High-temperature-resistant reflective fabric

A technology of high temperature resistant and reflective cloth, which is applied in optics, optical components, instruments, etc., can solve the problems of poor use effect and easy falling off, and achieve the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

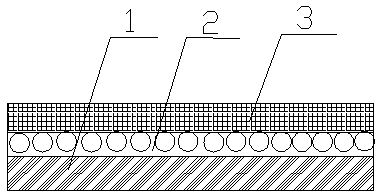

[0011] Such as figure 1 It is a structural schematic diagram of the present invention, a high temperature resistant reflective cloth, including a base layer 1 and a reflective layer 2, and also includes a high temperature resistant layer 3, the base layer 1 is provided with a reflective layer 2, and the reflective layer 2 is provided with a high temperature resistant layer 3. The reflective layer 2 is a glass bead reflective layer. The high temperature layer 3 is a high temperature resistant cloth.

[0012] The present invention is equipped with a high temperature resistant cloth on the reflective layer 2, which can effectively avoid the defect that the glass beads fall off due to the low anti-destructive ability under the irradiation of the sun, prolongs the service time of the reflective cloth, and has a simple structure and is easy to manufacture .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com