Improved air-adjusting door for circulating fluid bed boiler

A circulating fluidized bed, improved technology, applied in the direction of fluidized bed combustion equipment, combustion type, valve configuration, etc., to achieve the effect of improved working stability and stable air adjustment opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

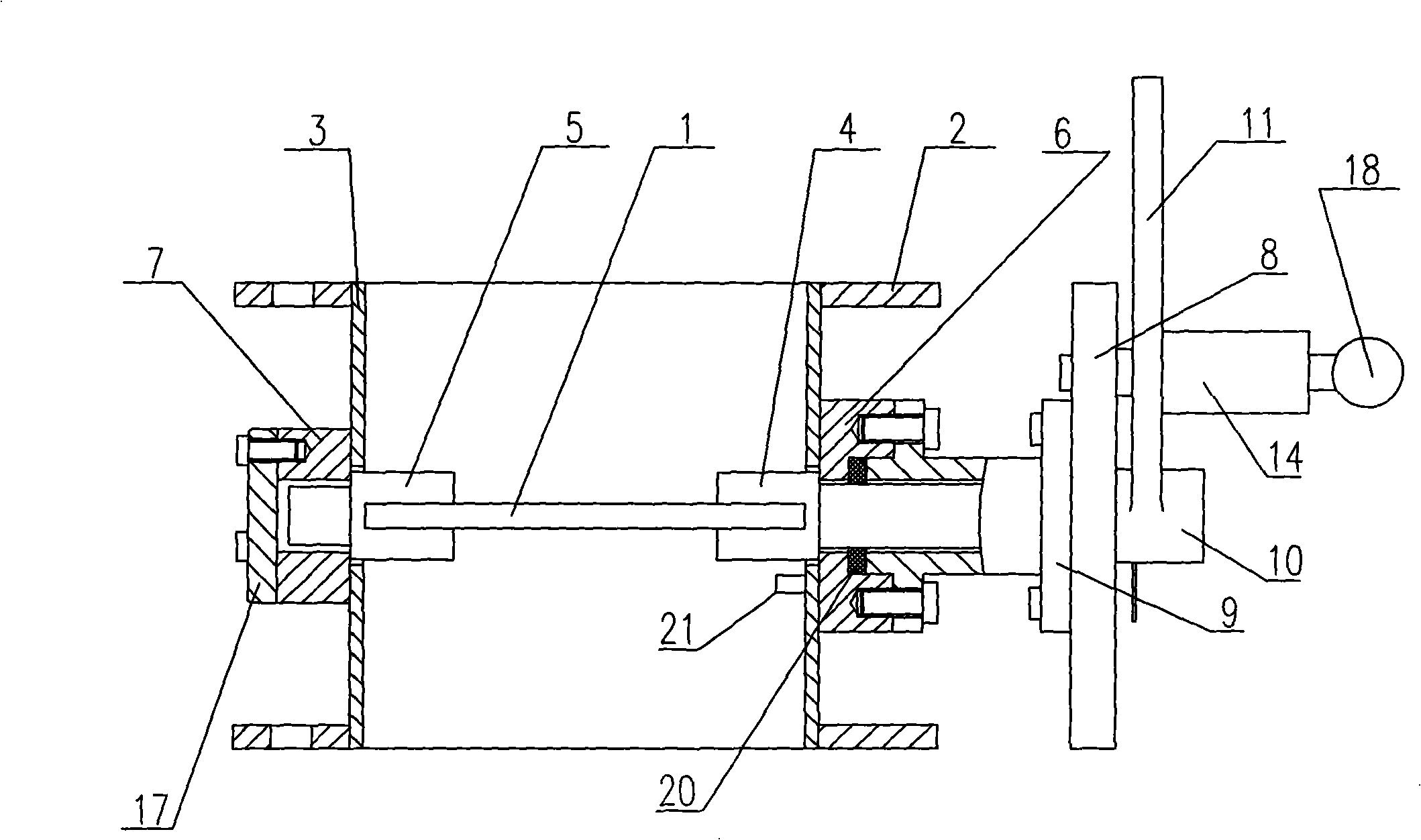

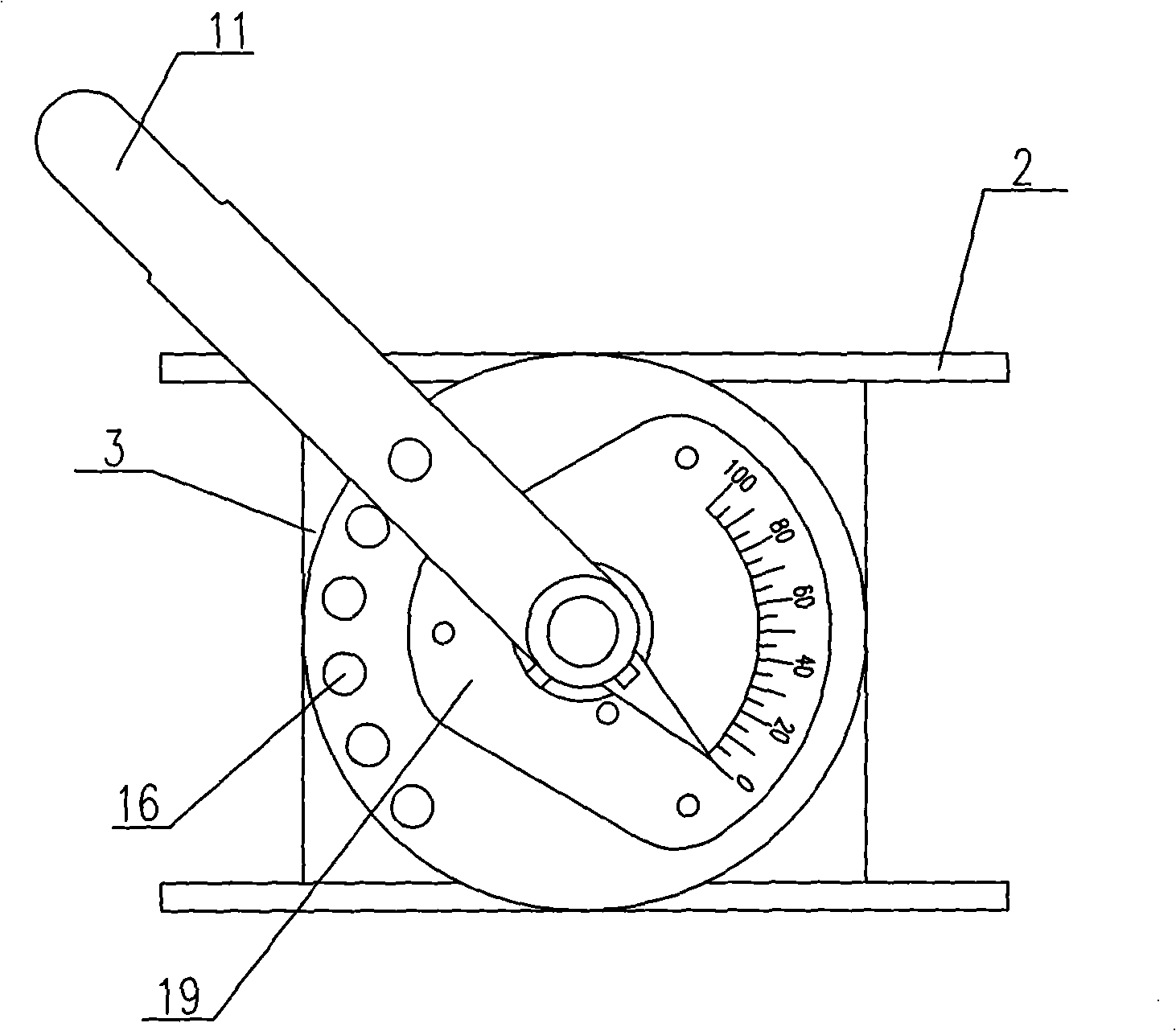

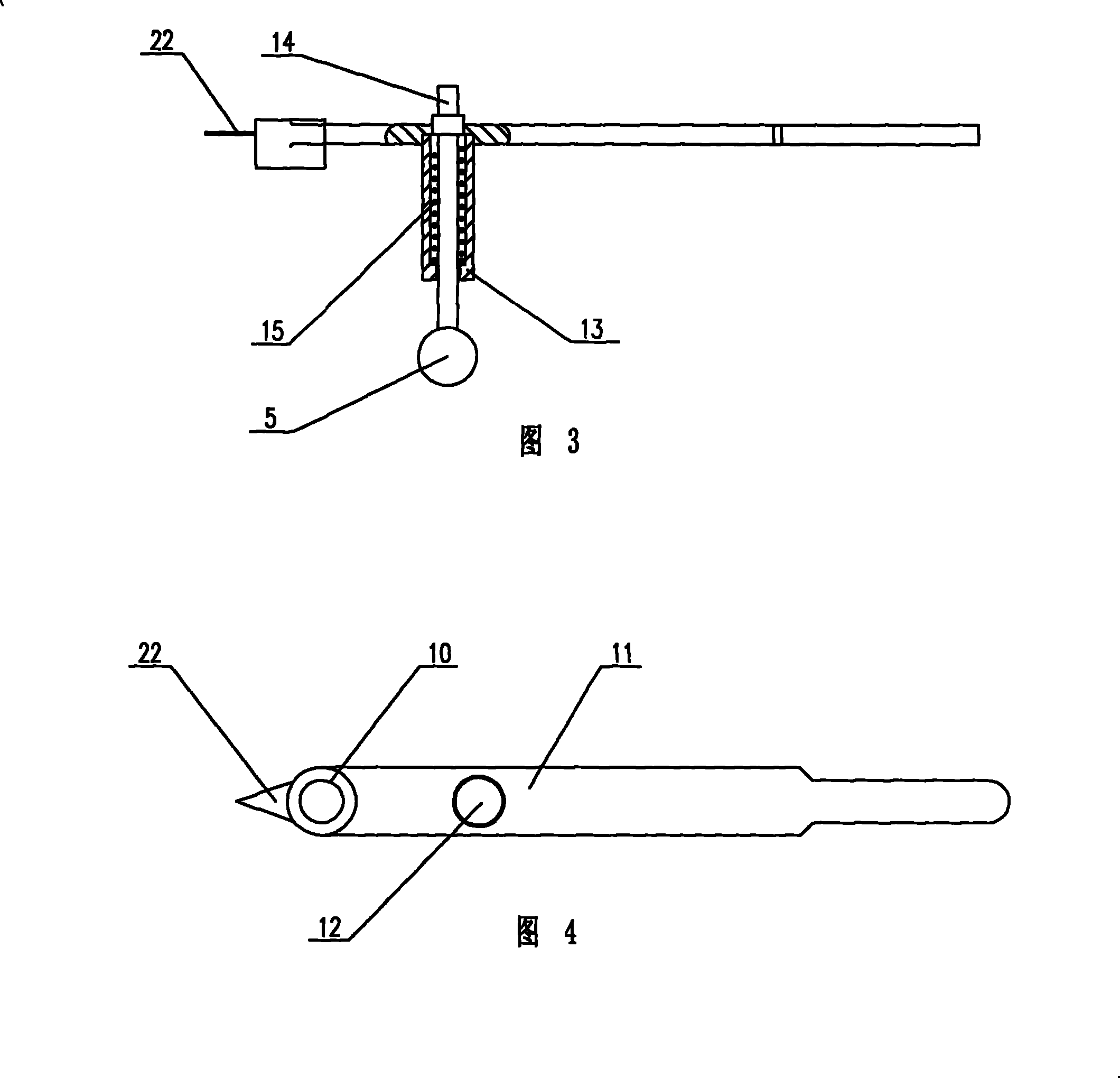

[0019] See figure 1 , figure 2 , image 3 , Figure 4 , the present invention includes a door panel 1, a flange 2, a cylinder body 3, a front connecting shaft 4, a rear connecting shaft 5, a front bearing seat 6, a rear bearing seat 7, a positioning plate 8, a connecting seat 9, and the door panel 1 is welded and connected to the front connecting shaft 4. The rear connecting shaft 5 and the end of the front connecting shaft 4 exposed to the cylinder body 3 are connected to the connecting sleeve 10, the connecting sleeve 10 is connected to the handle 11, the handle 11 has a mounting hole 12, and the spring seat 13 is set on the adjusting rod 14. A spring 15 is housed in the cavity surrounded by the rod 14 and the spring seat 13. The spring seat 13, the adjustment rod 14 and the spring 15 form a positioning device, which is set in the mounting hole 12. The positioning plate 8 is provided with a plurality of The positioning hole 16 and the adjusting rod 14 are exposed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com