Antifreeze check valves for liquid transfer lines

A technology for conveying pipelines and check valves, applied in the field of antifreeze check valves, can solve problems such as affecting production efficiency, and achieve the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

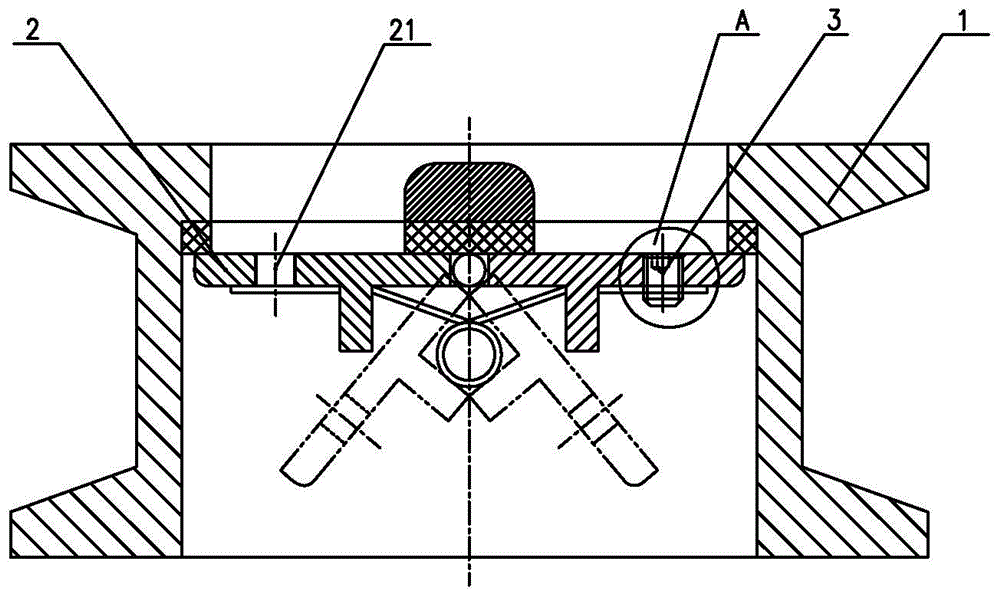

[0028] refer to figure 1 , Figure 4 As shown, the plugging device 3 is a bolt compatible with the thread of the damping hole 21, and when the damping hole needs to be blocked, the check valve is removed, and the blocking hole is blocked with the plugging device.

