Cooling and ventilation system for floating wind generating set

A technology for wind turbines and ventilation systems, which is applied to ventilation systems, wind turbines, and the configuration of installing/supporting wind turbines, etc., can solve the problems of insufficient cooling effect and high manufacturing costs, prevent corrosive damage, and improve usage. Longevity, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

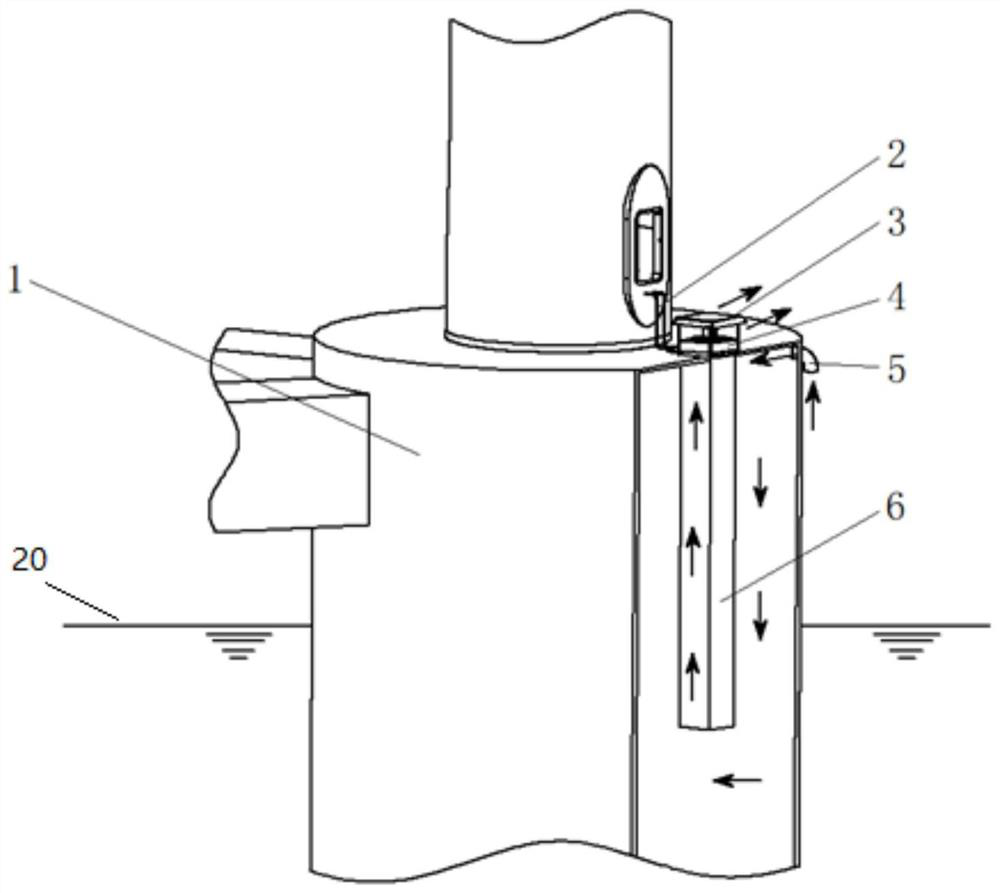

[0036] Such as figure 1 and figure 2 As shown, the present invention provides a cooling and ventilation system for floating wind turbines, including:

[0037] The air cooler 4 is located on the outer wall of the floating foundation 1 of the floating wind power generating set, and is located above the water surface 20°;

[0038] The air inlet pipe 5 is arranged on the outer wall of the floating foundation 1 and is located above the water surface 20, and is used to introduce the outside air into the inside of the floating foundation 1;

[0039] The air guide pipe 6 is located inside the floating foundation 1, the upper port of the air guide pipe 6 communicates with the air cooler 4, and the lower port is located below the water surface 20;

