A kind of PC thermal insulation integrated board construction method

A construction method and integrated panel technology, applied in the direction of thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of heavy workload, discontinuous thermal insulation, mildew on the wall, etc., achieve high connection strength, reduce on-site workload, and smooth The effect of degree increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment is an exemplary embodiment of the present invention.

[0066] A PC thermal insulation integrated board construction method of the present invention comprises the following steps:

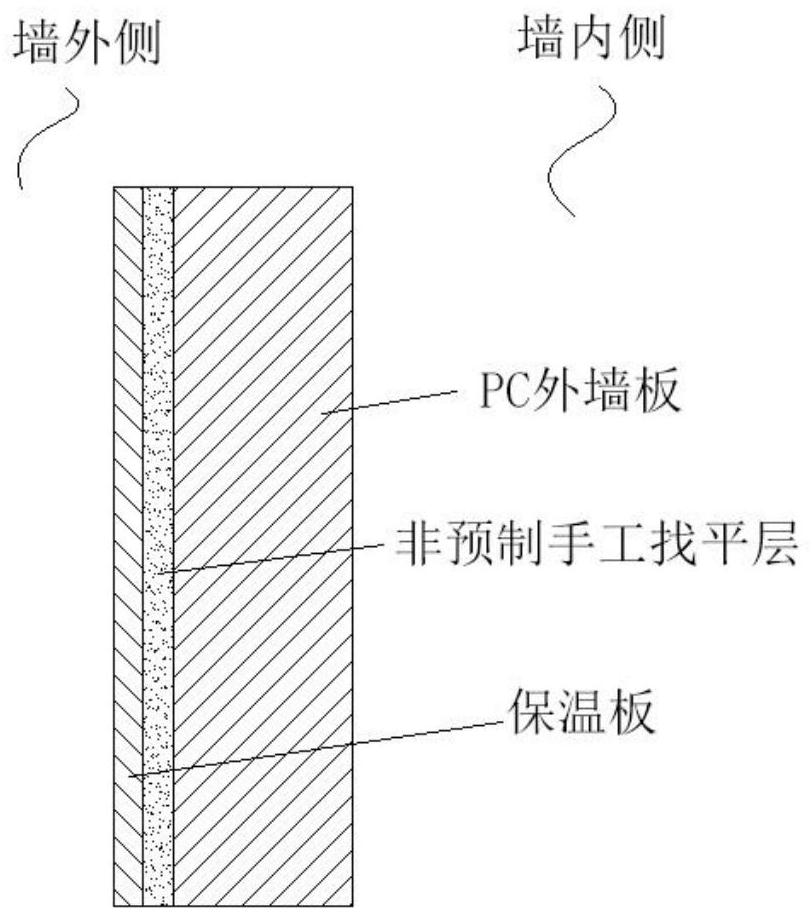

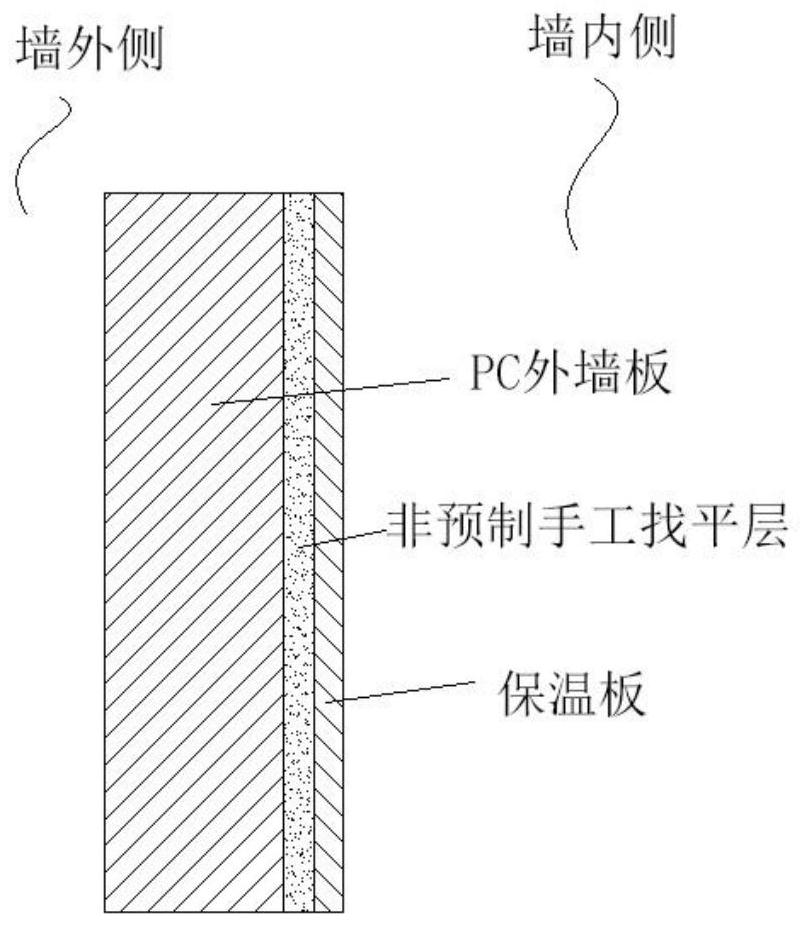

[0067] Step S202, place two adjacent PC thermal insulation integrated boards at a preset position, and form a splicing joint between the two adjacent PC thermal insulation integrated boards, wherein the PC thermal insulation integrated board includes a thermal insulation board and a wall board, and the wall board It is fixedly arranged on the inner end face of the thermal insulation board, and the distance between at least one edge of the thermal insulation board of the thermal insulation board and the edge of the wall board corresponding to the edge of the thermal insulation board is 0-600 mm;

[0068] Step S204, setting a sealing unit at the outer end of the seam;

[0069] Step S206, a fixing unit is arranged at the outer end of the splicing seam, and the fixing unit is res...

Embodiment 2

[0101] This embodiment is an exemplary embodiment of the present invention.

[0102] A PC thermal insulation integrated board construction method of the present invention comprises:

