vehicle control system

A vehicle control system and control circuit technology, applied to vehicle components, transmission control, brakes, etc., can solve the problems of inability to ensure the safety of the wire control system and the inability to quickly stop the mechanical operation of the wire control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

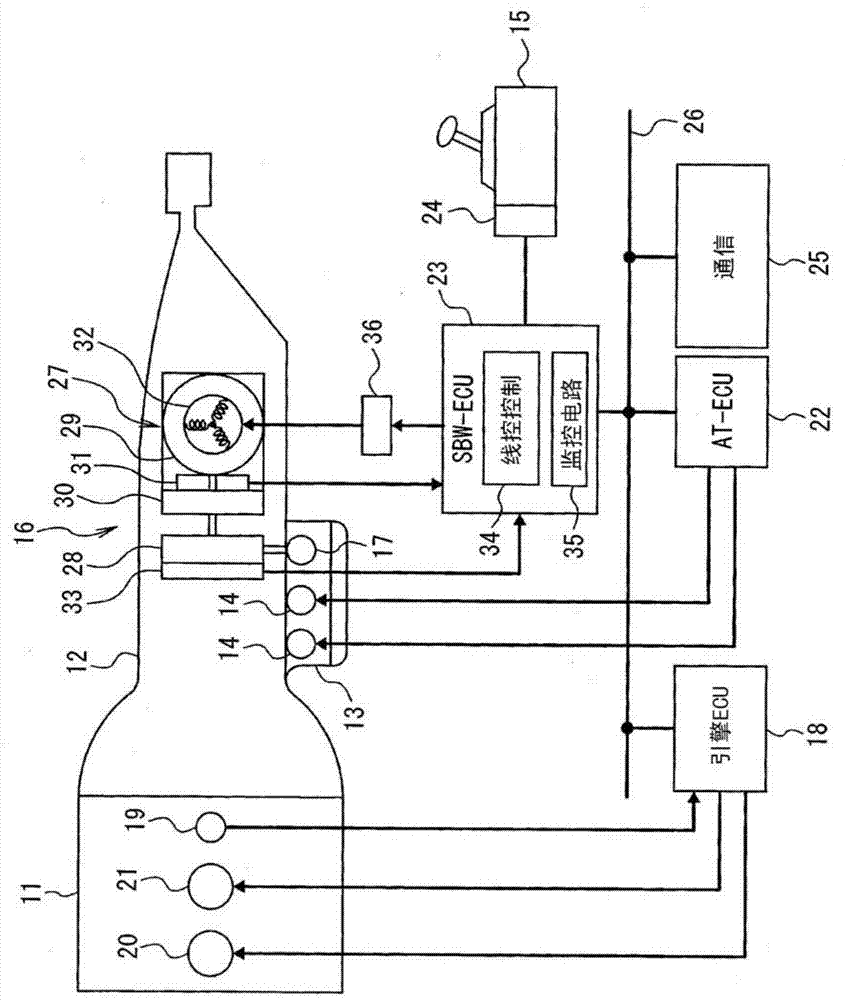

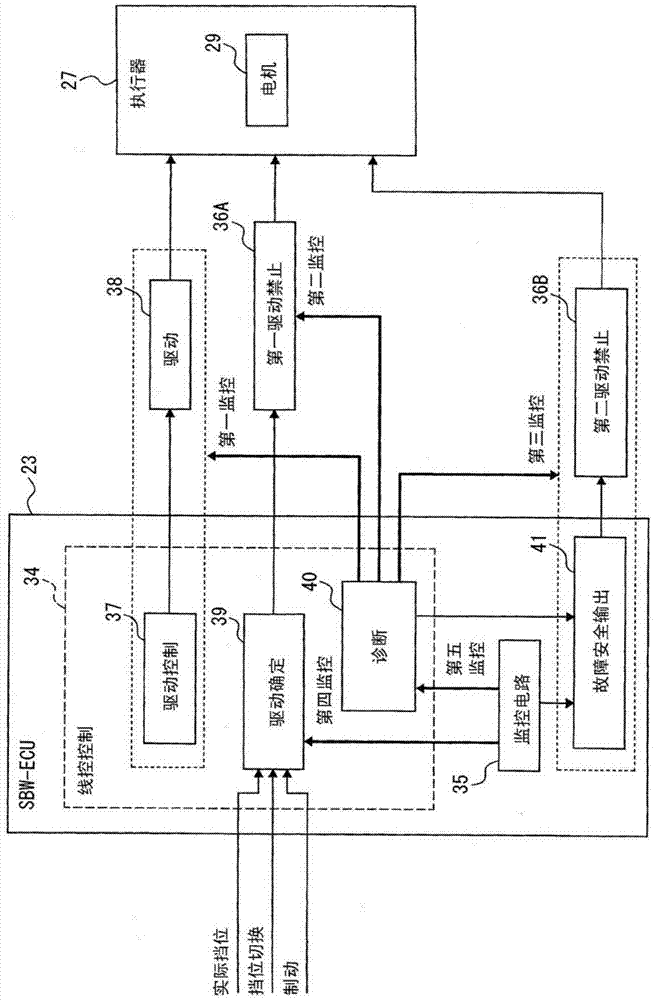

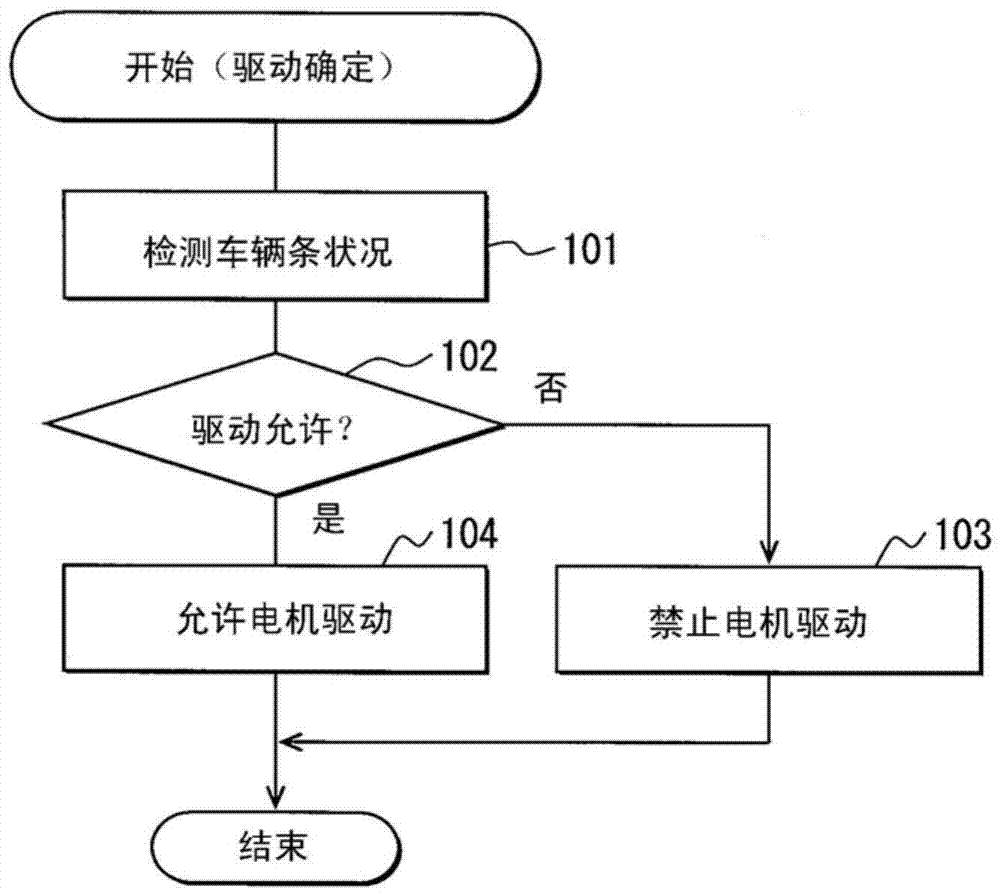

[0015] will refer to Figure 1 to Figure 5 The first embodiment will be described. First, refer to figure 1 A schematic configuration of an automatic transmission control system for a vehicle will be described.

[0016] An input shaft of the automatic transmission 12 is coupled to an output shaft (crankshaft) of the engine 11 . The automatic transmission 12 has a transmission gear mechanism (not shown), a friction engagement device (not shown), a hydraulic control unit 13 and the like. The friction engagement device switches the combination (speed ratio) of the power transmission gears among the plurality of wheels constituting the transmission gear mechanism. The hydraulic control unit 13 hydraulically switches the operating state of the friction engagement device. The hydraulic control unit 13 has a hydraulic control valve 14 and a manual valve 17 . The hydraulic pressure control valve 14 controls hydraulic pressure supplied to frictional engagement members such as clut...

no. 2 example

[0085] will refer to Figure 6 The second embodiment will be described. Substantially the same parts as those in the first embodiment are designated with the same reference numerals to simplify description, and only different parts will be described below.

[0086] According to the second embodiment, as Figure 6 As shown in , a control circuit other than the drive-by-wire control circuit 34 of the SBW-ECU 23 is configured to have the function of the drive determination section 39 . In particular, the shift control circuit 44 of the AT-ECU 22 has the function of the drive determination unit 39 . The shift control circuit 44 of the AT-ECU 22 determines permission and prohibition of driving the electric motor 29 by the drive determination unit 39 . When it is determined that the driving of the electric motor 29 is prohibited, that is, when the driving of the electric motor 29 is not permitted, the driving of the electric motor 29 is prohibited by the first drive prohibiting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com