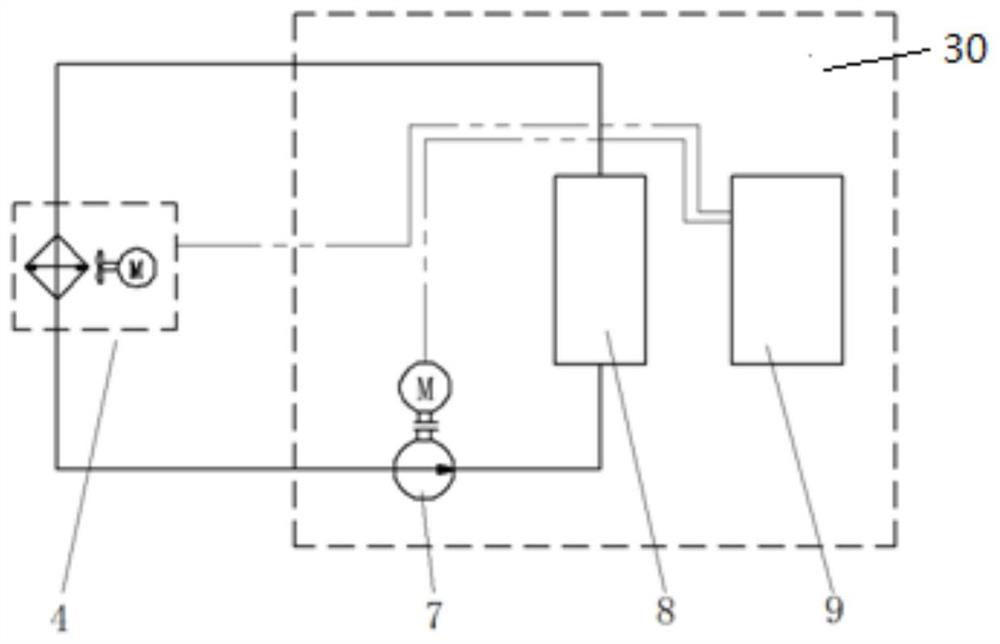

[0040] The pipeline 2 is connected in series with the component to be cooled 8, the water pump 7 and the air cooler 4 in sequence to form a loop for the circulation of the cooling liquid; and

[0041] The controller 9 is electrically con...

Embodiment 2

[0051] When maintaining the equipment inside the floating foundation 1, the staff will enter the inside of the floating foundation 1 to perform operations. Because the embodiment 1 is provided with an air duct 6 inside the floating foundation 1, and the air duct air duct The area of the air duct is more than 1 square meter, so the staff may stumble and fall into the air duct during operation, which poses a safety hazard. At the same time, the end of the air inlet pipe 5 connected to the air inlet is bent downward, although it can prevent the falling objects from entering the inside of the floating foundation and cause damage, but it cannot prevent such accidents as birds flying into this type of accident, and there is also a safety hazard. Hidden danger.

[0052] In order to solve the above-mentioned technical problems, further optimize on the basis of embodiment 1, adopt the following technical scheme, the cooling and ventilation system also includes a first protective net ...

Embodiment 3

[0055] In Example 1, such as figure 1 As shown, the air cooler 4 is installed on the top platform of the floating foundation 1. When it rains, the rainwater will directly pour into the air cooler 4, which will affect the service life of the air cooler 4, such as Short circuit fault.

[0056] In order to solve the above technical problems, further optimization on the basis of Example 1, the following technical scheme is adopted, a rain cover is set above the air cooler, the shape, size and material of the rain cover are not limited, and the rain cover can completely cover Air coolers so that rainwater cannot drip onto the air coolers. The installation method of the rain shield is not limited. In this embodiment, for example, riveting and screw connection can be used to provide better connection strength and resist the vibration caused by the turbulence of the sea surface.

[0057] Using the rain cover can prevent the rainwater from dripping on the air cooler and cause corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com