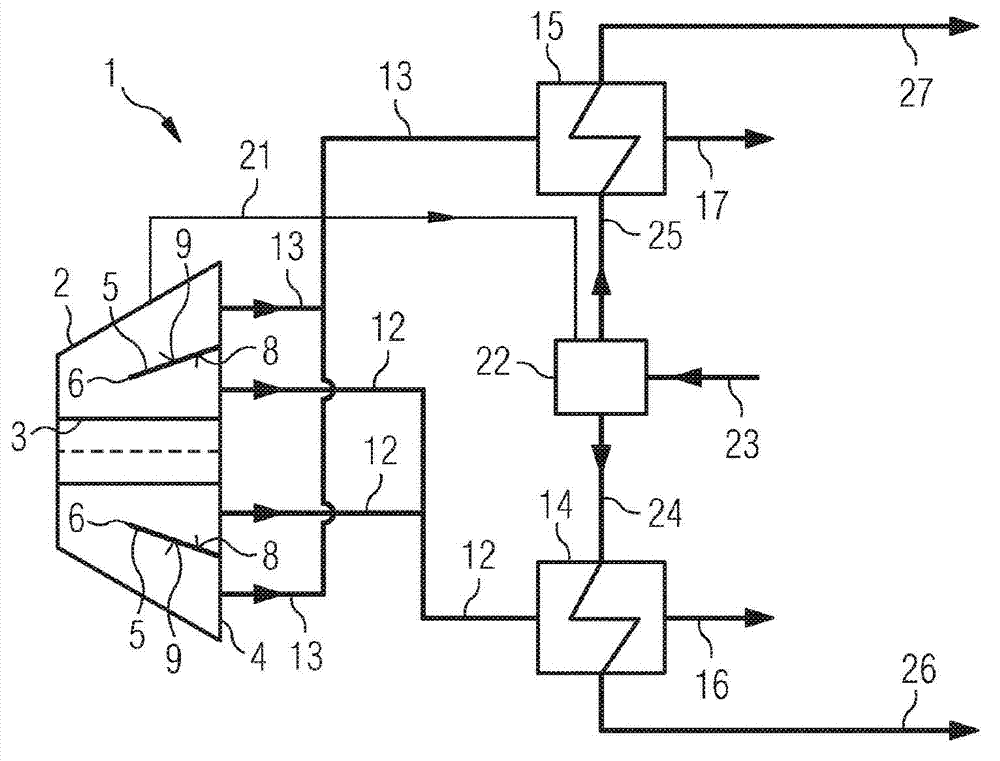

[0017] as from Figures 1 to 5 As can be seen in , the condensing steam turbine 1 has a waste steam casing 2 in which a turbine rotor 3 is arranged. During operation of the condensing steam turbine 1 , the total steam mass flow flows through the waste steam casing 2 , which leaves at the waste steam outlet 4 of the waste steam casing 2 .

