Method for refined and directional solidification of titanium aluminium alloy slab surface structure

A technology of titanium-aluminum alloy and directional solidification, which is applied in the field of processing the surface structure of titanium-aluminum alloy slabs, can solve the problems that the directionally solidified columnar grain structure and equiaxed fine-grain composite structure cannot be formed, and avoid loose mixed oxidation The effect of film, meeting the requirements of high temperature creep and high temperature fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

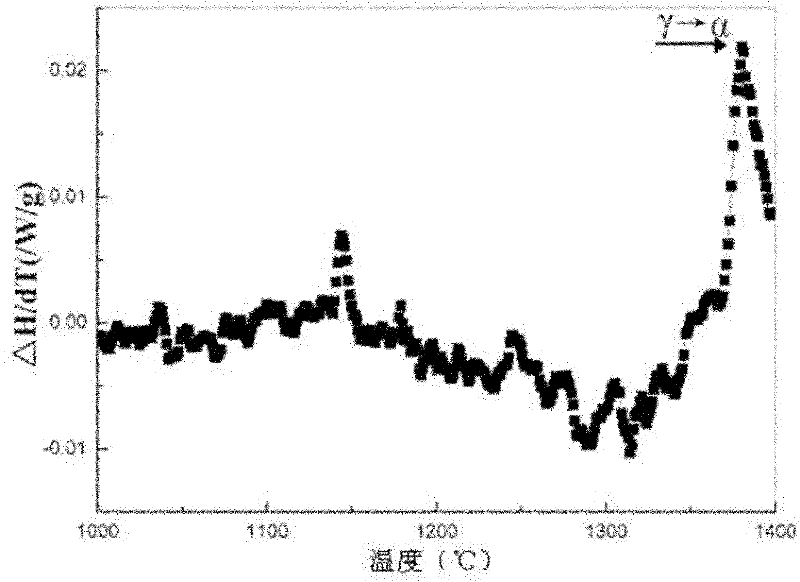

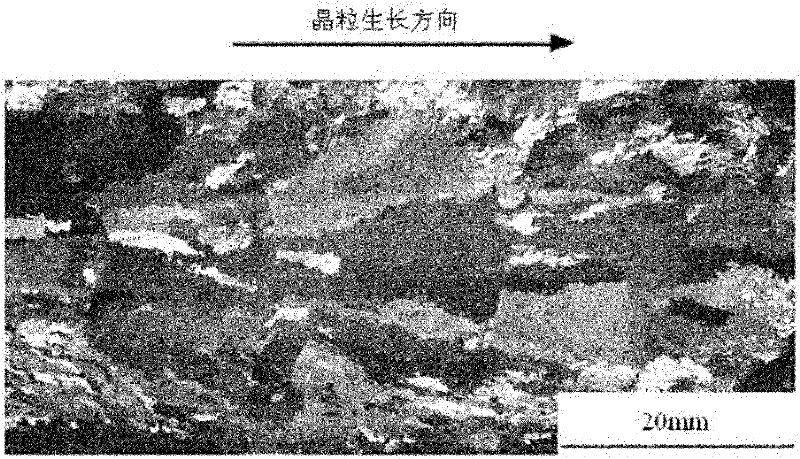

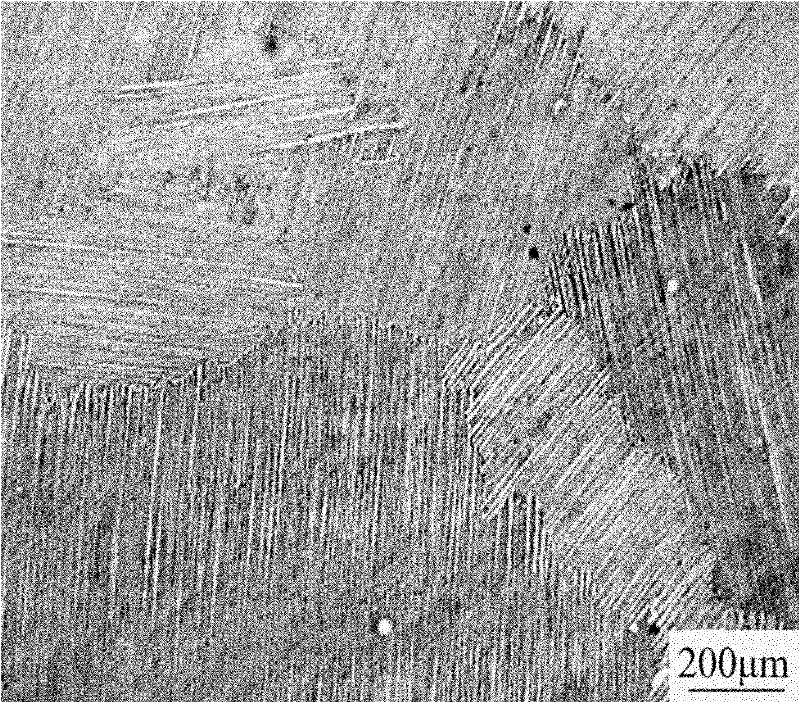

[0011] Specific Embodiment 1: A method for refining the surface structure of the directionally solidified titanium-aluminum alloy slab in this embodiment is carried out according to the following steps: 1. Test the temperature A at which the directionally solidified titanium-aluminum alloy slab transforms from the γ phase to the α phase ; 2. At room temperature, the titanium-aluminum alloy slab is subjected to surface plastic deformation by ball rolling, and the reduction is 0.1mm to 0.2mm; 3. The titanium-aluminum alloy slab sample after surface plastic deformation is placed in the Seal the quartz tube and evacuate the quartz tube to 1×10 -4 Pa~1×10 -3 Pa; 4. Put the quartz tube in step 3 in a heating furnace and heat it to a temperature 10°C to 20°C higher than temperature A and keep it for 10min to 20min, then take out the aluminum alloy slab from the quartz tube and put it into a temperature of 10°C Quenching in water at ~25°C to obtain a directionally solidified titanium...

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that: the reduction amount of the surface plastic deformation in step 2 is 0.12mm-0.18mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiment 1 in that: the reduction amount of the surface plastic deformation in step 2 is 0.15 mm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com