Portable electronic product, touch screen and touch screen preparation method

An electronic product, portable technology, applied in electrical digital data processing, instruments, digital data processing parts and other directions, can solve the problem of formation, and achieve the effect of eliminating height difference, ensuring the thickness of the ink layer, and ensuring the color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

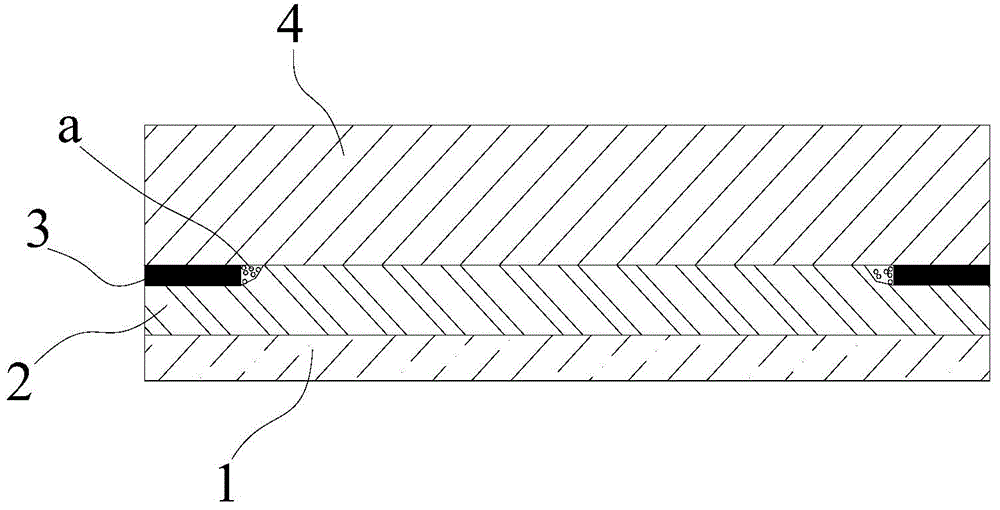

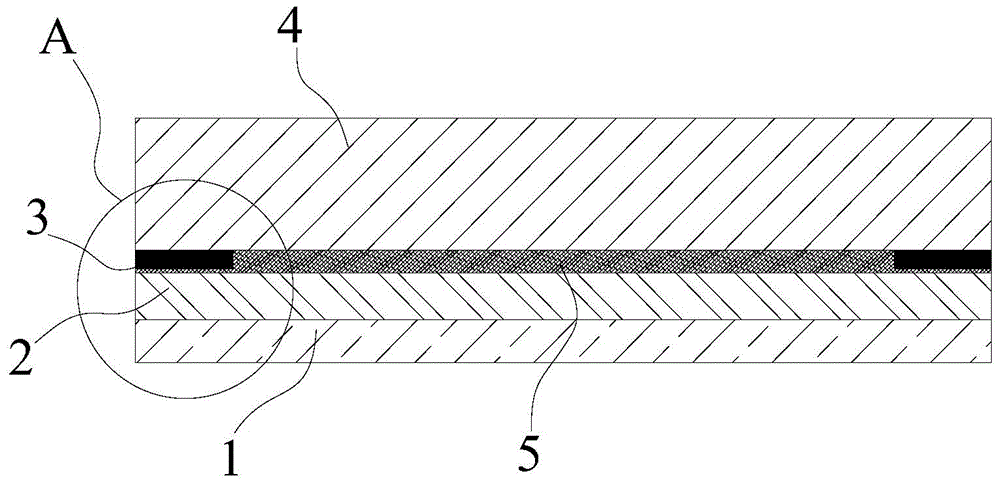

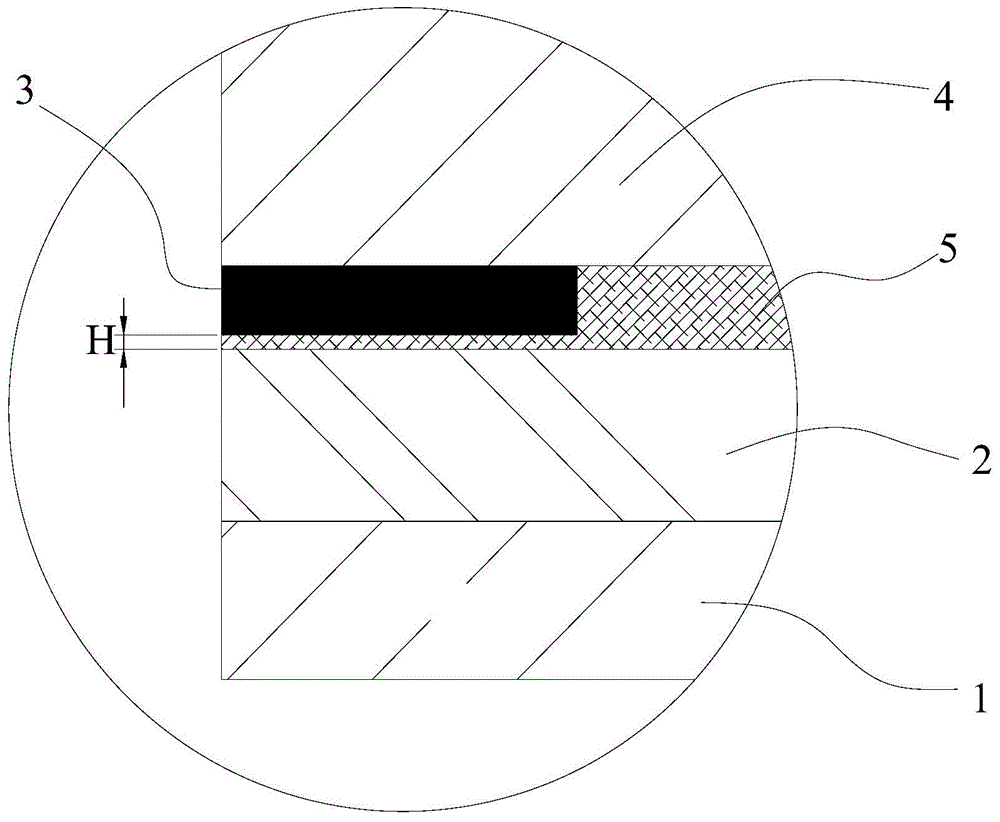

[0045] This example will specifically explain the touch screen of the portable electronic product disclosed in the present invention. Such as figure 2 As shown, the touch screen of a portable electronic product provided in this example includes a panel 4, an ink layer 3, a transparent adhesive layer 2, and a sensing layer 1 sequentially from top to bottom;

[0046] The ink layer 3 is arranged on the periphery of the lower surface of the panel 4, and the middle area of the lower surface of the panel 4 is a visible area not coated with ink;

[0047] Wherein, a layer of anti-foaming adhesive layer 5 is coated on the surface of the ink layer 3 and the visible area; the sensing layer 1 is pasted on the anti-foaming adhesive layer 5 through the transparent adhesive layer 2 .

[0048] Among them, the panel 4 can be two types of glass and film, and the film type specifically includes PC, PMMA or a composite board of PC and PMMA, etc., and its thickness generally varies slightly ac...

Embodiment 2

