Heat radiation drainage passage for extrusion forming machine drainage system

A technology of drainage system and molding machine, which is applied in the direction of waterway system, sewer system, water supply device, etc., can solve the problem of unsmooth water flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

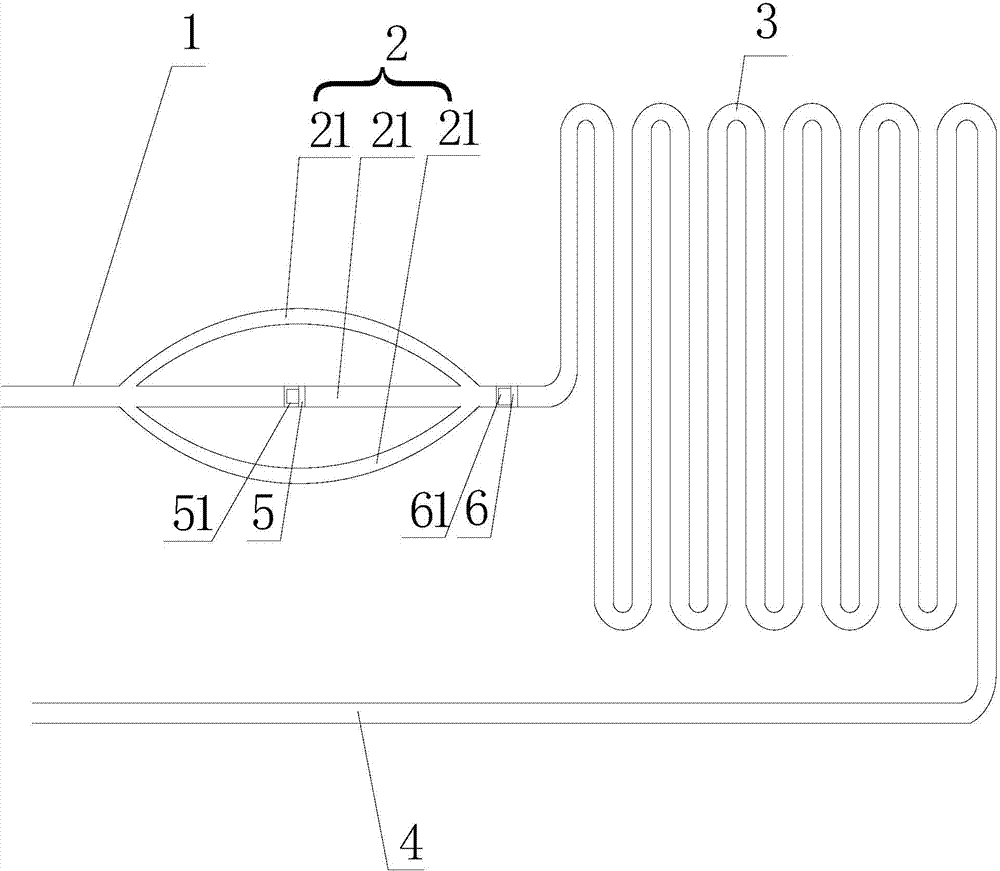

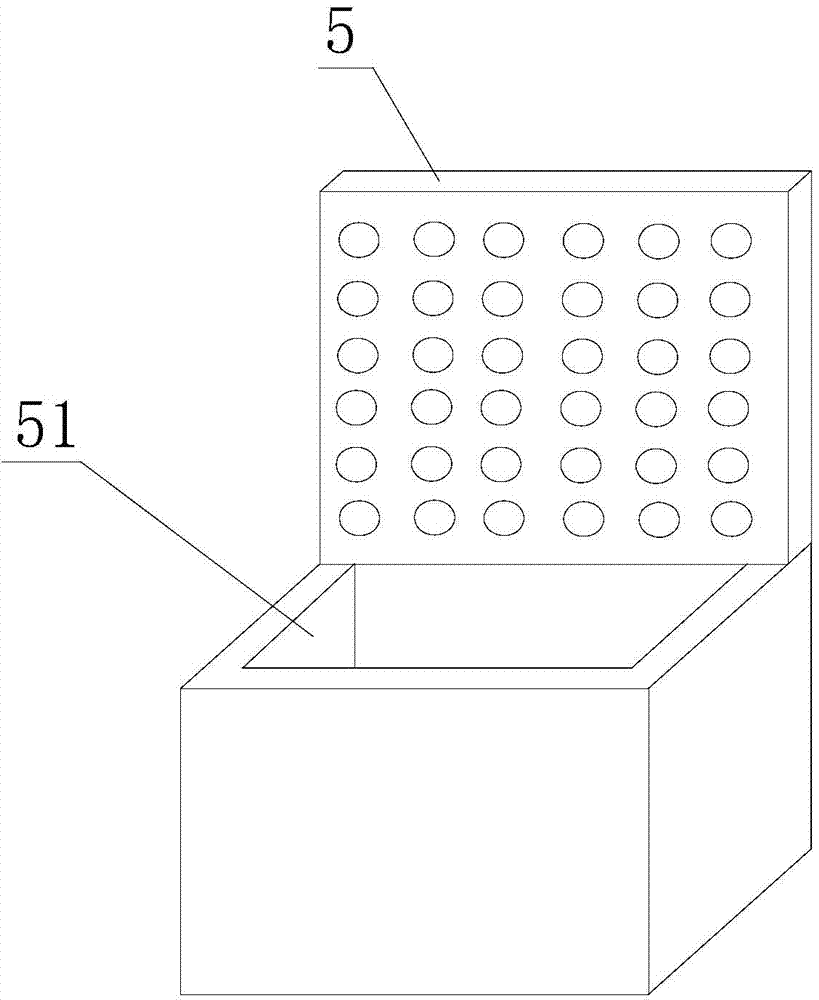

[0013] refer to figure 1 and figure 2 , the heat dissipation drainage channel for the drainage system of the extrusion molding machine, including a channel connected to the drainage pipe and opened on the ground, the channel is composed of the first channel 1, the second channel 2, the third channel 3 and the fourth channel connected in sequence 4; the first channel 1 is a straight channel connected with the drain pipe; the second channel 2 is composed of three side-by-side sub-channels 21, and the middle sub-channel 21 is aligned with the first channel and is a straight channel. The two sub-channels 21 also communicate with the first channel 1; the third channel 3 is a curved channel that communicates with the three sub-channels 21; the fourth channel 4 is a straight channel for water recycling; the middle sub-channel 21 A first filter 5 for intercepting waste is provided inside, and a second filter 6 for intercepting waste is provided at the entrance of the third channel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com