Motor-assisted variable geometry turbocharging system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

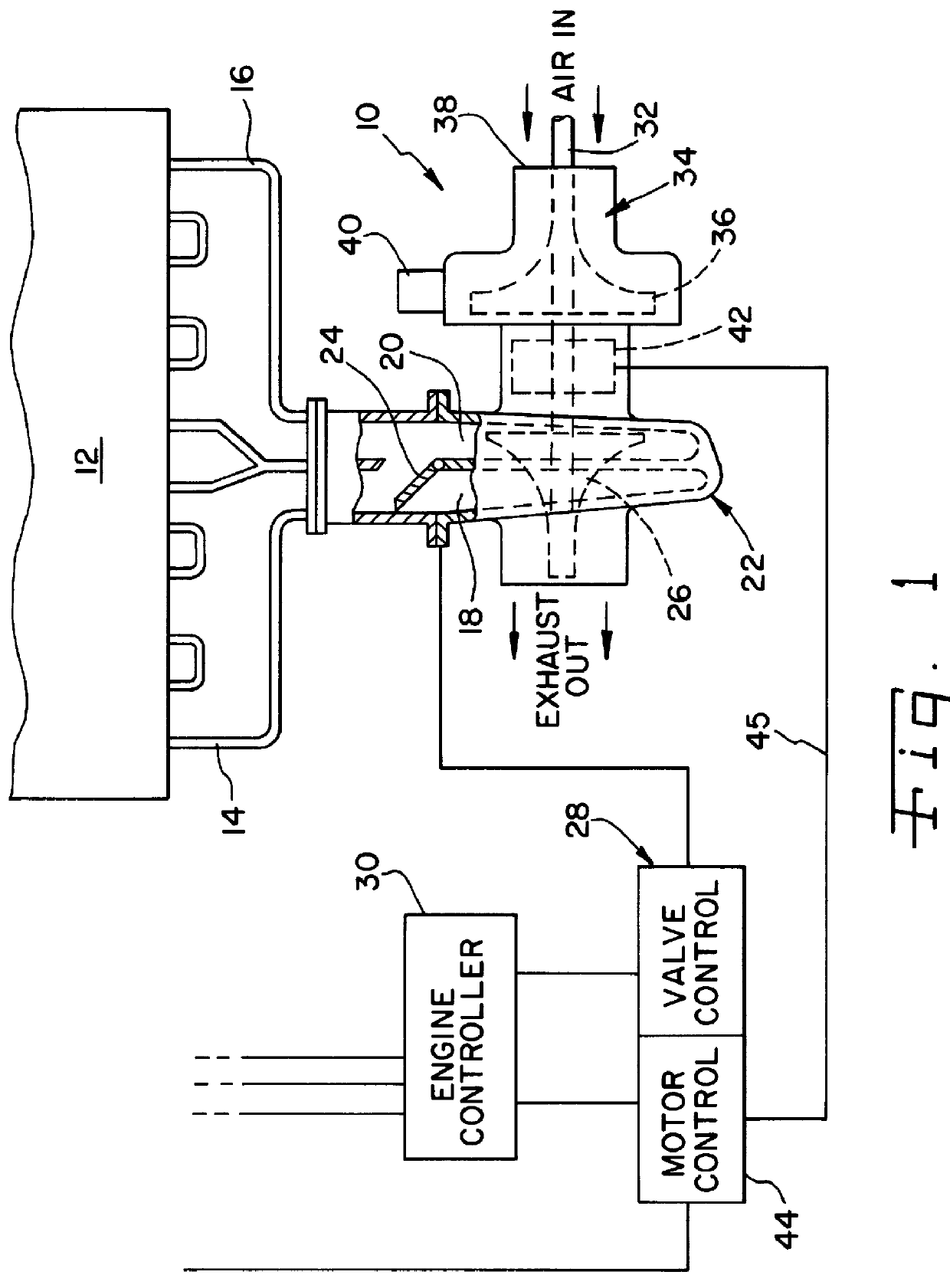

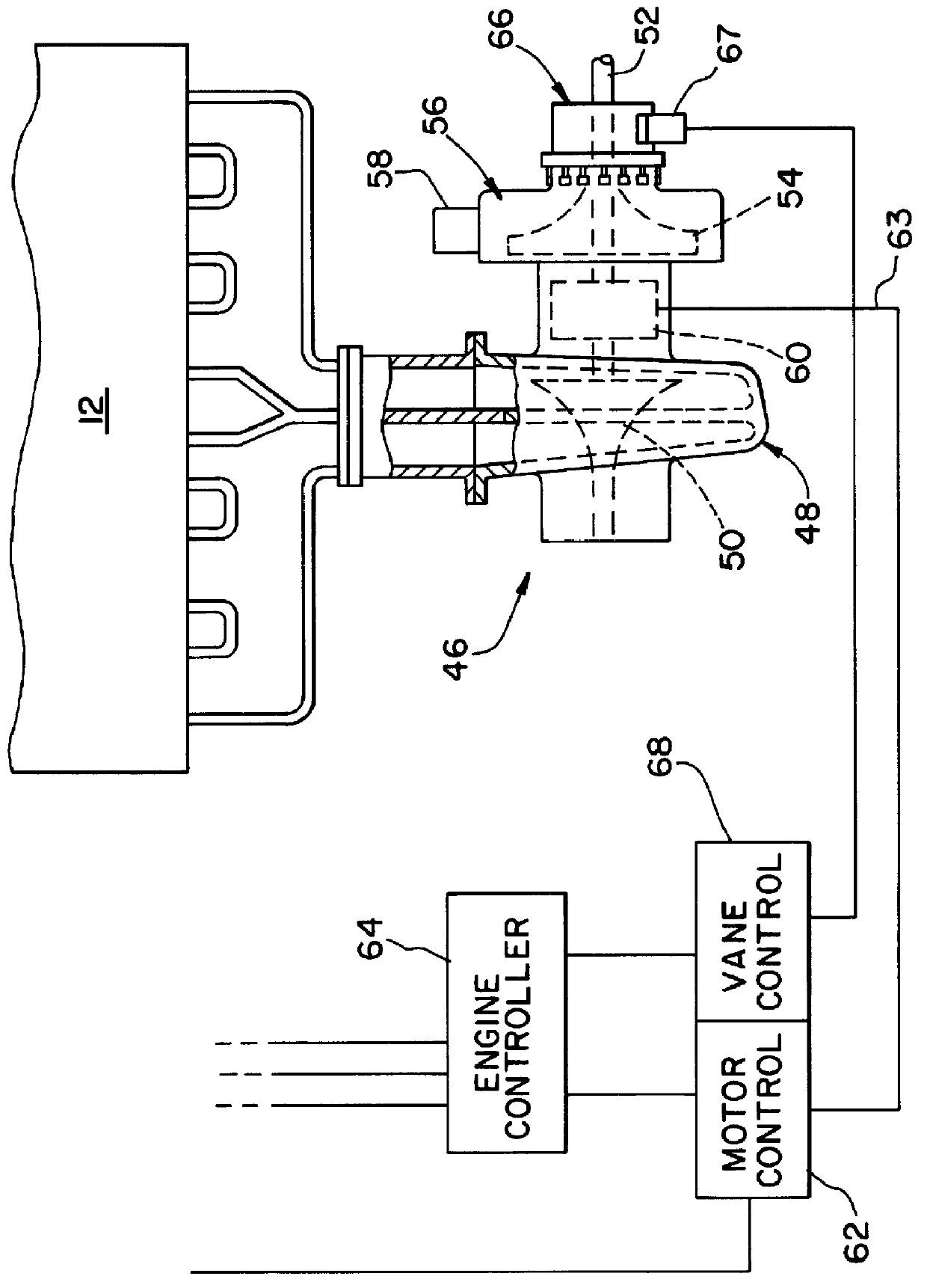

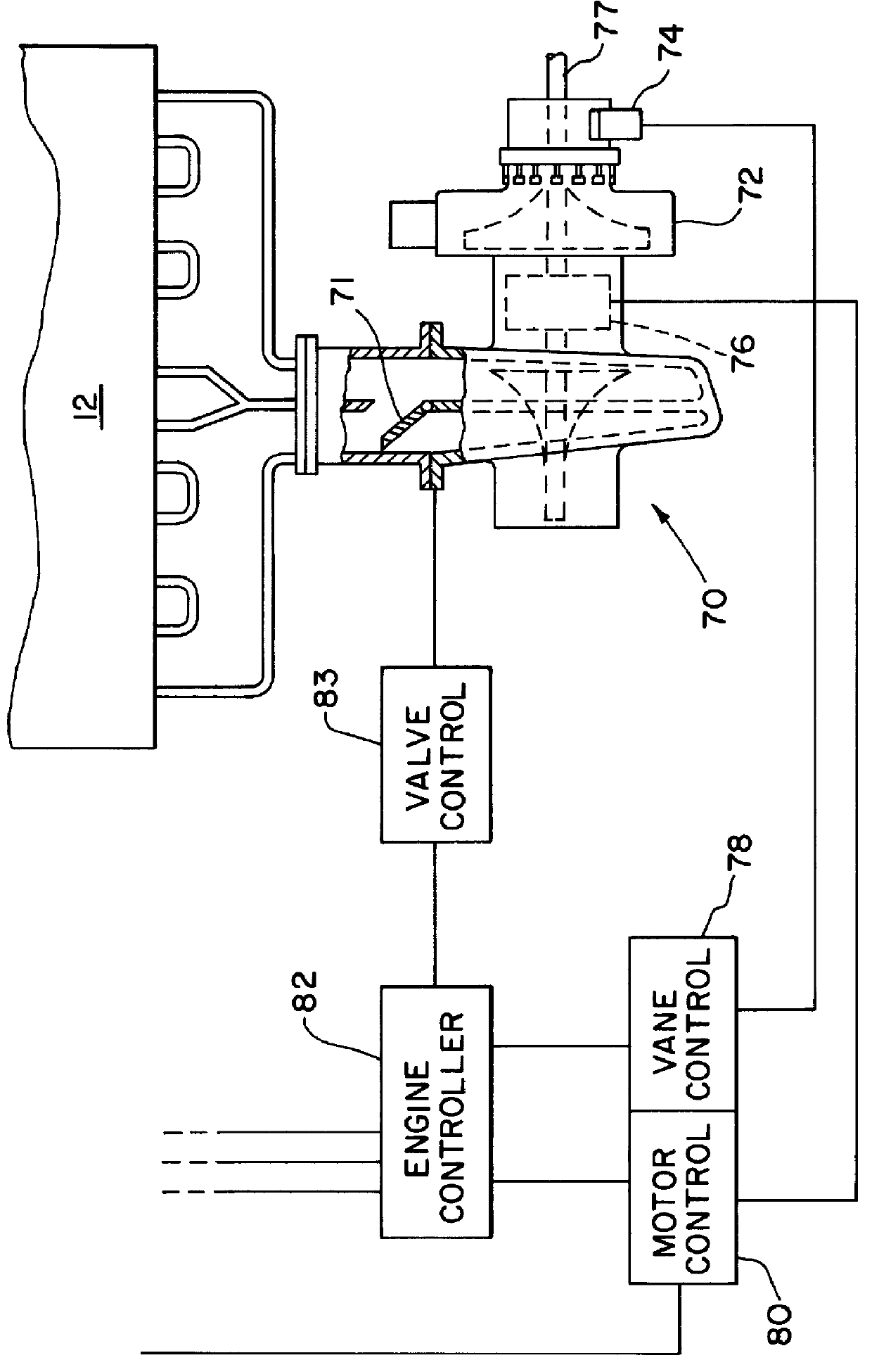

To improve engine and vehicle response to opening of the throttle, an external power source is needed to operate the turbocharger at higher speed at engine idle in order to provide increased boost levels in the engine intake system in preparation for quick acceleration. This external power source can be any convenient rotating power source, such as an electric motor, a hydraulic motor, a pneumatic motor, or the like, and particularly a motor which can have its power output controlled. A preferred example and the example given below of an external power source is an electric motor that engages the turbocharger rotor at engine idle and increases the idle speed of rotation of the rotating assembly.

Having higher boost pressure available at engine idle speed than the boost pressure the turbocharger can provide from exhaust gas energy alone, allows fuel to be injected into the engine cylinders sooner during acceleration and reduces smoke and emissions during the transient period. The engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com