Embodiment 2

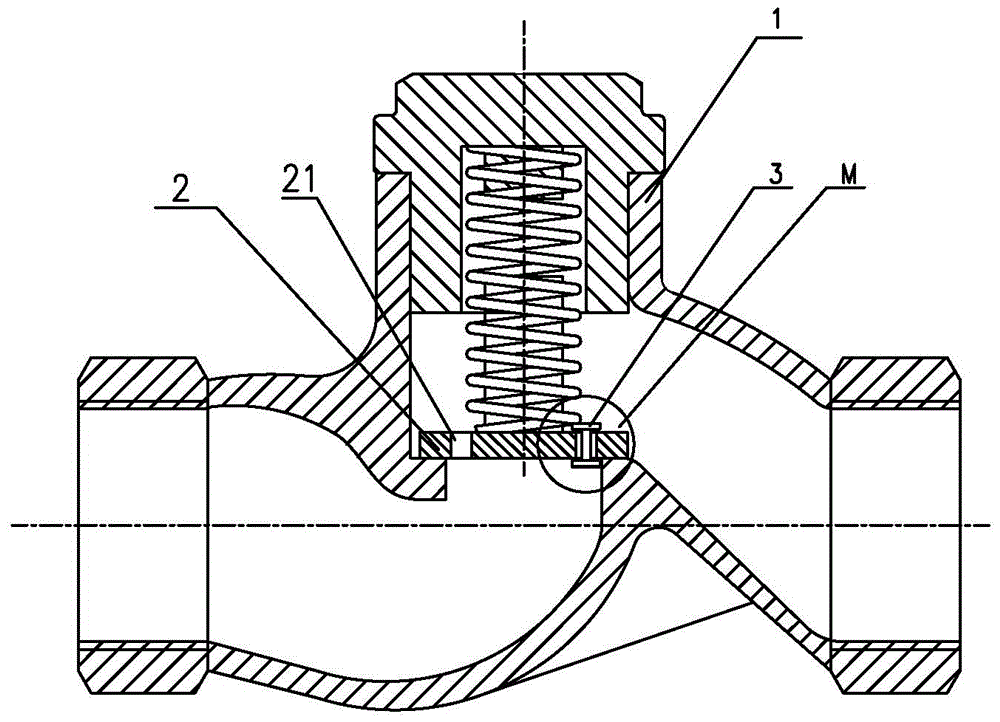

[0030] refer to figure 2 , Figure 5 As shown, the plugging device 3 is a "I" structural member made of a material with a volume expansion coefficient greater than 50%. The middle part of the plugging device 3 is stuck in the damping hole 21, and the diameter of both ends is larger than the damping hole. 21 diameter, so that the member cannot escape from the damping hole. Due to the volume shrinkage at low temperature, the diameter of the middle part will be smaller than the diameter of the damping hole. There is an obvious gap between the damping hole and the structure, and the damping hole is in a connected state. When the diameter of the middle part of the structure is equivalent to the diameter of the damping hole, there is basically no gap between the plugging structure and the damping hole, and the damping hole is blocked. When the temperature is higher, the volume expansion of the plugging structure is greater, and the damping hole is completely blocked. The structur...

Embodiment 3

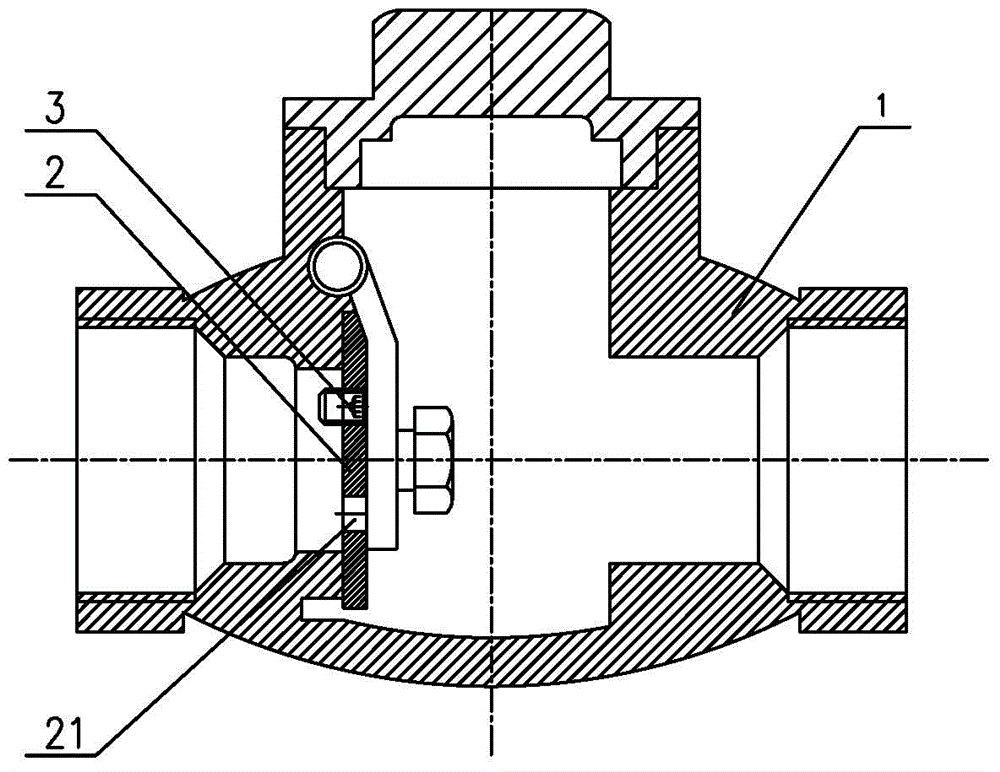

[0032] refer to Figure 6 , 7 As shown, the plugging device 3 includes a cover piece 311 and a rotating shaft 312. The cover piece 31 is assembled on the valve flap 2 through the rotating shaft 32. The cover piece 31 can rotate relative to the valve flap 2, and the different orientations of the cover piece 31 are rotated to realize alignment. The closure and communication of the damping hole 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com