Variable geometry turbine

A turbine, geometric technology, used in mechanical equipment, engine components, engine manufacturing, etc., to solve problems such as pressure fluctuations or oscillations, and achieve easily predictable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

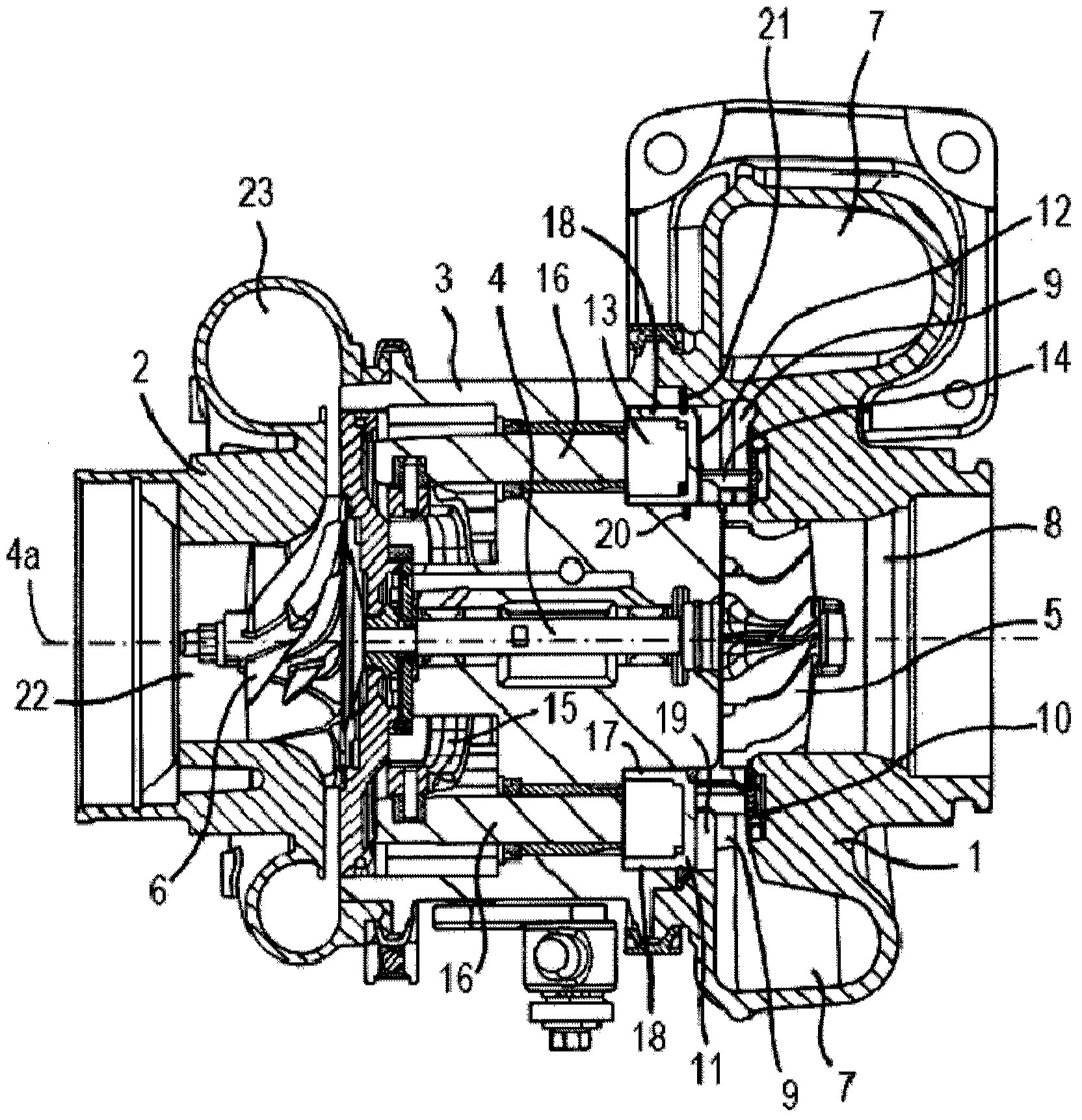

[0117] refer to figure 1 , which shows a known variable geometry turbocharger comprising a variable geometry turbine housing 1 and a compressor housing 2 interconnected with it via a central bearing housing 3 . The turbocharger shaft 4 extends from the turbine housing 1 through the bearing housing 3 to the compressor housing 2 . A turbine wheel 5 is mounted on one end of the shaft 4 for rotation inside the turbine housing 1 , and a compressor wheel 6 is mounted on the other end of the shaft 4 for rotation inside the compressor housing 2 . The shaft 4 rotates about a turbocharger axis 4 a on a bearing assembly located in the bearing housing 3 .

[0118] The turbine housing 1 defines an intake volute 7 and to which gas is delivered from an internal combustion engine (not shown). Exhaust gas flows from the intake volute 7 via the annular inlet passage 9 and the turbine wheel 5 to the axial outlet passage 8 . Said inlet passage 9 is delimited at one end by the radial wall surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com