Elevator safety protection device for preventing cage from accidental movement and working method of elevator safety protection device

A safety protection device and accidental movement technology, which is applied to elevators, transportation and packaging, elevators, etc. in buildings, can solve problems such as poor practicability, and achieve the effects of strong practicability, low cost, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

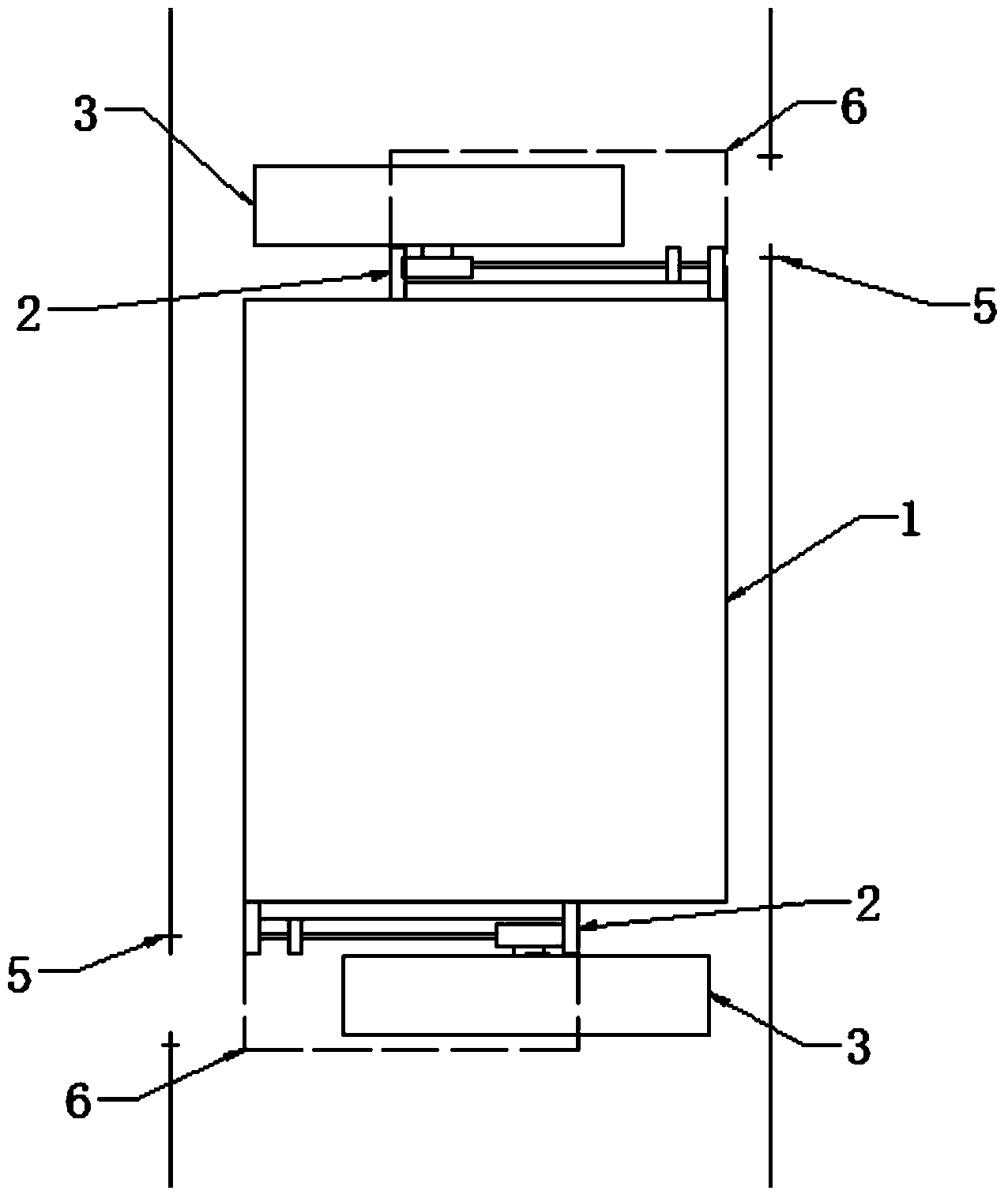

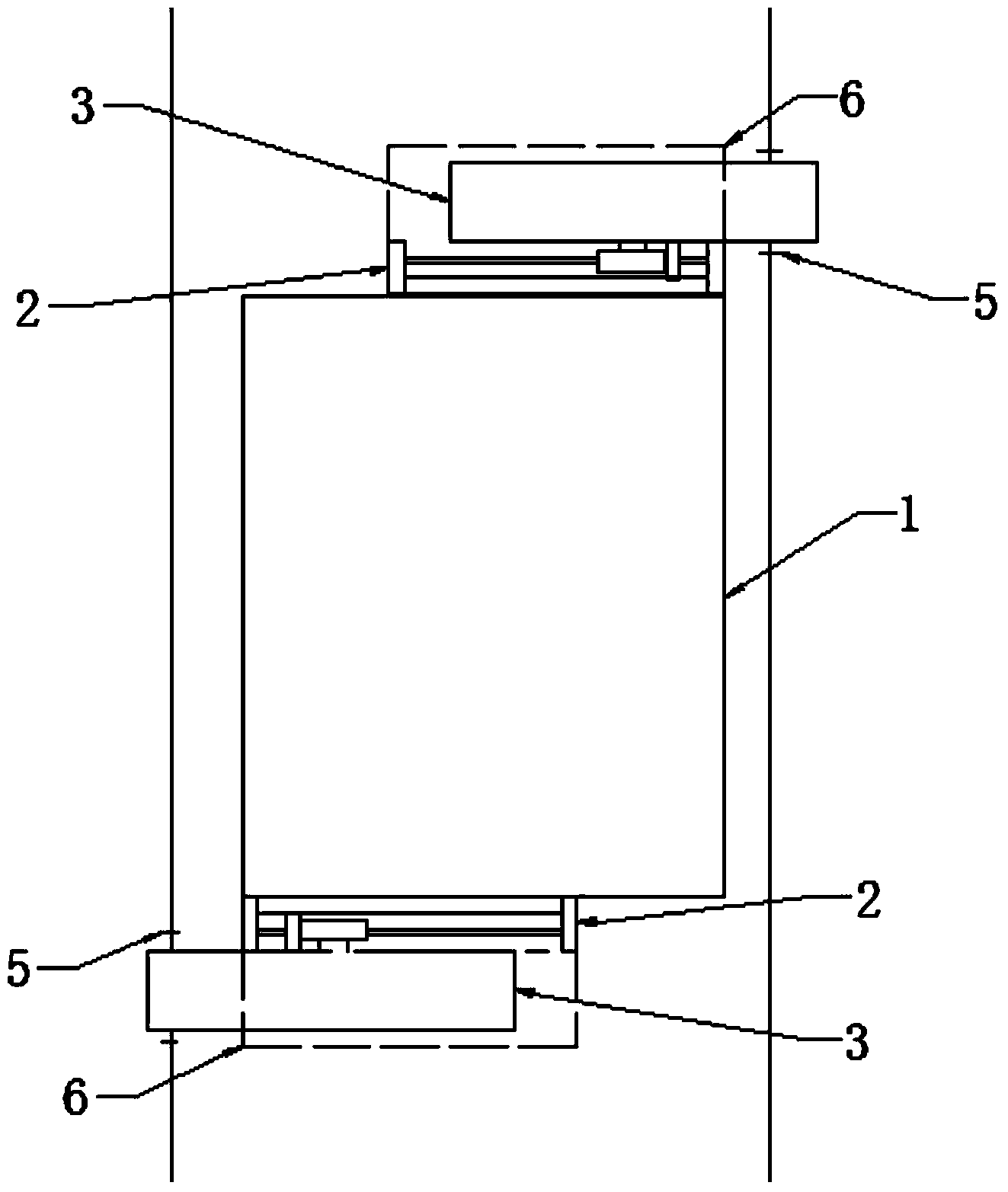

