Built-in tool magazine

A built-in tool magazine technology, applied in the field of built-in tool magazine, can solve problems such as not obvious effect, impact of machine size, external image impact, etc., and achieve the effect of simple structure, smooth tool change and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

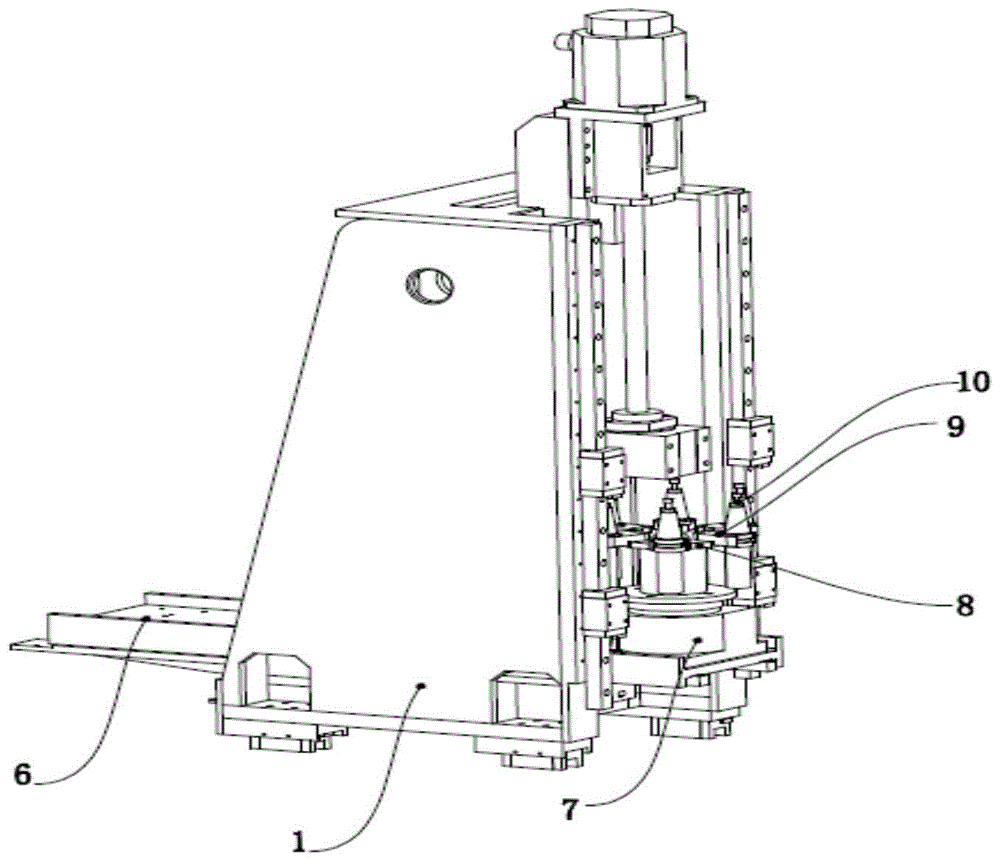

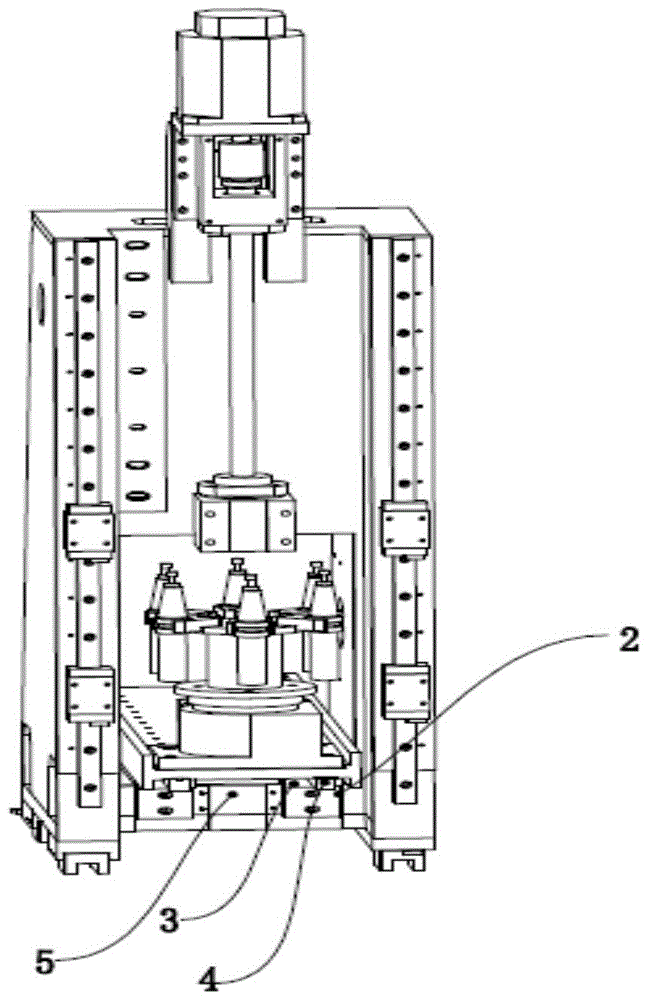

[0021] The built-in tool magazine includes a cutter head 8, a tool holder 9 and a knife handle 10, and the tool holder 9 is installed on the cutter head 8 and clamps the knife handle 10; it also includes a column 1, a driving device, a knife handle Library mobile support 6, telescopic shield and shield control device; the cutter head 8 is installed on the knife magazine mobile support 6, and one end of the knife magazine mobile support 6 is arranged in the hollow interior of the column 1, and the The driving device drives the rotation of the cutter head 8 ; the telescopic shield is arranged on the top of the column 1 , and the shield control device controls the telescopic shield to move up and down in the hollow of the column 1 .

[0022] During the processing, the cutter head 8, the tool holder 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com