Winding machine with protection door

A protective door and winding machine technology, which is applied in the direction of coil manufacturing and wing leaf layout, can solve the problems of large external space, inconvenient opening of the protective door, inconvenient product replacement, etc., and achieves a small footprint , opening and closing shortcuts, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

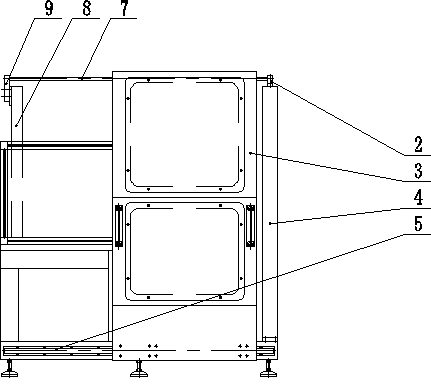

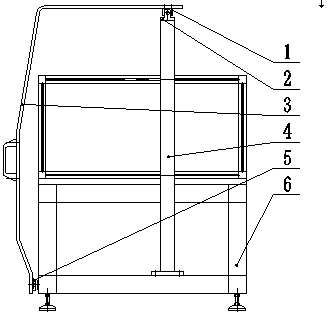

[0018] attached Figure 1-2 It is a winding machine with a protective door according to the present invention, which includes a protective door 3, a frame 6, and a sliding guide rod 7; the left and right sides of the rear end of the frame 6 are respectively vertically provided with first protective door pillars 4 and the second protective door pillar 8, the upper surface of the first protective door pillar 4 is provided with the first guide rod fixing seat 2, and the upper surface of the second protective door pillar 8 is provided with the second guide rod fixed Seat 9; the lower part of the front end of the frame 6 is provided with a horizontal protective door guide rail 5; the two ends of the sliding guide rod 7 are respectively arranged on the first guide rod holder 2 and the second guide rod holder 9; The protective door guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com