Triple co-generation system for heating cargo oil and ballast water and performing refrigeration by waste heat of oil tanker

A technology for ballasting water and cargo oil, applied in hull ventilation/heating/cooling, waterway transportation, climate sustainability, etc., can solve problems such as energy waste, achieve economical and practical effects, solve damage, and enhance heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings and embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

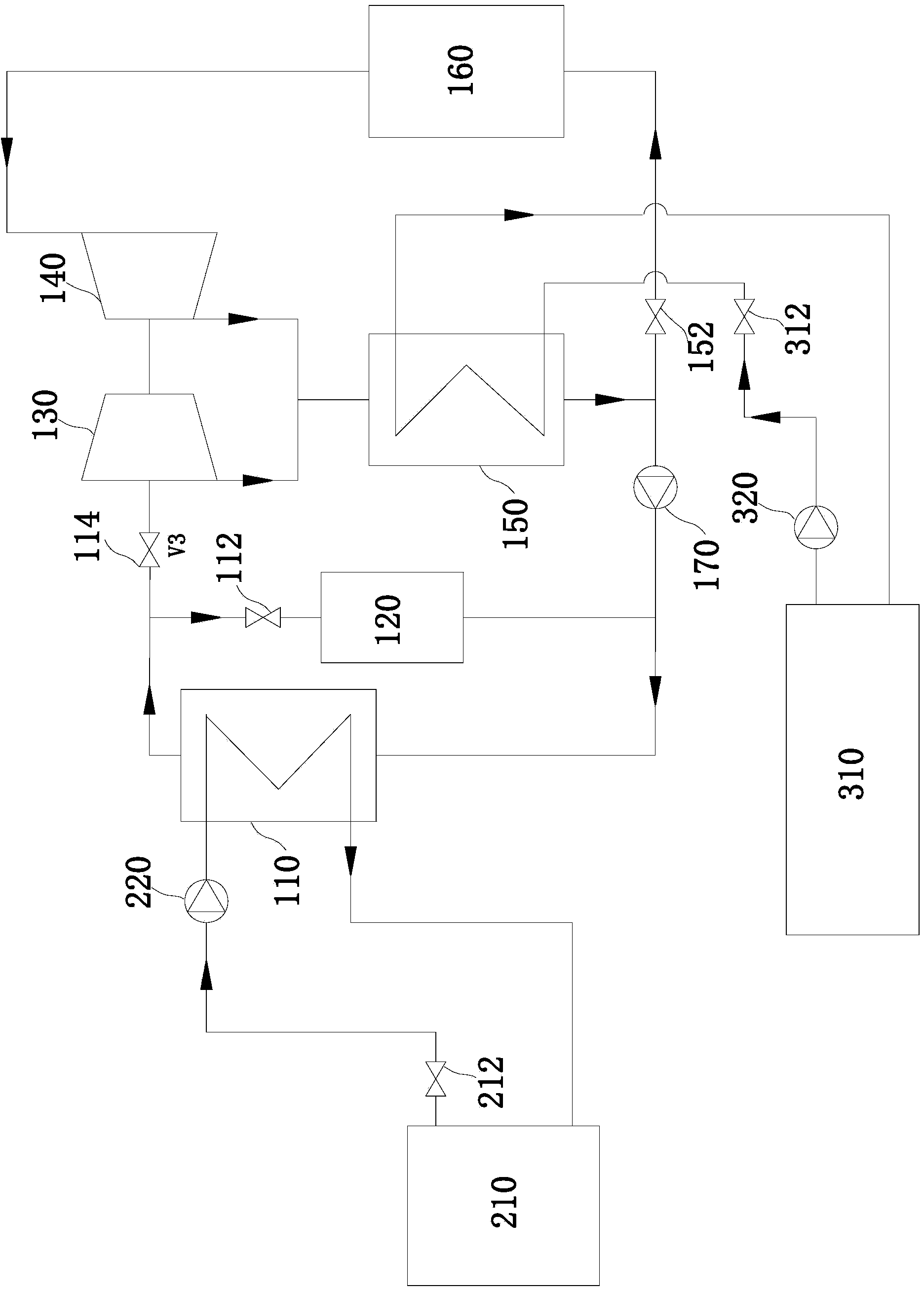

[0013] see figure 1 , figure 1 Embodiments of the tanker waste heat cargo oil heating, ballast water heating, and refrigeration triple supply system of the present invention are as follows.

[0014] The tanker waste heat cargo oil heating, ballast water heating, refrigeration triple supply system includes a generator 110 , a cargo oil heating coil 120 , a first valve 112 , a waste heat boiler 210 , a second valve 212 and a hot water pump 220 . Including generator 110, cargo oil heating coil 120, first valve 112, waste heat boiler 210, second valve 212, hot water pump 220, expander 130, compressor 140, condenser 150, evaporator 160, working medium pump 170 , the third valve 114 , the fourth va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com