A multi-station spraying device

A spraying device and multi-station technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problem of water spraying for workpieces that cannot be selected at different stations, and the water spraying position cannot be changed, and achieve the effect of precise water spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

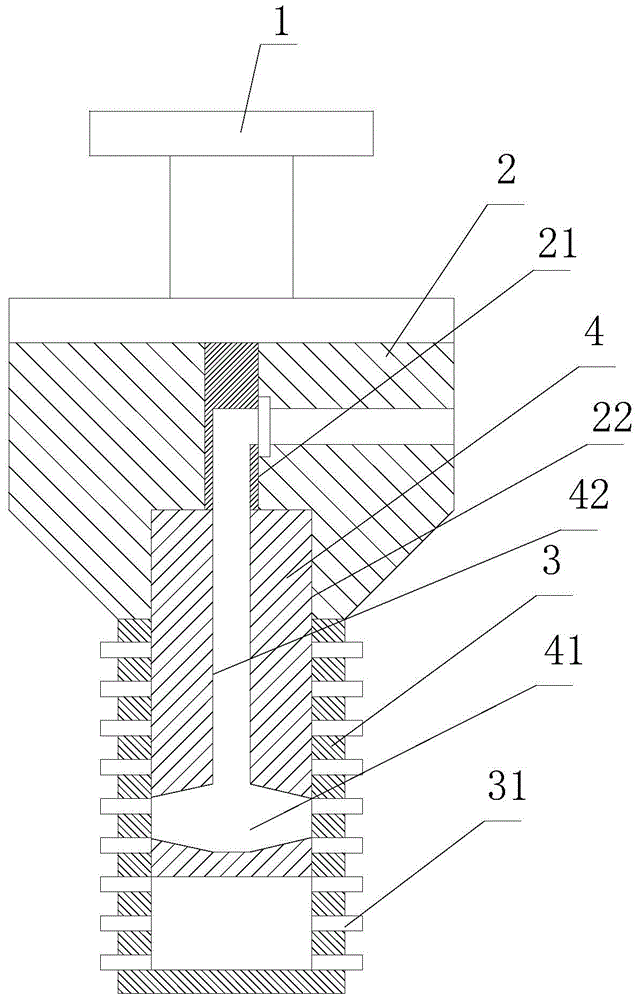

[0009] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a multi-station spraying device proposed by the present invention.

[0010] refer to figure 1 , in one embodiment, the present invention proposes a multi-station spraying device, comprising a power mechanism 1, a base 2, a water spray pipe 3, and a blocking block 4, the base 2 has a cavity running through it, the above-mentioned The cavity has a stepped structure and is divided into a first cavity 21 with a smaller inner diameter and a second cavity 22 with a larger inner diameter by the stepped structure. The water spray pipe 3 is a cylinder with one end open and the other closed. One end of the opening of the water pipe 3 is connected to one end of the second cavity 22 of the base 2 and the inner diameter of the water spray pipe 3 is equal to the inner diameter of the second cavity 22. The inner cavity of the water spray pipe and the second cavity 22 form a moving channel, and the blocking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com