A dispensing pressurizing mechanism

A pressurizing mechanism and glue dispensing technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of affecting the yield, large operation error, low efficiency, etc., and achieve the effect of easy control and smooth glue discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

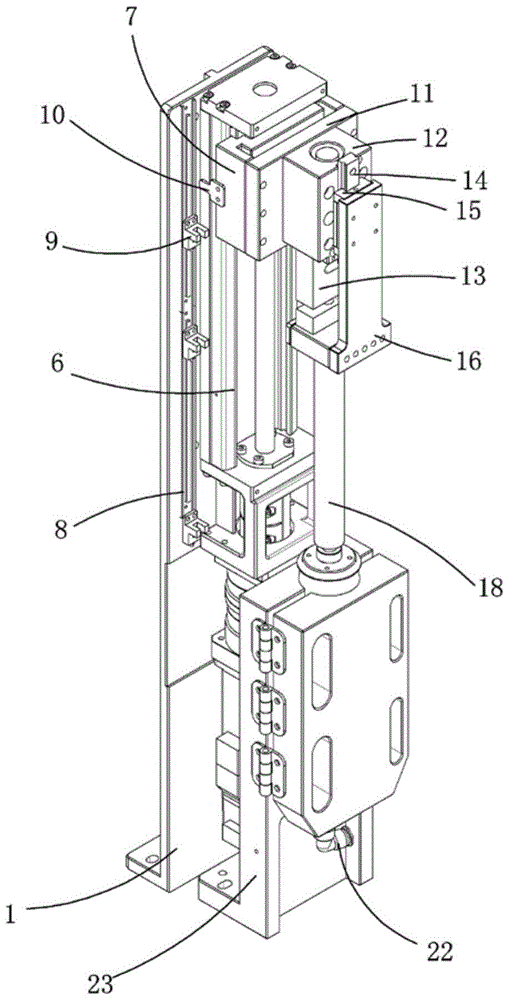

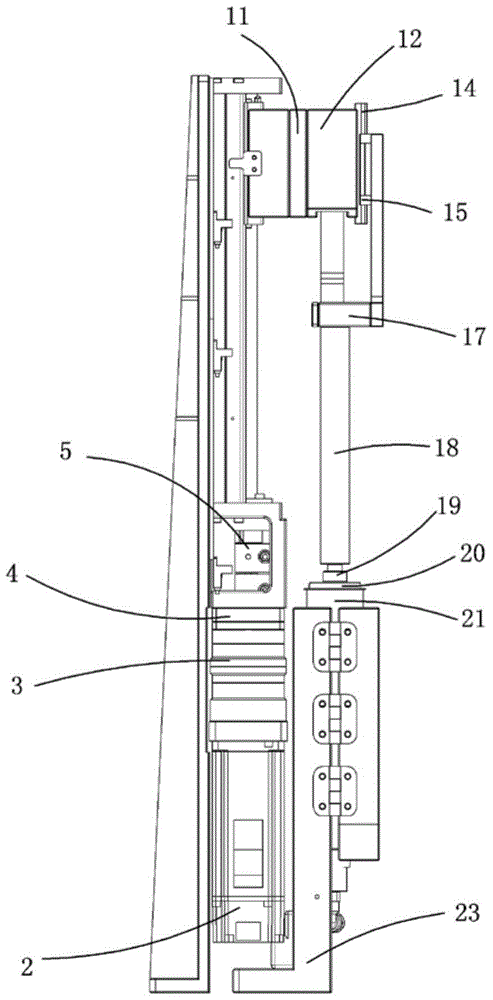

[0020] Examples, see attached figure 1 and 2 , a dispensing and pressing mechanism, which includes a mounting base 1, a motor 2, a reducer 3, a reducer connecting plate 4, a coupling 5, a linear module 6 and a linear module slider 7, the linear module Installed on the mounting base, the motor is installed on the reducer, the reducer is installed on the linear module through the reducer connecting plate, and connected with the linear module through the coupling; the linear module is matched with the installation There is a linear module slider, and the motor drive can drive the linear module slider to move up and down along the linear module.

[0021] A mounting bar 8 is installed on the mounting base, and three photoelectric sensors 9 are installed on the mounting bar. The side of the linear module slide block is equipped with an induction sheet 10 matched with the photoelectric sensor, and the distance that the linear module moves up and down is determined by The photoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com