Inverted tooth gravel conveying pipe

A technology of conveying pipes and inverted teeth, which is applied in the field of conveying pipes, can solve problems such as backflow, and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

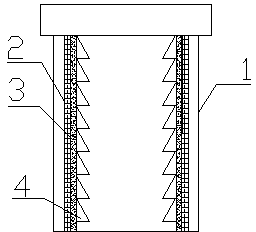

[0011] like figure 1 It is a schematic diagram of the structure of the present invention. The inverted-toothed gravel conveying pipe includes a pipe steel matrix 1, a metal alloy transition layer 2 and superhard material particles 3. The inner wall of the pipeline steel matrix 1 is provided with a metal alloy transition layer 2 and superhard material particles. 3. The metal barb 4 is fixed on the pipeline steel base 1, the tip of the metal barb 4 faces the direction of the delivery pipe outlet, and the metal barb 4 is a high manganese steel barb.

[0012] The pipeline steel matrix 1 is covered with metal barbs 4, and the metal barbs 4 are made of high manganese steel, which can ensure their wear resistance, and the tip orientation of the metal barbs 4 can prevent debris from flowing in from the opposite direction. The conveying pipe can prevent the debris flowing in the pipe from flowing backwards, thus making the dredging work more efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com