A nut implanting mechanism

A nut and nut body technology, which is applied to the field of mechanisms for implanting nuts into plastic parts, can solve the problems of insufficient occlusal force, the nut and the plastic are not easily fully engaged, the nut is easy to fall off, etc., and the effect of low cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

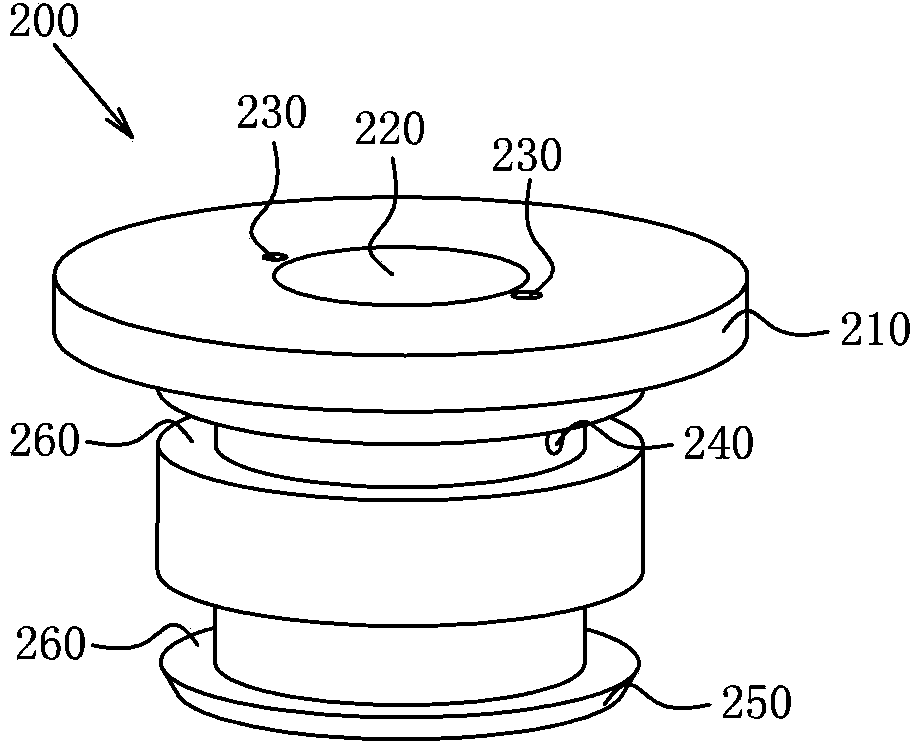

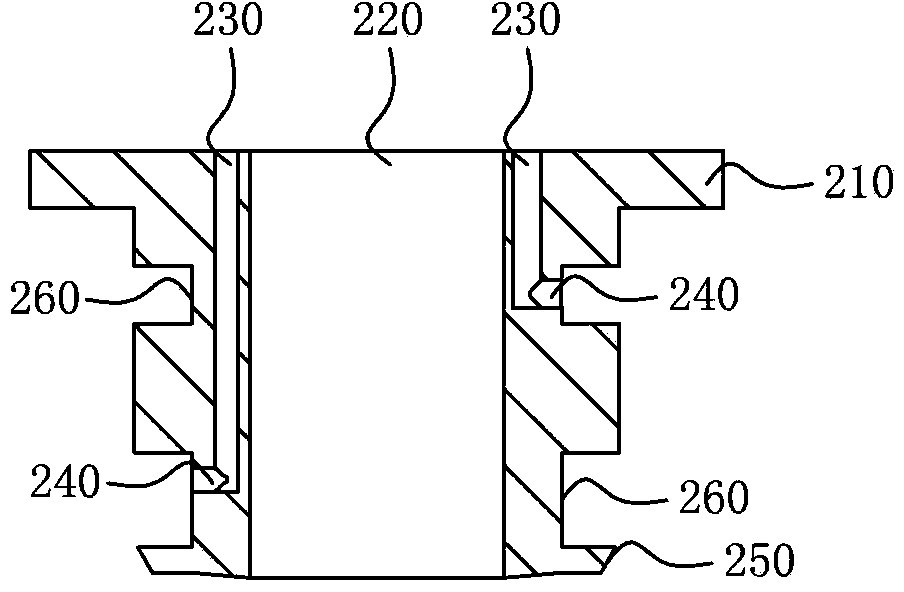

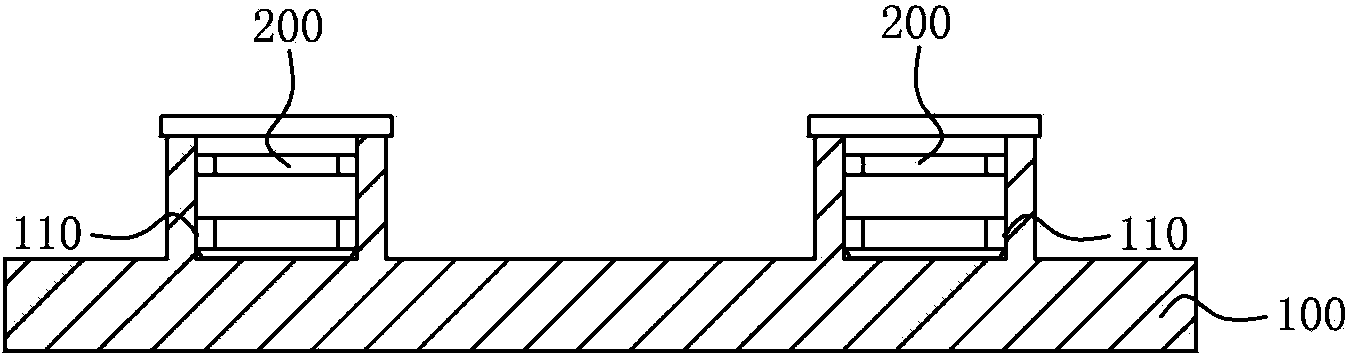

[0017] Please refer to figure 1 , figure 2 and image 3 As shown, they respectively depict a three-dimensional schematic diagram of the nut in the nut implantation mechanism of the present invention, a schematic cross-sectional view of the nut in the nut implantation mechanism of the present invention, and a structural schematic diagram of the nut implantation mechanism of the present invention.

[0018] In this embodiment, the nut implantation mechanism of the present invention is used to implant the nut 200 into the plastic part 100, the nut implantation mechanism includes:

[0019] The plastic part 100 is provided with a hollow column 110;

[0020] Nut 200, which is arranged in the hollow column 110, the nut 200 has a nut body 210 and a screw hole 220 passing through the nut body 210 and having an internal thread, and at least two glue inlets are provided on the side wall of the nut body 210 Groove 230, glue is injected in this glue feeding groove 230, and this glue can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com