Novel aluminum-alloy ribbing automobile fuel tank

A technology of aluminum alloy and fuel tank, which is applied in the direction of vehicle components, the arrangement combined with the fuel supply of internal combustion engines, power devices, etc., and can solve the problems of internal partition falling off and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

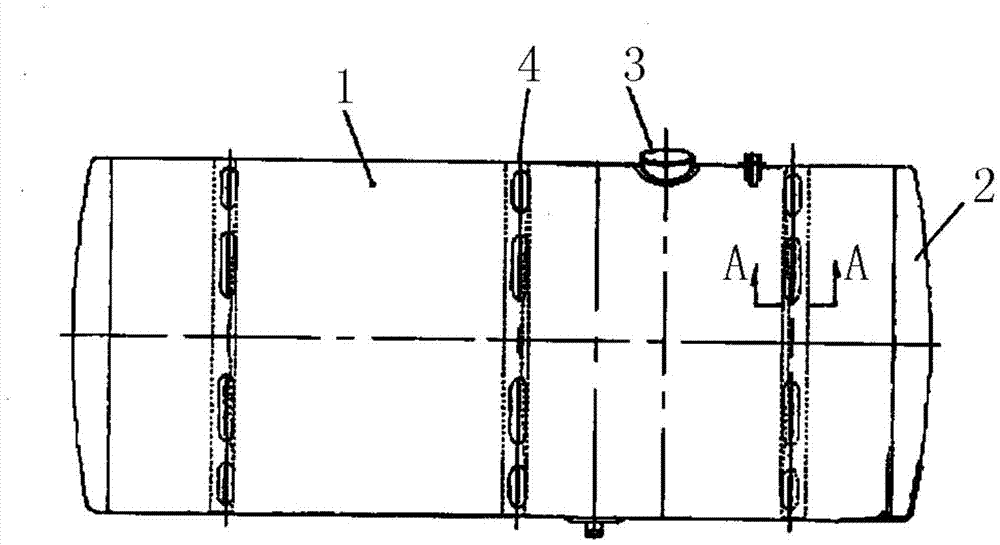

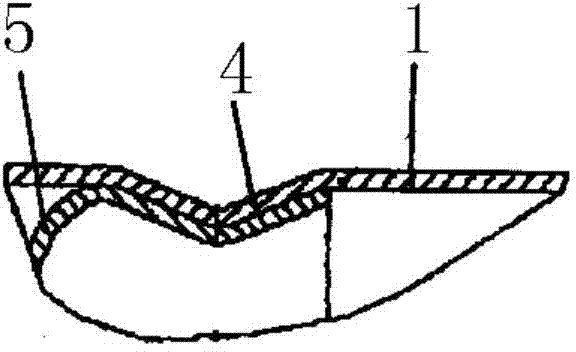

[0010] like figure 1 , 2 As shown, in the present invention, end caps 2 are engaged respectively at both ends of the cylinder body 1, and the fuel filling port 3 is arranged on the upper part of one side of the cylinder body 1, and a plurality of beading ribs 4 are pressed on the surface of the cylinder body 1 , an inner partition 5 is spaced at the corresponding position of the inner bead 4 of the cylinder body 1 , and the edge of the inner partition 5 is riveted and connected with the bead 4 on the cylinder body 1 . Through the above settings, the connection between the inner baffle 5 and the cylinder 1 of the present invention is more reliable and firm, and the inner baffle 5 reduces the shock of the oil liquid generated when the vehicle is running, effectively reducing the impact of the oil on the inner wall of the cylinder 1, and more The presence of the bead 4 also strengthens the strength of the cylinder body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com