Carbon black colored polyethylene glycol terephthalate color master batch and preparation method thereof

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of polymer material preparation, can solve the problem of easy generation of static electricity, poor dispersion effect of carbon black, polyethylene terephthalate, etc. Problems such as poor mechanical effect of esters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

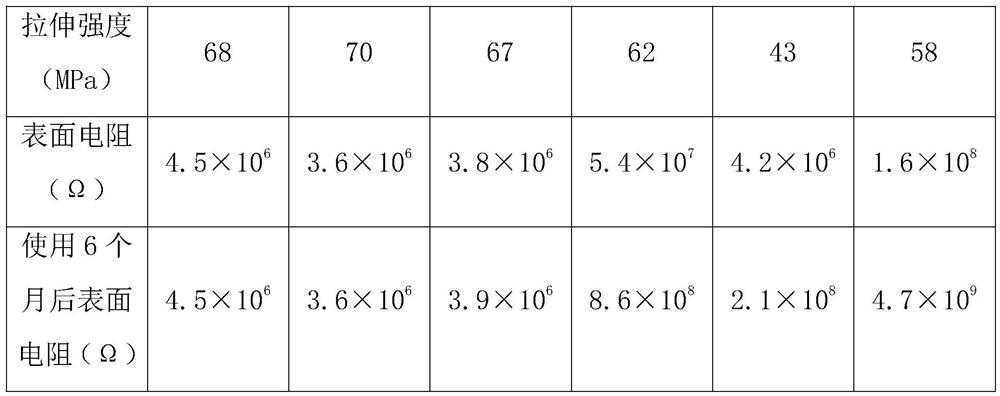

Embodiment 1

[0027]A carbon black colored polyethylene terephthalate masterbatch, including the following weight of raw materials: modified carbon black 6 parts, modified polyethylene terephthalate 40 parts, antistatic synergist 3 parts;

[0028] The carbon black colored polyethylene terephthalate masterbatch is made by the following steps:

[0029] The modified carbon black, modified polyethylene terephthalate, antistatic synergist dispersed in deionized water, adjust the pH of the reaction liquid to 10, at a speed of 300r / min, temperature of 70 ° C, stirred for 3h, add dibutyltin laurate, heated to a temperature of 140 ° C, continue to react for 5h, filter to remove the filtrate, the filter cake dried, and then add a twin screw extruder, at a speed of 60r / min, a zone temperature of 240 °C, a zone of 250 °C, Under the condition that the temperature of the third zone is 265 °C, the temperature of the fourth zone is 250 °C, and the temperature of the machine head is 250 °C, the masterbatch ...

Embodiment 2

[0038] A masterbatch of carbon black colored polyethylene terephthalate, including the following weight raw materials: 7 parts of modified carbon black, 45 parts of modified polyethylene terephthalate, 4 parts of antistatic synergist;

[0039] The carbon black colored polyethylene terephthalate masterbatch is made by the following steps:

[0040] The modified carbon black, modified polyethylene terephthalate glycol, antistatic synergist dispersed in deionized water, adjust the pH of the reaction liquid of 10, at a speed of 500r / min, temperature of 75 ° C, stirred for 4h, add dibutyltin dilaurate, heated to a temperature of 145 ° C, continue to react for 6h, filter to remove the filtrate, the filter cake dried, and then add a twin screw extruder, at a speed of 60r / min, a zone temperature of 245 ° C, a zone of 255 ° C, a temperature of 255 ° C, Under the conditions of 270 °C temperature of the third zone, 255 °C temperature of the fourth zone and 250 °C of the machine head, the ...

Embodiment 3

[0049] A carbon black colored polyethylene terephthalate masterbatch, including the following weight of raw materials: modified carbon black 8 parts, modified polyethylene terephthalate 50 parts, antistatic synergist 5 parts;

[0050] The carbon black colored polyethylene terephthalate masterbatch is made by the following steps:

[0051] The modified carbon black, modified polyethylene terephthalate, antistatic synergist dispersed in deionized water, adjust the pH of the reaction liquid to 11, at a speed of 500r / min, temperature of 80 ° C, stirred for 5h, add dibutyltin dilaurate, heated to a temperature of 150 ° C, continue to react for 7h, filter to remove the filtrate, the filter cake dried, and then add a twin screw extruder, at a speed of 90r / min, a zone temperature of 250 °C, a zone of 260 °C, Under the conditions of 275 °C temperature of the third zone, 260 °C temperature of the fourth zone and 250 °C of the machine head, the master grain of carbon black colored polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com