Fastened type chassis rail bracket

A fastening type, chassis technology, used in vehicle seats, movable seats, special positions of vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

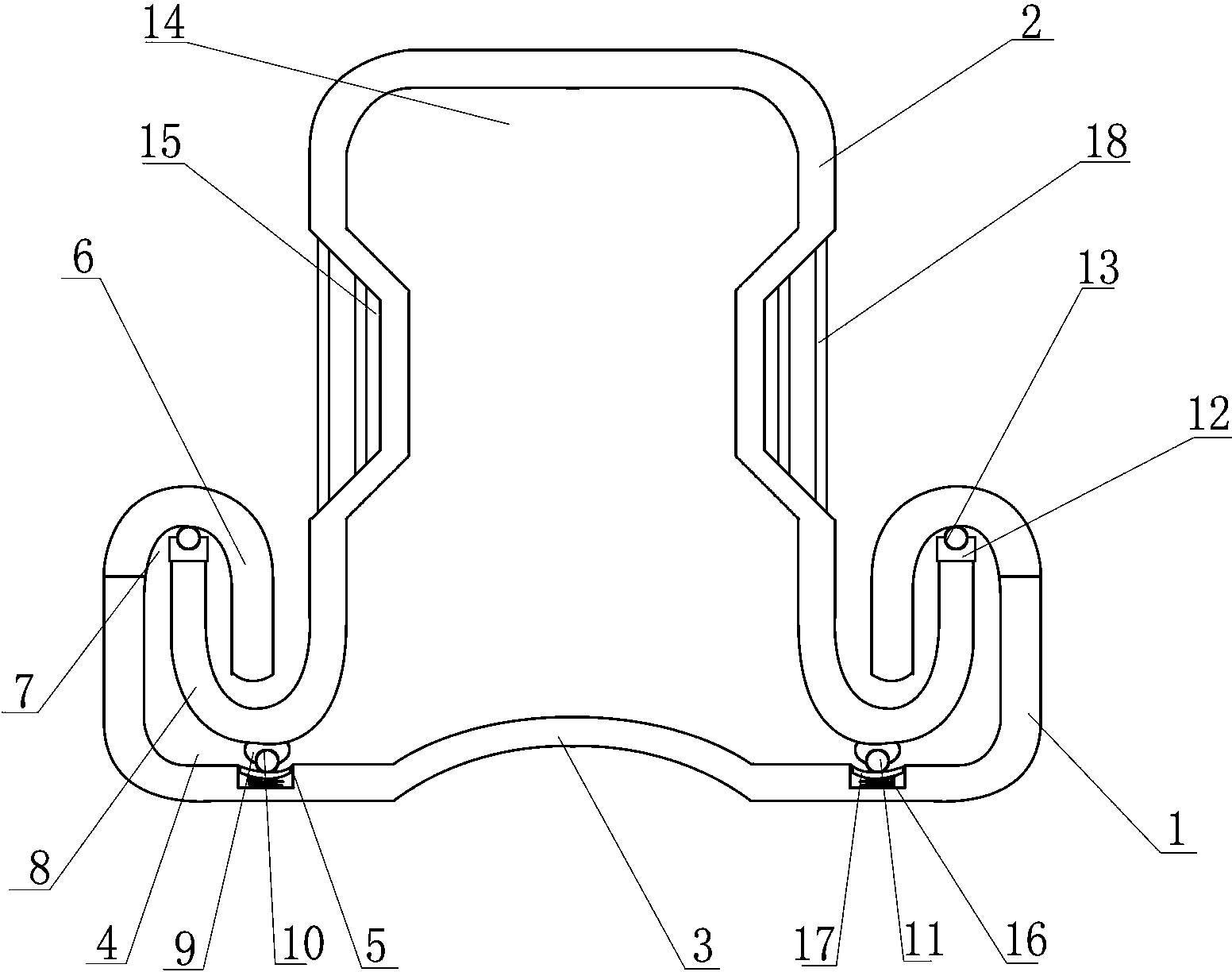

[0014] Specific embodiments of the present invention will be further described in detail below.

[0015] Such as figure 1 and figure 2 As shown, a fastening chassis guide rail bracket of the present invention includes a support frame 1 and a mobile frame 2 arranged on the upper part of the support frame 1. The support frame 1 is set in a rectangular shape with a hollow top, and the middle of the bottom of the support frame 1 is set upwards. There is an arc-shaped protrusion 3, a first groove 4 is formed between the protrusion 3 and the two sides of the support frame 1, a chute 5 is arranged in the first groove 4, and the mobile frame 2 is set in the shape of "a few", and the mobile frame 2. The barbs 8 at the two bottoms are arranged in the support frame 1, and the middle parts of both sides of the moving frame 2 are respectively provided with a trapezoidal second groove 15 inward.

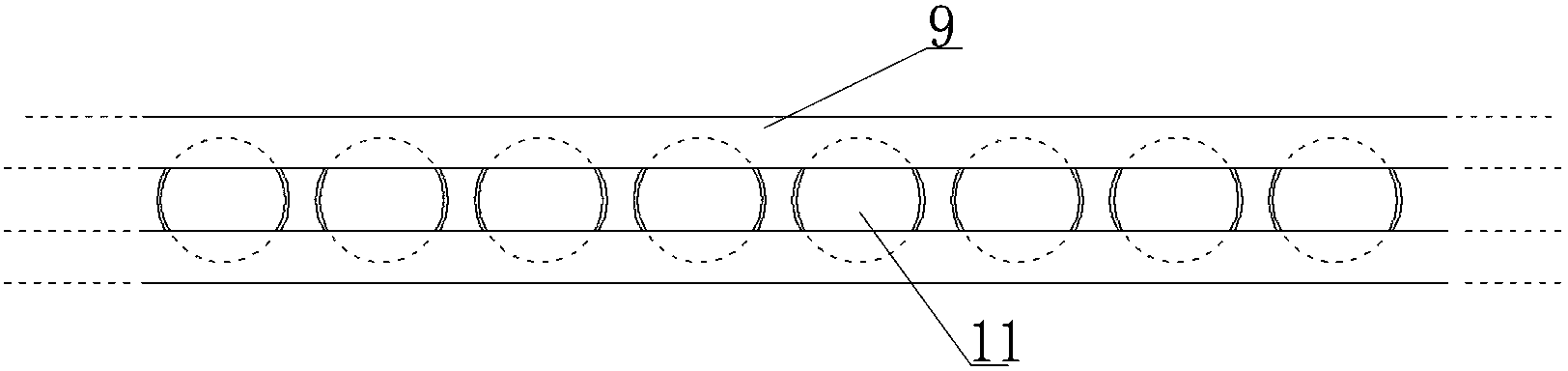

[0016] The chute 5 is provided with a row of elastic members 16, an arc-shaped slide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com