Composite fabric as well as preparation method and application thereof

A composite fabric and fabric technology, applied in the textile field, can solve the problems of poor tear resistance and inability to meet the needs of special environments, and achieve the effects of improving antibacterial and anti-mite, reducing the possibility of coil breakage and detachment, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

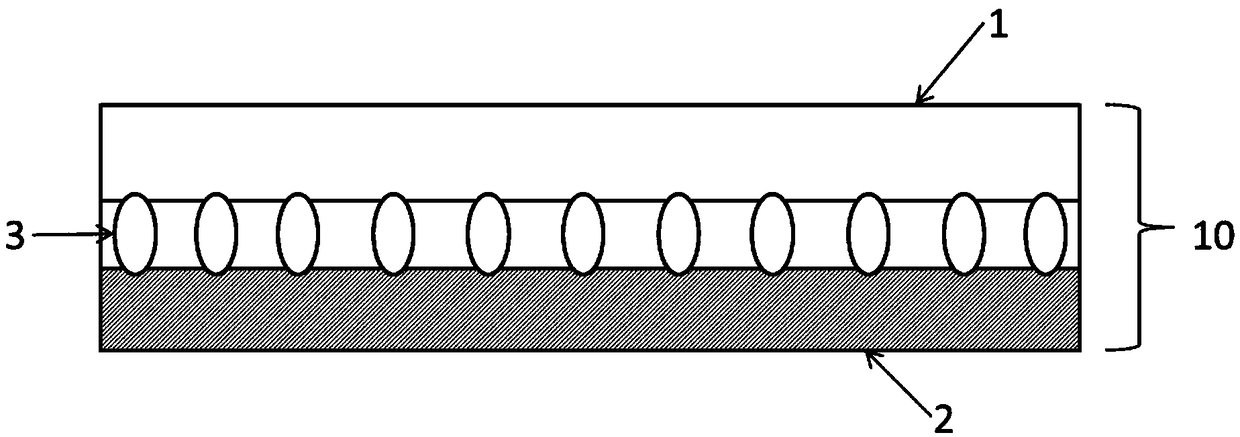

Method used

Image

Examples

Embodiment 1

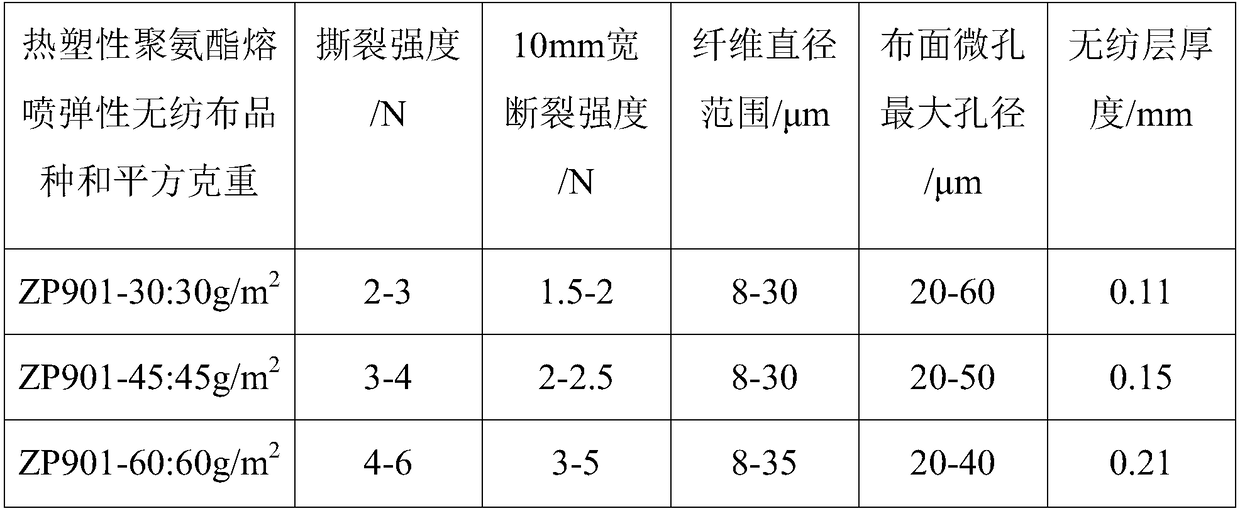

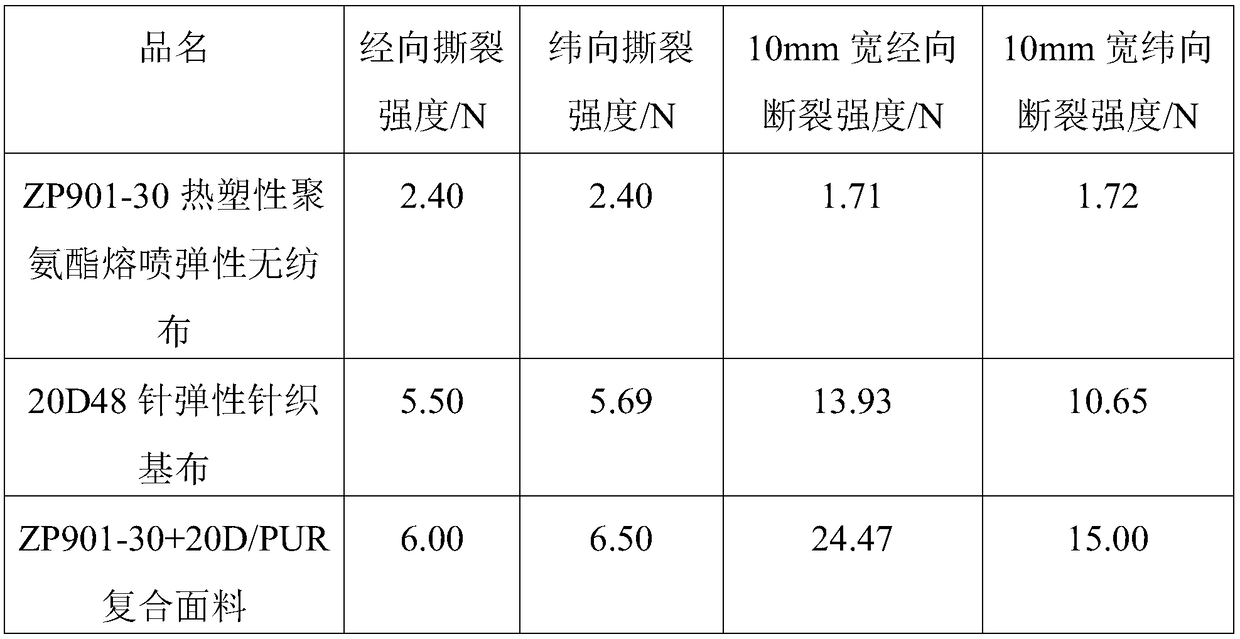

[0087] Thermoplastic polyurethane melt-blown elastic non-woven fabric layer: 30g / m is selected for use in this embodiment 2 The thermoplastic polyurethane melt-blown elastic non-woven fabric (ZP901-30) is used to produce anti-drilling fleece fabrics. The thermoplastic polyurethane melt-blown elastic non-woven fabric has a thickness of 0.11 mm and a fiber diameter of 8-30 μm. Test the warp and weft tear strength and breaking strength of the non-woven fabric layer, using a fabric breaking strength tester, model TH-8203S, manufacturer Suzhou Tuobo Machinery Equipment Co., Ltd., see Table 2 for the results, using a maximum magnification of 1000 Using a magnification electron microscope to measure the diameters of multiple micropores on the cloth surface, it can be seen that the maximum pore diameter between fibers is in the range of 20-60 μm.

[0088] Elastic knitted base fabric (20D plain weave): Use polyester low elastic yarn (DTY) 20D / 24F as the raw material to weave on a sing...

Embodiment 2

[0101] Thermoplastic polyurethane melt-blown elastic non-woven fabric layer: the present embodiment selects the same 30g / m described in embodiment 1 2 The thermoplastic polyurethane melt-blown elastic non-woven fabric is used to produce composite swimwear fabrics.

[0102] Elastic knitted base fabric: Use polyester low elastic yarn (DTY) 20D / 24F as raw material to weave on a 32-needle warp knitting machine to obtain elastic knitted base fabric, and use heavy warp weave to weave 1-3 / 2-0 / / fabric , the door width of the upper machine is 180 inches and the double width (the single width of the upper machine is 228.6cm), and the weft density of the upper machine is 21 turns / cm.

[0103] The gray cloth after getting off the machine needs to be dyed by overflow and then shaped. When shaping, you can add softener and water-repellent agent in the rolling groove for water-repellent and soft treatment. The width of the shaped door is 153-154cm, and the warp and weft density is (17-18) x...

Embodiment 3

[0109] Thermoplastic polyurethane melt-blown elastic non-woven fabric layer: the present embodiment selects the same 30g / m described in embodiment 1 2 The thermoplastic polyurethane meltblown elastic nonwoven fabric is used to produce sunscreen outdoor sports fabrics.

[0110] Elastic knitted base fabric: the elastic knitted base fabric described in Example 1 is used in this embodiment.

[0111] Composite: except coating amount, all the other are identical with the method of embodiment 1. Coating amount 8.5g / m 2 .

[0112] Low-temperature dyeing and sunscreen treatment: Dye the composite fabric with low-temperature disperse dyes under slightly acidic conditions at 110°C. After low-temperature dyeing, add 15-30g / l ultraviolet absorber (SUNLIFE LPS-980NZ of Rihua Company) in the rolling groove when drying and setting in the follow-up setting machine, the padding rate is 75-90%, and the air-drying setting temperature is at 120 -130°C. After this treatment, the protective eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square gram weight | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com