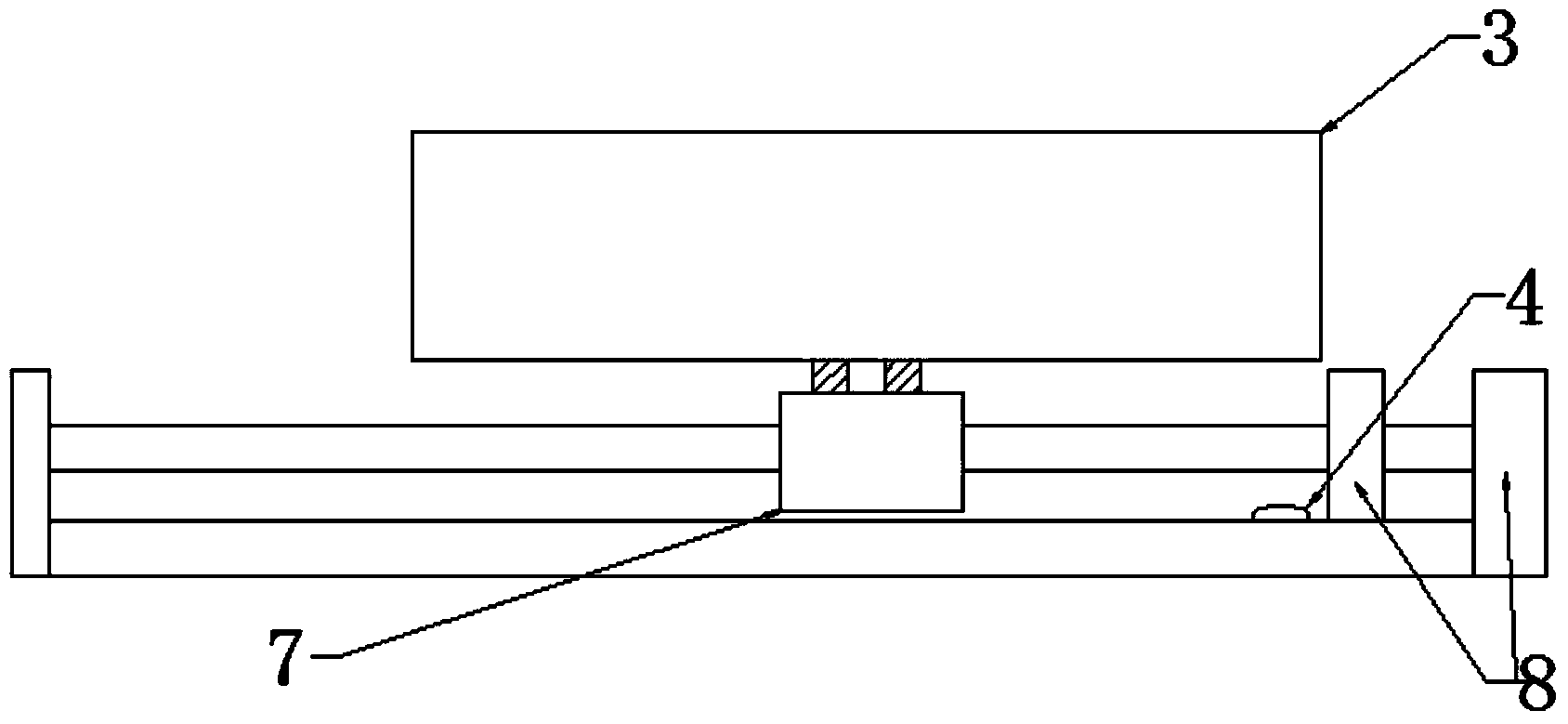

[0026] Embodiment: An elevator safety protection device for preventing accidental movement of the car, which is characterized in that it includes a pair of double-axis ball screw track slides 2, a pair of steel bars 3, a pair of protective covers 6, a pair of control switches 4, stepper motor driver and motor controller, the pair of protective covers 6 are respectively fixed on the top and bottom of the car 1, the double-axis ball screw track slide 1 is fixed in the protective cover 6, and the square steel 3 is fixed On the movable slider 7 of the double-axis ball screw track slide 2, the slideway of the double-axis ball screw track slide 2 on the top of the car 1 is provided with a control switch 4 for controlling the power on and off of the car door , the slideway of the double-axis ball screw track slide table 2 at the bottom of the car 1 is provided with a control switch 4 for controlling the power on and off of the leveling door, and a square steel hole 5 is provided in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com