[0064] This example discloses a portable electronic product, which includes the touch screen described in Embodiment 1 above. Among them, portable electronic products may include mobile phones, tablet computers, e-books, PDAs, etc. In this example, only the touch screen on the portable electronic products is improved, and other components and their manufacturing methods on the electronic products are not improved. The touch screen has been specifically described in Embodiment 1, so it will not be repeated.

[0065] With the portable electronic product disclosed in this example, since the ink layer 3 in the touch screen and the surface of the visible area are coated with a layer of anti-foaming rubber layer 5, the above-mentioned anti-foaming rubber layer 5 can effectively eliminate the contact between the ink layer 3 and the visible area. The height difference between the glass panels provides a flat bonding surface for subsequent lamination with the transparent adhesive layer...

Embodiment 3

[0067] This example will specifically explain the preparation method of the touch screen of the portable electronic product disclosed in the present invention.

[0068] Such as Figure 5 Shown, described preparation method comprises the steps:

[0069] Step SA, preparing the sensing layer 1;

[0070] Step SB, setting a transparent adhesive layer 2 on the upper surface of the sensing layer 1;

[0071] Step SC, forming an ink layer 3 on the periphery of the lower surface of the panel 4, and forming a visible area not coated with ink in the middle area of the lower surface;

[0072] Step SD, coating a layer of anti-foaming adhesive layer 5 on the ink layer 3 and the visible area;

[0073] Step SE, pasting the sensing layer 1 compounded with the transparent adhesive layer 2 on the panel 4 with the anti-foam adhesive layer 5 .

[0074] Wherein the above-mentioned steps SA, SB prepare the sensing layer 1, and the process of setting the transparent adhesive layer 2 on the sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com