Descaling wheel for cement bin

A cement silo and wheel body technology, which is applied in the field of cement silo descaling wheels, can solve the problems of difficult removal of cement scale, damage to the cement silo body, and heavy workload of descaling, achieving high descaling efficiency and long service life , Improve the effect of descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

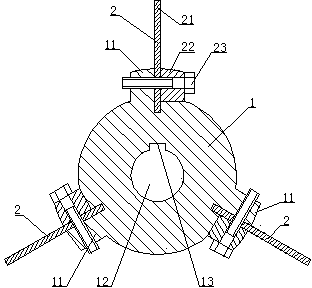

[0007] see figure 1 , the present invention comprises a wheel body 1 and three descaling assemblies 2 uniformly distributed in the circumferential direction, the wheel body 1 is provided with three protrusions 11 uniformly distributed in the circumferential direction, and an inner hole 12 and Keyway 13, described each descaling assembly 2 comprises spring steel sheet 21, pressing block 22 and screw 23, one end of described spring steel sheet 21 is inserted in the groove of wheel body 1, and described spring steel sheet 21 adopts pressing Block 22 and screw 23 are compressed on the wheel body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com