Flexible external cloth winding mechanism

A flexible and cloth rolling roller technology, which is applied in the field of flexible cloth rolling mechanism outside the machine, can solve the problems of hard connection of the cloth rolling mechanism, fabric wrinkles, etc., and achieve the effect of solving wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

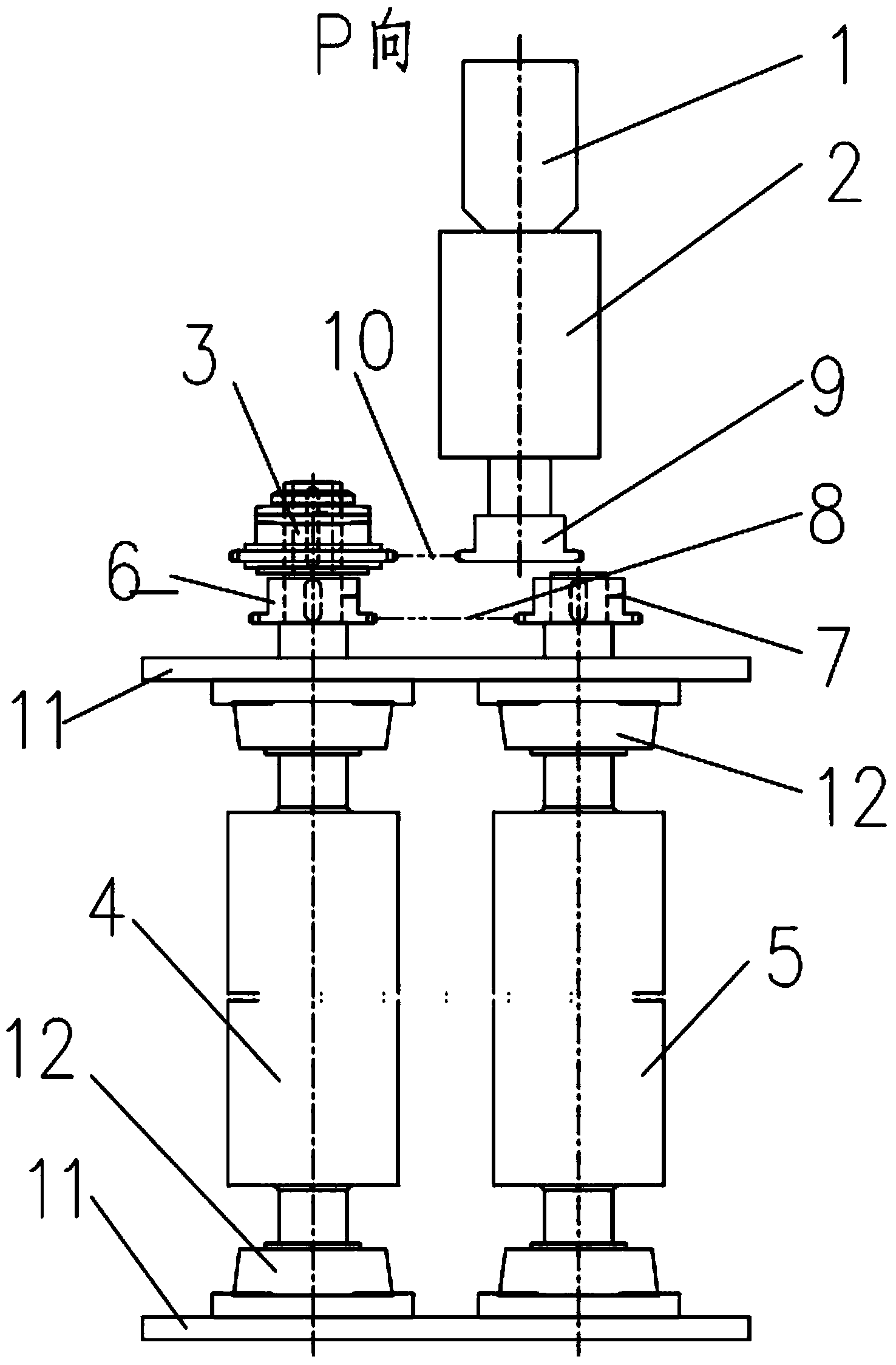

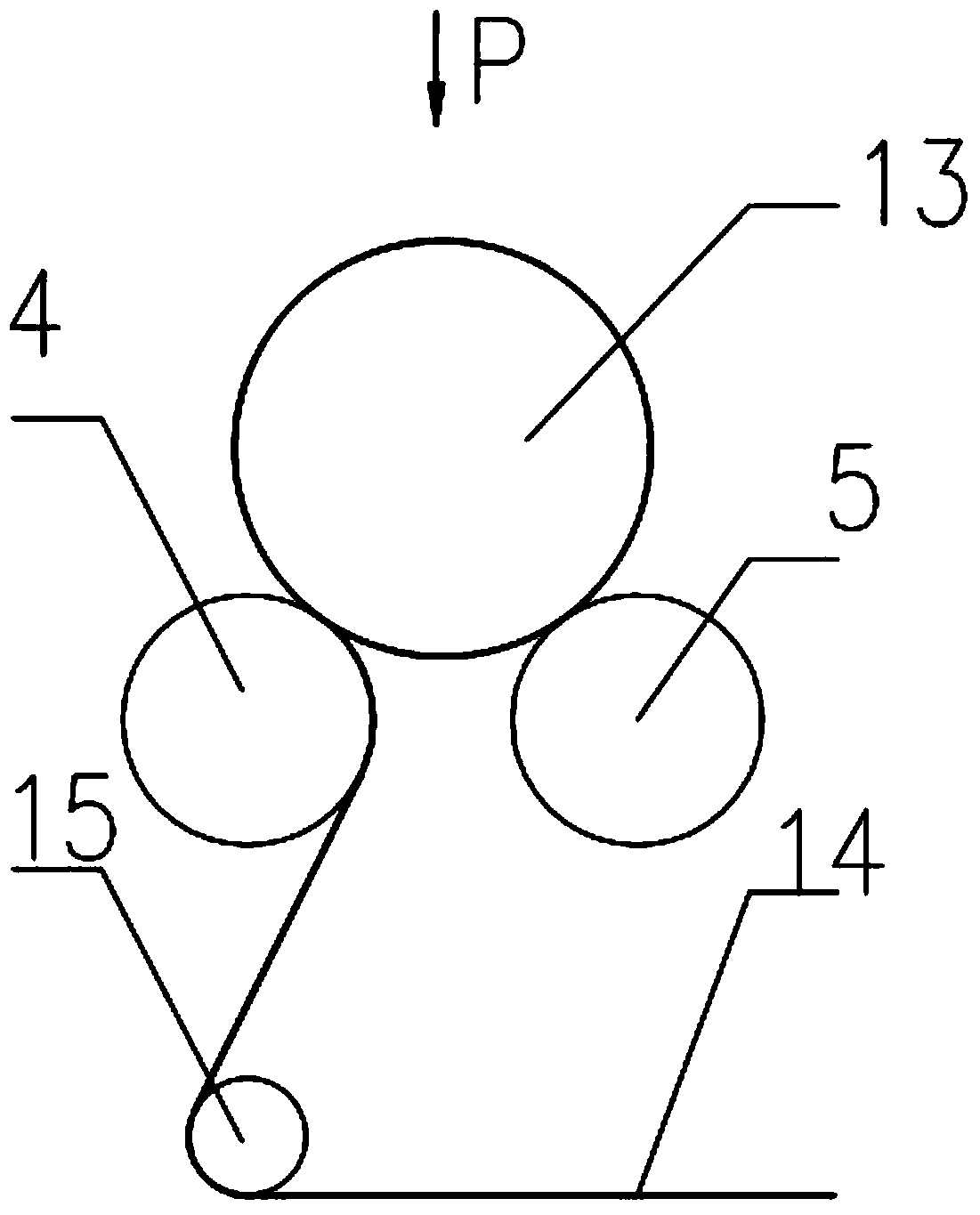

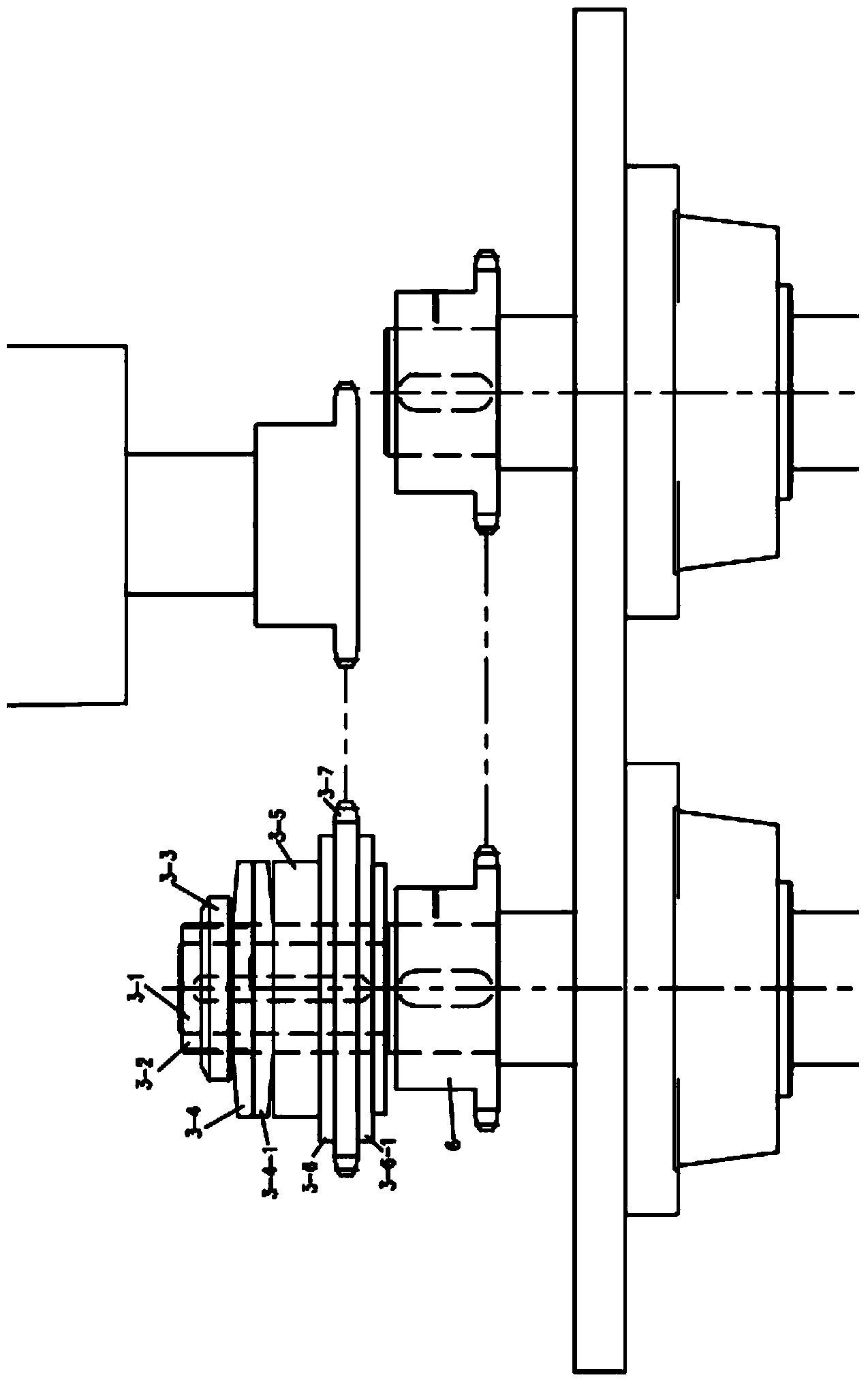

[0019] In the figure, the flexible cloth rolling mechanism outside the machine includes motor 1, reducer 2, friction coupling 3, driving roller 4 and driven roller 5, the output end of the motor is connected with the reducer, and the power output shaft of the reducer is connected The output shaft of the friction coupling is connected with the driving roller 4, wherein the driving roller 1 and the driven roller 2 are installed on the frame in parallel, and the driven roller and the driving roller are transmitted through a chain Power, the cloth rolling roller is located above the position between the driving roller 1 and the driven roller 2, and is used to take up the cloth 14 to form a cloth roll 13. The cloth rolling roller drives the cloth rolling roller to rotate through the rotation of the driving roller and the driven roller. Thereby the cloth is wound up, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com