Drum-type yarn hanging vehicle

A wire-hanging car and drum-type technology, which is applied in the field of handling tools, can solve the problems of limited number of hanging wires, increase the number of wire-hanging cars used, and increase the workload of workers, so as to reduce workload, prevent rollover, and prevent wire entanglement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

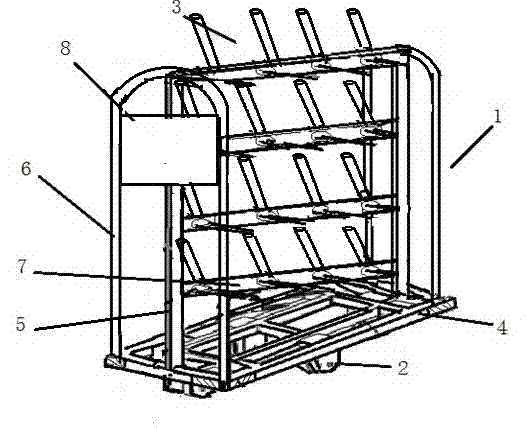

[0013] like figure 1 A drum-type wire-hanging car is shown, which includes a vehicle frame 1, wheels 2 and a drum-type wire-hanging frame 3, wherein the vehicle frame 1 includes a base 4, two vertical frames 5, uprights 6 and beams 7 The wheel 2 is a fully enclosed caster, which is installed under the base 4, and the cylindrical wire rack 3 adopts a cylindrical drum type wire rack, which is welded to the beam 7, the crossbeam 7 is welded between the two vertical frames 5; the vertical frame 5 is welded vertically to the center of the left and right symmetry axes of the base 4, and the vertical frame 5 is provided with There is a label 8, the inside of the label 8 is aluminum alloy, and the outer layer is a transparent color ferrule; the column 6 is an inverted U shape, and the end of the horizontal section of the column 6 is welded to the vertical On the straight frame 5 , the end of the vertical section is welded to the corner of the base 4 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap