Polyurethane composition for making solid footballs as well as preparation method and application of polyurethane composition

A technology of polyurethane and composition, applied in the field of polyurethane composition for making solid soccer ball and its preparation, can solve the problems of poor elasticity and wear resistance, inconvenient use, hard hand feeling, etc., and achieve good elasticity and wear resistance, service life Long, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

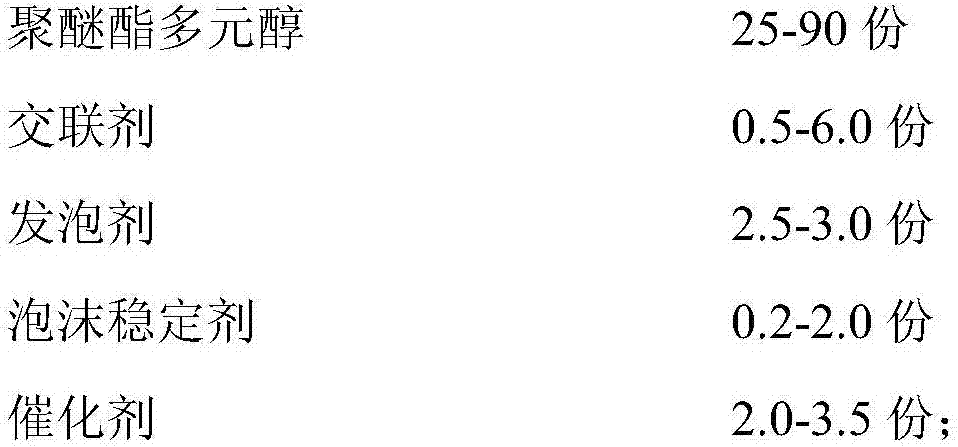

[0030] The raw materials of component A are:

[0031]

[0032]

[0033] The raw materials of component B are:

[0034]

[0035] Its preparation method is as follows:

[0036] (1) Preparation of component A material: First, put polyether ester polyol into the reaction kettle and stir, then add crosslinking agent, catalyst, foam stabilizer and foaming agent in sequence, at room temperature, the speed is 80 rpm / minute, stirring for 1 hour, sampling for detection, and meeting the various detection indicators, that is, the qualified product of component A, which is discharged from the reaction kettle and loaded into barrels for storage.

[0037] (2) Preparation of component B material: Put the polyester polyol into the reaction kettle at room temperature, stir and heat up to 90°C, dehydrate under vacuum conditions (vacuum degree≤-0.098MPa) (dehydrate to moisture content≤0.05%) Gas for 2.5 hours, lower the temperature to 60°C, add phosphoric acid, pure MDI, carbodiimide...

Embodiment 2

[0040] The raw materials of component A are:

[0041]

[0042] The raw materials of component B are:

[0043]

[0044]

[0045] Its preparation method is as follows:

[0046] (1) Preparation of component A material: First, put polyether ester polyol into the reaction kettle and stir, then add crosslinking agent, catalyst, foam stabilizer and foaming agent in sequence, at room temperature, the speed is 80 rpm / minute, stirring for 1.5 hours, taking samples for testing, and meeting the various testing indicators, that is, the qualified product of component A is obtained, and the material is discharged from the reactor and stored in barrels.

[0047] (2) Preparation of component B material: Put the polyester polyol into the reaction kettle at room temperature, stir and heat up to 95°C, and dehydrate under vacuum conditions (vacuum degree≤-0.098MPa) (dehydration to moisture content≤0.05%) Gas for 2.5 hours, lower the temperature to 60°C, add phosphoric acid and isocyan...

Embodiment 3

[0050] The raw materials of component A are:

[0051]

[0052] The raw materials of component B are:

[0053]

[0054] Its preparation method is as follows:

[0055] (1) Preparation of component A material: first, put polyether ester polyol into the reaction kettle and stir, then add crosslinking agent, catalyst, foam stabilizer and foaming agent in sequence, under normal temperature conditions, the speed is 60 rpm / minute, stirring for 2.0 hours, sampling for detection, meeting the various detection indicators, that is, the qualified product of component A, which is discharged from the reactor and stored in barrels.

[0056] (2) Preparation of component B material: Put the polyester polyol into the reaction kettle at room temperature, stir and heat up to 100°C, and dehydrate under vacuum conditions (vacuum degree≤-0.098MPa) (dehydration to moisture content≤0.05%) Gas for 2.5 hours, lower the temperature to 60°C, add phosphoric acid and isocyanate at the same time, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com