Catalyst for synthesizing dimethyl oxalate through gas-phase carbonylation as well as preparation method and application of catalyst

A technology of dimethyl oxalate and chemical synthesis, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, carbon monoxide or formate reaction preparation, etc. It can solve the problems of poor selectivity of target products and high content of precious metals, and achieve good catalysis Effect, high reactivity, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

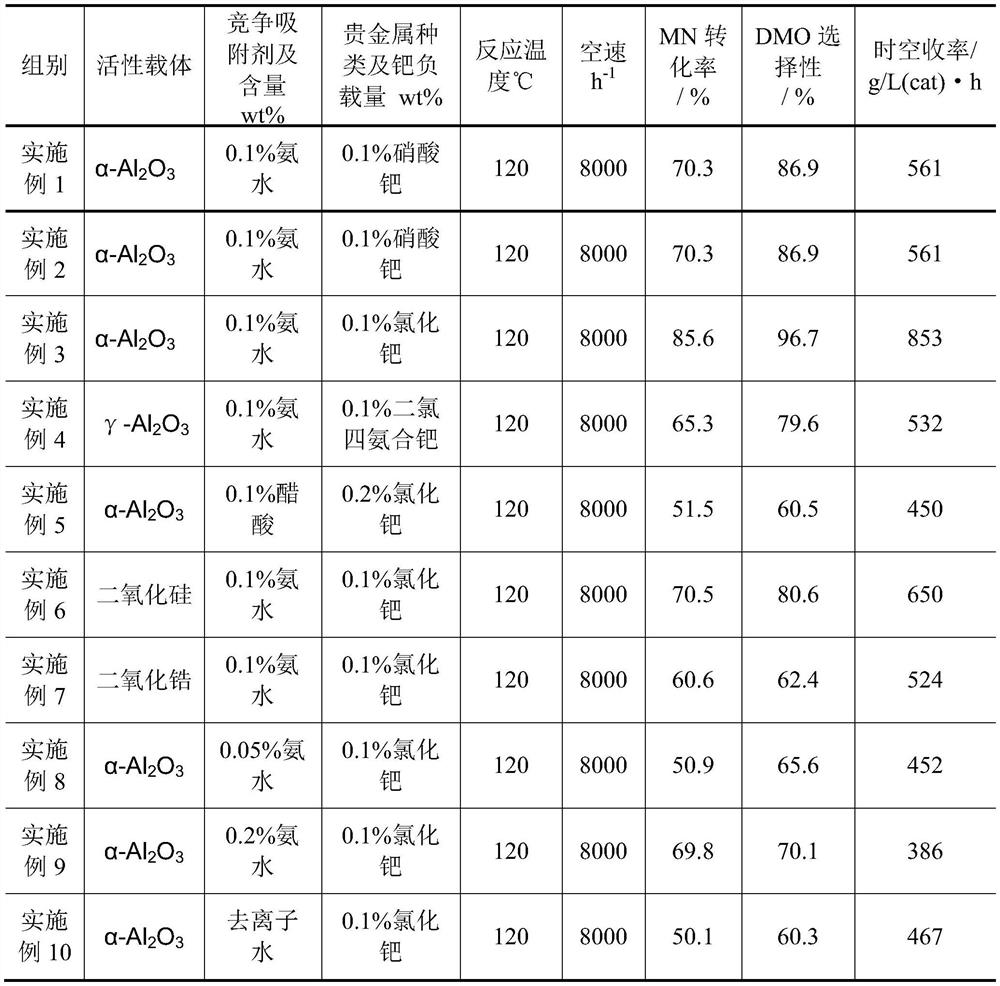

Examples

Embodiment 1

[0032] A gas-phase carbonylation catalyst for synthesizing dimethyl oxalate comprises an active component and an active carrier, wherein the active component is palladium, the active carrier is a carrier treated by a competitive adsorbent, and the competitive adsorbent is ammonia water.

[0033] Above-mentioned dimethyl oxalate catalyst is used to participate in gas-phase synthesis of dimethyl oxalate reaction, comprising the following steps:

[0034] T1, put the gas-phase carbonylation synthesis dimethyl oxalate catalyst into a fixed reactor, use 5% H 2 / N 2 to restore. Specifically, sieve the prepared catalyst tablet into 40-60 meshes, then take 1ml and put it into a fixed reactor, 2 / N 2 Medium reduction, the total flow rate is controlled at 100ml / min, the reduction temperature is 150°C, and the reduction time is 10 hours.

[0035] T2. After the reduction in step T1, the pressure is 0.2MPa, the HCl content is 100ppm, and the volume space velocity is 8000h -1 , the reac...

Embodiment 2

[0037] A kind of preparation method of gas-phase carbonylation synthetic dimethyl oxalate catalyst, comprises the following steps:

[0038] S1. Add the carrier into the competing adsorbent, seal it after stirring, let it stand for several times, stir and seal it, and filter to obtain the active carrier. Specifically, 5g of α-Al will be weighed 2 o 3 Add it into 200ml of 0.1% ammonia water, stir and seal it, let it stand for 30 minutes, stir and seal it, repeat 6 times, filter and wash to obtain the active carrier.

[0039] S2. Dissolving the palladium salt in the reducing solution, heating and stirring until the palladium salt is completely dissolved, obtaining a mixed solution and constant volume. Specifically, 0.1 g of palladium nitrate was weighed and added to 10 mL of concentrated nitric acid solution, heated and dissolved on an electric furnace until the palladium nitrate was completely dissolved, and cooled to 100 mL to obtain a mixed solution.

[0040] S3. Add the ac...

Embodiment 3

[0046] A catalyst for synthesizing dimethyl oxalate by gas-phase carbonylation. The components of the catalyst for synthesizing dimethyl oxalate by gas-phase carbonylation in this embodiment are the same as those in Example 1, and will not be repeated here.

[0047] In the present embodiment, also provide a kind of preparation method of gas-phase carbonylation synthesis dimethyl oxalate catalyst, comprise the following steps:

[0048] S1. Add the carrier into the competing adsorbent, seal it after stirring, let it stand for several times, stir and seal it, and filter to obtain the active carrier. Specifically, 5g of α-Al will be weighed 2 o 3 Add it into 200ml of 0.1% ammonia water, stir and seal it, let it stand for 30 minutes, stir and seal it, repeat 6 times, filter and wash to obtain the active carrier.

[0049] S2. Dissolving the palladium salt in the reducing solution, heating and stirring until the palladium salt is completely dissolved, obtaining a mixed solution and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com