Gas-liquid mixing high-pressure washer

A high-pressure cleaner and gas-liquid mixing technology, applied to the cleaning method using liquid, the cleaning method using gas flow, cleaning methods and appliances, etc., can solve the dirty surface of power equipment, time-consuming and labor-intensive use, unsatisfactory use effect, etc. problem, to achieve the effect of novel and unique structure, good cleaning effect, simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

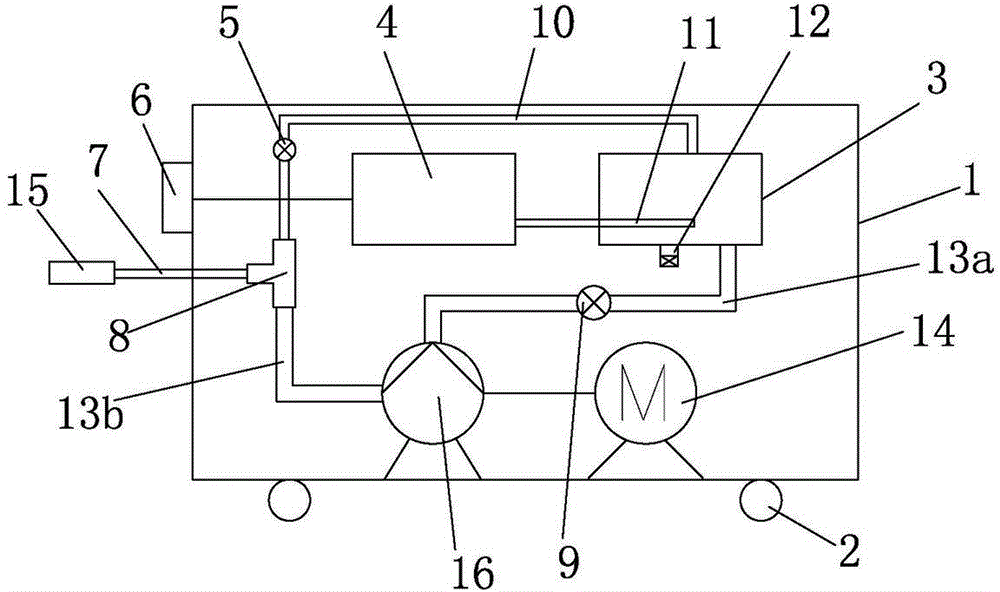

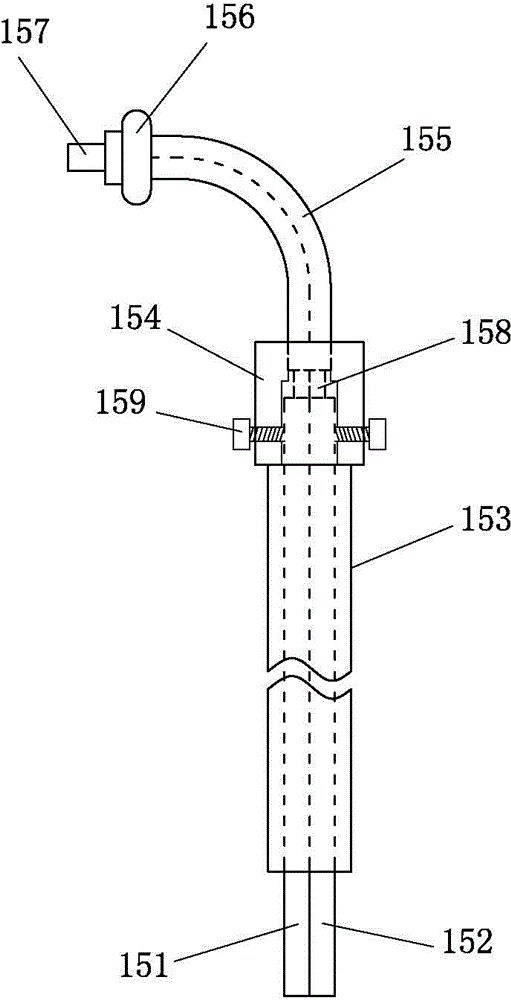

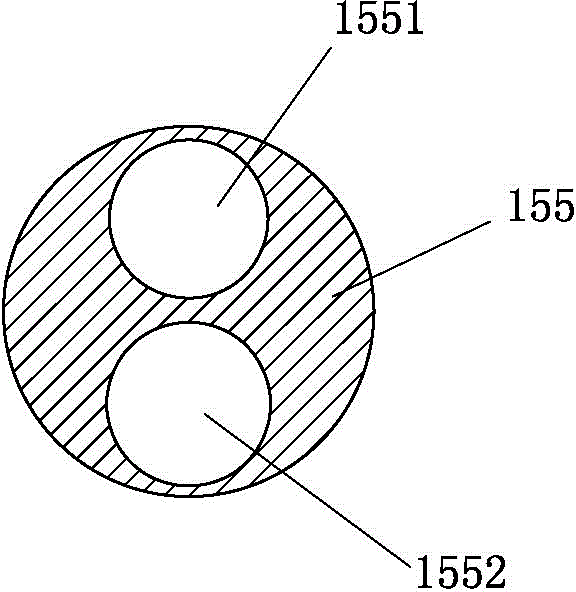

[0011] Depend on Figure 1-4 Provide, the present invention comprises cabinet, motor and centrifugal pump, and motor 14, centrifugal pump 16 and liquid storage tank 3 are housed respectively in the cabinet 1, and motor 14 links to each other with centrifugal pump 16, and the liquid outlet of liquid storage tank 3 passes through first The liquid outlet pipe 13a is connected with the liquid inlet of the centrifugal pump 16, and the liquid outlet of the centrifugal pump 16 is connected with the liquid inlet of the tee 8 through the second liquid outlet pipe 13b. Out of the injection pipe 7 of the chassis, another liquid outlet is connected to the liquid inlet of the liquid storage tank 3 through the return pipeline 10, and the first electromagnetic valve 9 is housed on the first liquid outlet pipeline 13a or the second liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com