Thermoforming Folding Clamping Device

A technology of thermoforming and inserting material, which is applied in the field of thermoforming, can solve the problems of automatic feeding, thinning of both ends, and deformation of surface texture, etc., and achieve the advantages of saving raw materials, increasing product thickness, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

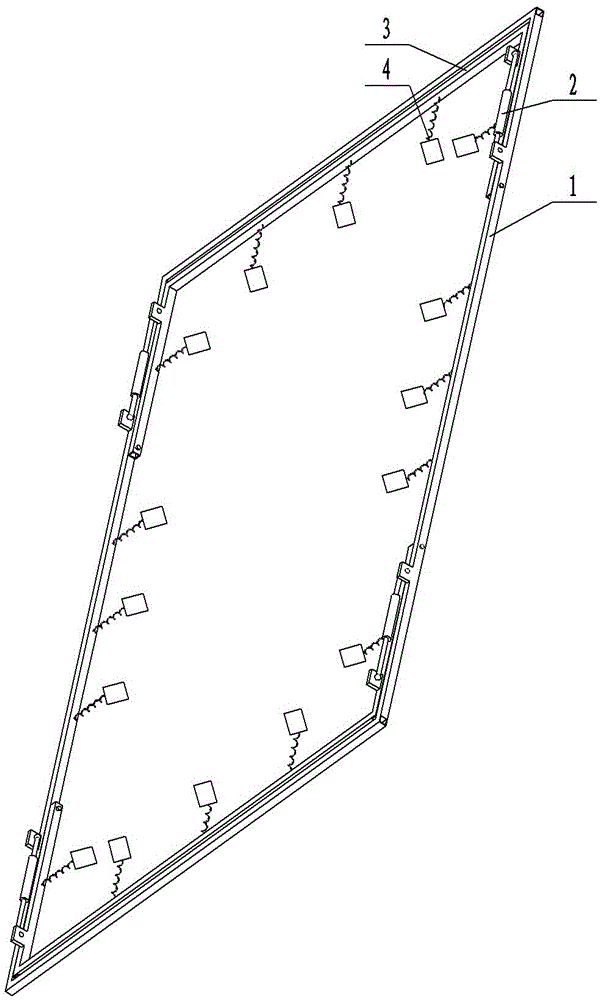

[0015] figure 1 The shown thermoforming folding clamping device mainly includes a fixed frame 1, a gas spring 2, a movable fork 3 and an elastic clamping part 4; the fixed frame 1 is a rectangular frame, and two The movable fork 3, the fork end of each movable fork 3 is hinged with the fixed frame 1, the two forks of the movable fork 3 are connected with the fixed frame 1 through the gas spring 2, and one end of the gas spring 2 is connected with the fixed frame 1. The fixed frame 1 is hinged, and the other end is hinged with the yoke of the movable yoke 3. In order to facilitate installation and provide enough space for activities, a raised connecting ear is fixed on the upper surface of the fixed frame 1 and the movable yoke 3. The springs 2 are respectively rotatably mounted on the corresponding connecting lugs; when the gas spring 2 is in a natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com