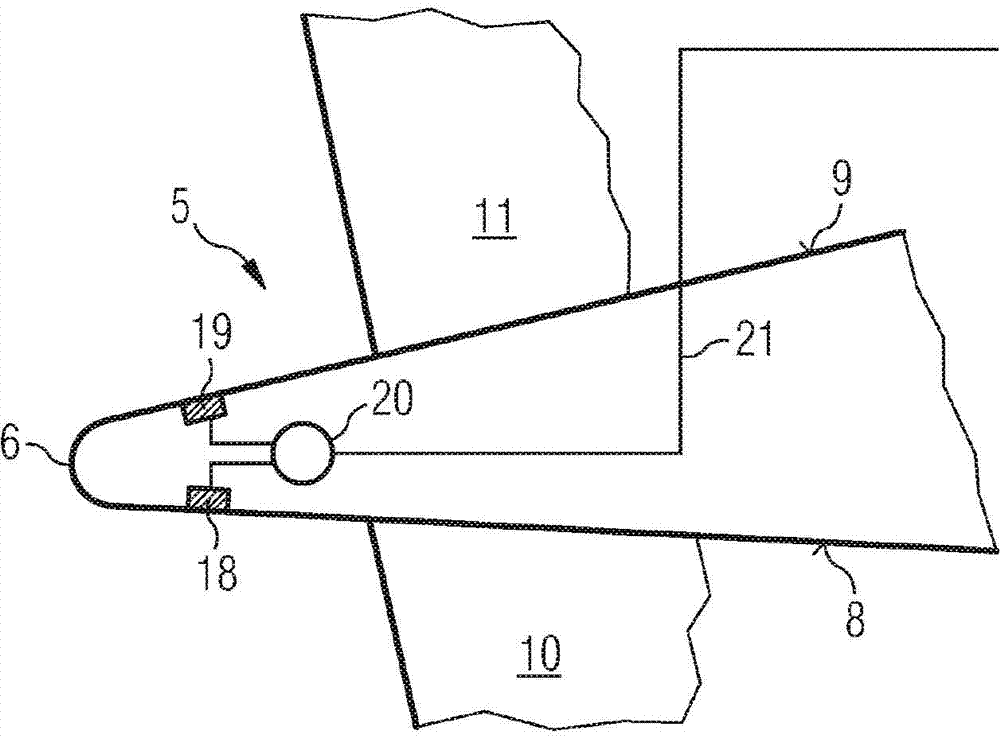

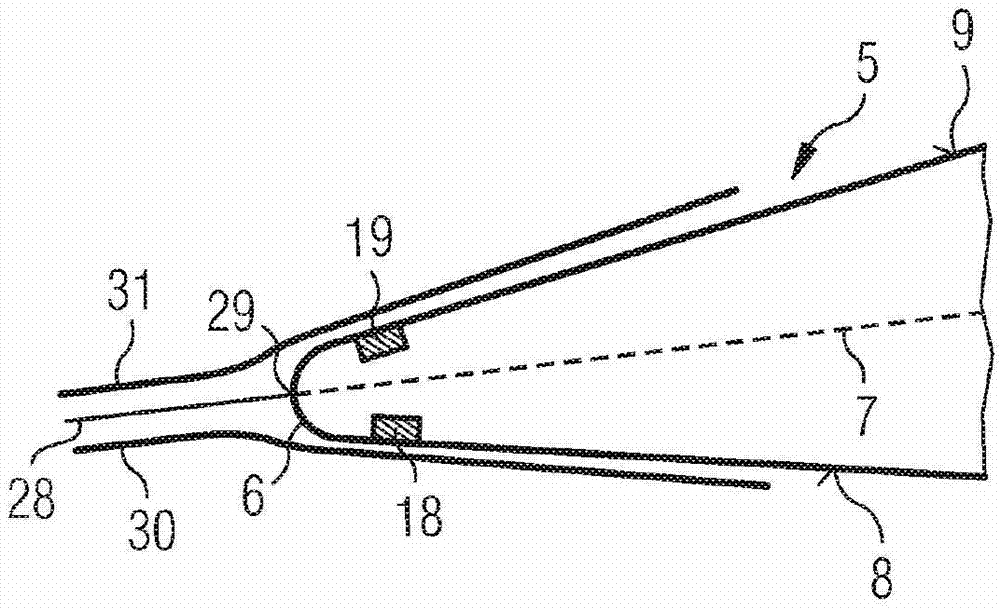

[0018] Arranged in the waste steam casing 2 is a flow divider 5 as an annular web, which is arranged coaxially around the turbine rotor 3 and divides the flow channel in the waste steam casing 2 into an inner region and an outer region. The shunt 5 has a shunt leading edge 6 in which the shunt chord ( ). The inner region of the flow channel of the waste steam casing 2 is delimited by the splitter inner side 8 and the outer region by the splitter outer side 9 , wherein the splitter inner side 8 and the splitter outer side 9 are connected at the splitter leading edge 6 .

[0019] The splitter 5 is held in the exhaust gas casing 2 by inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com