[0103] Step S302, place two adjacent PC thermal insulation integrated boards at a preset position, and form a splicing joint between the two adjacent PC thermal insulation integrated boards, wherein the PC thermal insulation integrated board includes a thermal insulation board and a wall board, and the wall board It is fixedly arranged on the inner end face of the thermal insulation board, and the distance between at least one edge of the thermal insulation board of the thermal insulation board and the edge of the wall board corresponding to the edge of the thermal insulation board is 0-600 mm;

[0104] Step S304, setting a sealing unit at the outer end of the seam;

[0105]Step S306, a fixing unit is arranged at the outer end of the splicing seam, and the fixing unit is respectively connected w...

Embodiment 3

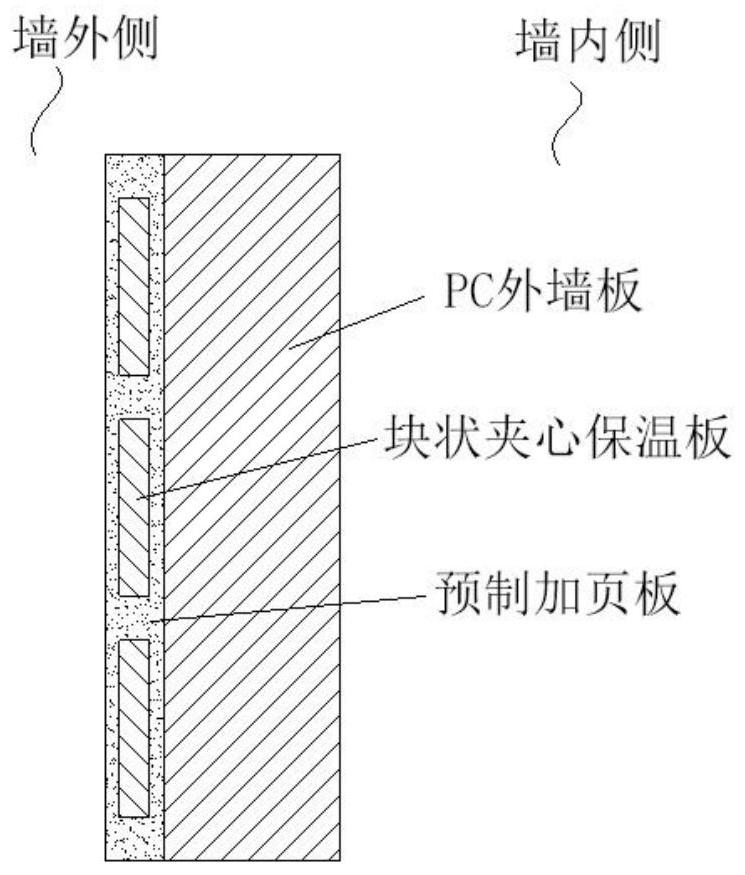

[0131] This embodiment relates to the PC thermal insulation integrated board in Embodiments 1 to 2.

[0132] like Figures 6 to 7 As shown, the present invention provides a PC thermal insulation integrated board, which includes a thermal insulation board 101 , several anchoring elements 102 , a wall board 103 and several steel bars 104 .

[0133] The insulation board 101 is a rectangular structure, and its parameters are: the dry density of the insulation board is 160-220kg / m 3 , compressive strength ≥ 0.30mPa, vertical plate tensile strength ≥ 0.25MPa, compressive elastic modulus ≥ 20000kPa, bending load ≥ 3000N, bending deformation ≥ 6mm, volume water absorption rate ≤ 6%, thermal conductivity less than or equal to 0.054W / m·K, softening coefficient ≥ 0.8, drying shrinkage rate ≤ 0.3%, and the combustion performance level is at least Class A.

[0134] In some of the embodiments, in order to improve the strength of the thermal insulation board 101 , the thermal insulation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com