Blade type anti-corrosion anti-sticky cloth guide roller

A blade-type, cloth guide roller technology, applied in the printing and dyeing machinery and textile fields, can solve the problems of high cost of use, non-detachable connection, non-replacement, etc., achieve low cost of use, improve anti-corrosion performance, and ensure quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

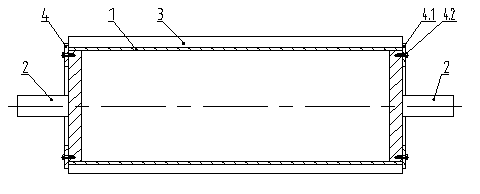

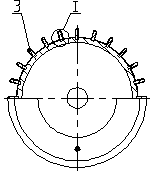

[0022] The blade-type anti-corrosion and anti-sticking cloth guide roller shown in the accompanying drawings includes a roller 1, a support shaft 2 and a blade 3 coaxially fixedly connected to both ends of the roller 1; the outer surface of the roller 1 is provided with several longitudinal The groove 1.2, the blade 3 is detachably connected with the roller 1, in this embodiment, the two ends of the roller 1 are provided with fastening structures 4 to fix the blade 3 in the longitudinal groove 1.2 on the outer surface of the roller 1; The structure 4 includes a ring plate 4.1 and fastening bolts 4.2; the fastening bolts 4.2 fasten the ring plate 4.1 to the end of the roller 1; the ring plates 4.1 at both ends clamp the blade 3 in the middle.

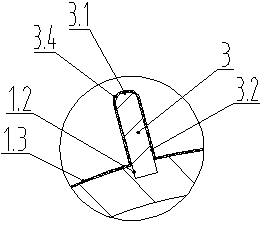

[0023] The intersection of the outer end surface 3.1 of the blade 3 and the two side surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com