engine driven work machine

A technology for engine-driven and working machines, which is applied in the direction of engine components, combustion engines, machines/engines, etc., which can solve the problems of limited use areas, obstacles to miniaturization of engine-driven working machines, difficulty in use, etc., and achieve the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

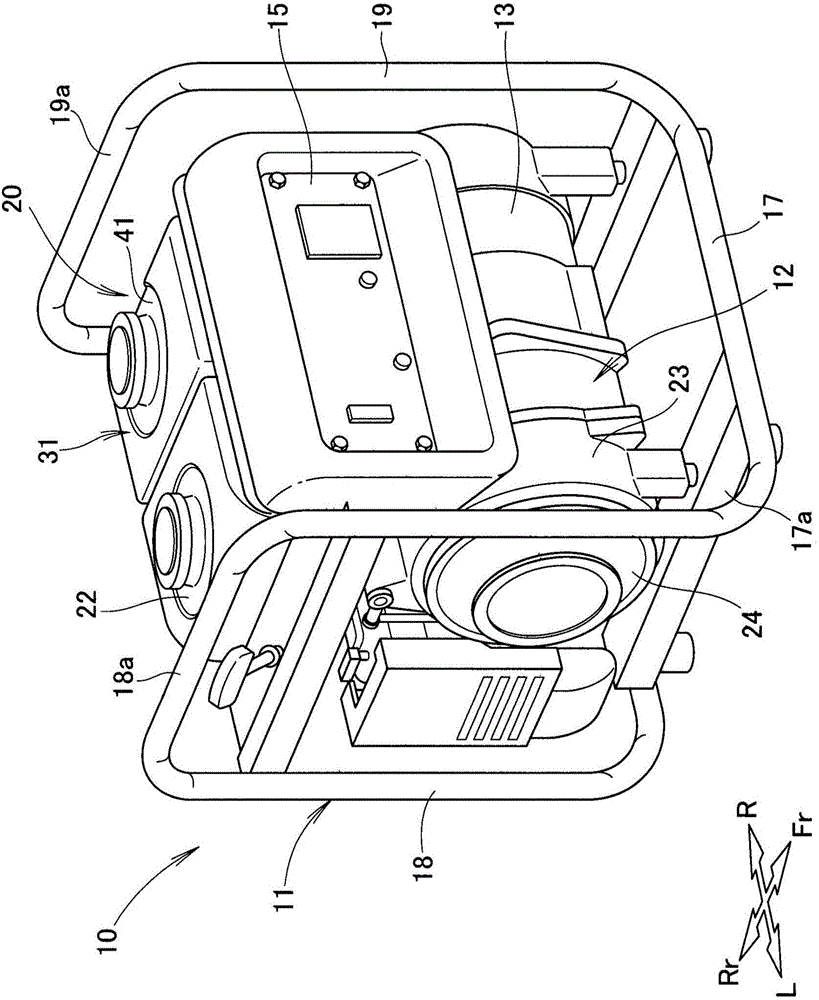

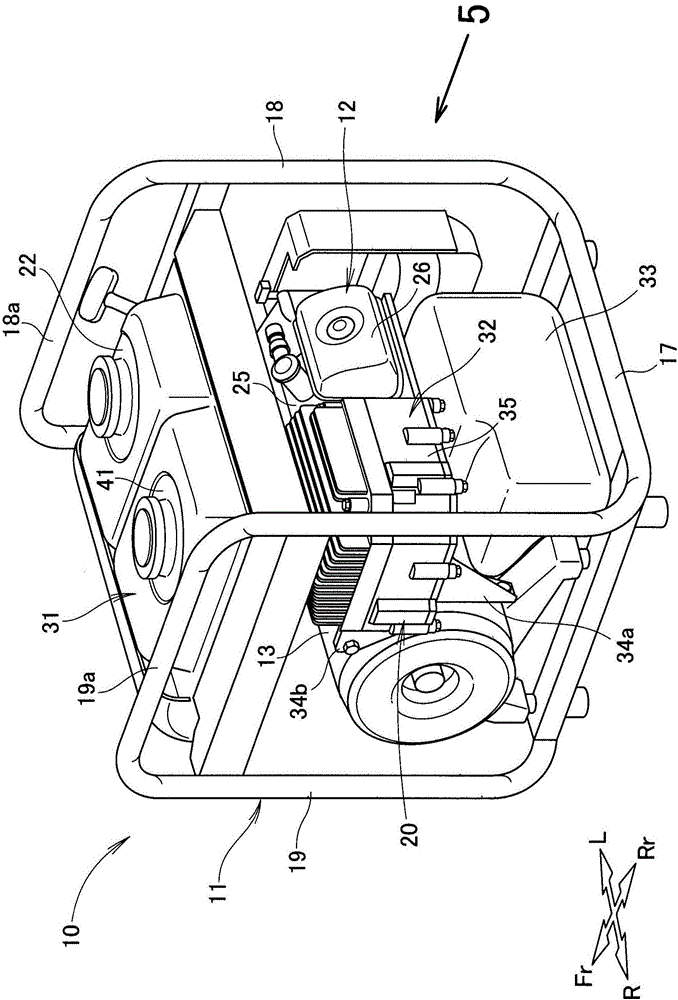

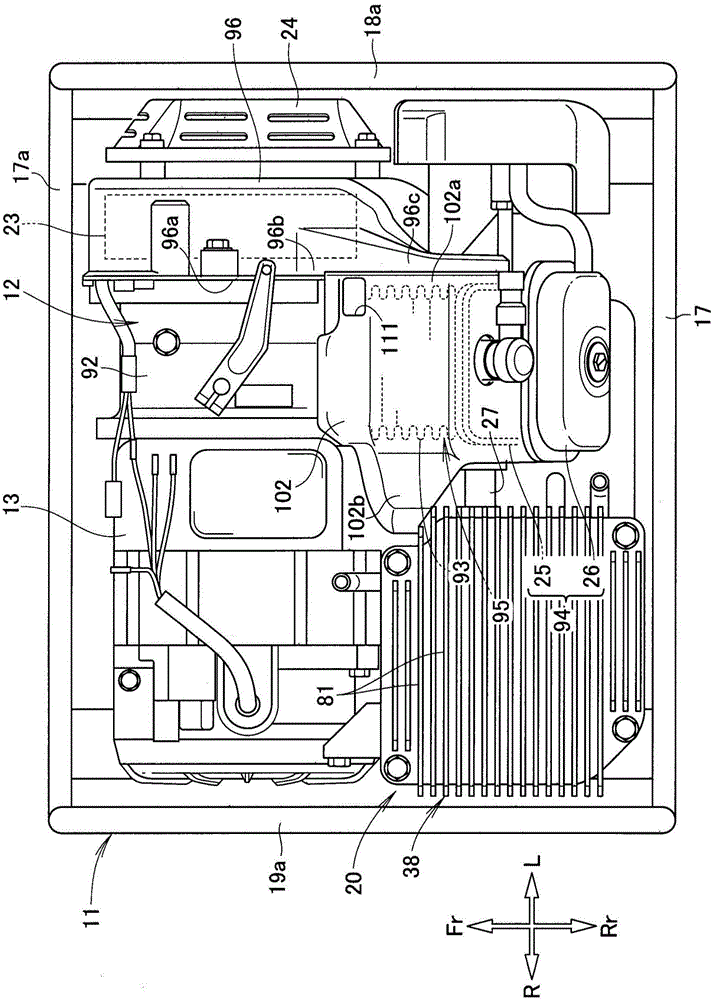

[0033] The engine-driven working machine 10 according to the embodiment will be described.

[0034] In addition, in order to easily understand the structure of the engine-driven work machine 10, in Figure 4 , Figure 5 The illustration of the heating mantle unit 101 and the cooling mantle 104 is omitted in FIG.

[0035] Such as figure 1 , figure 2 As shown, the engine-driven working machine 10 is an engine-driven generator with the following parts: a frame 11, which forms the outer frame of the engine-driven working machine 10; an engine 12, which is arranged at the front lower left part of the frame 11; 13, which is integrally arranged on the engine 12; the water generating device 20, which is arranged adjacent to the generator 13 and the engine 12; and the operation panel 15, which is arranged on the fuel tank 22 of the engine 12 and the raw water tank of the water generating device 20 41 ahead.

[0036] The frame 11 has: a base 17 that supports the engine 12, the gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com