Crane for electric tower

A technology for cranes and power towers, applied in the field of cranes for power towers, can solve the problems of occupying large site resources, high use costs, and high construction costs, and achieve the advantages of improving construction quality and efficiency, strong site adaptability, and reducing construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

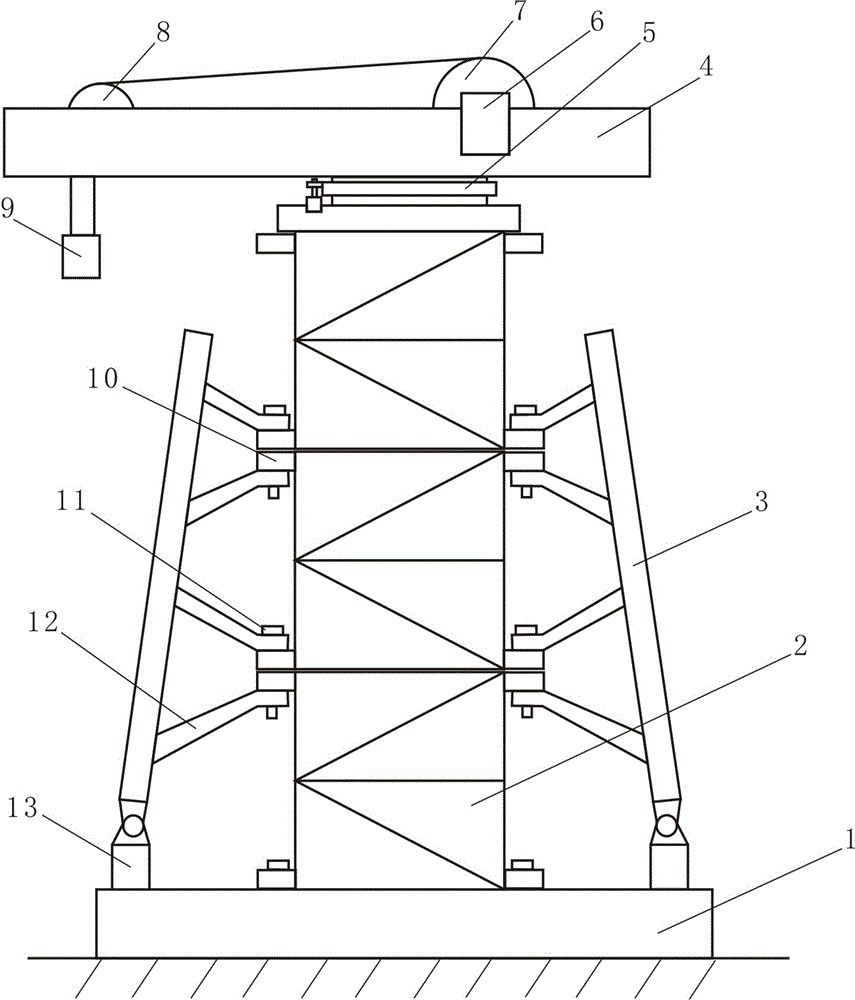

[0007] Now refer to the attached figure 1 , specifically described as follows in conjunction with the embodiment: a crane for a power tower includes a foundation foundation 1, a support column, a tower body standard section 2, a boom 4, a steering mechanism 5, a support wheel 8, a strand wheel 7, and a driving device 6. Suspension hook 9, backguy, reinforced beam and adjustment support 13. The support column is connected with the foundation 1 by bolts, and the support column is composed of at least two tower body standard sections, and the left and right sides of the upper and lower ends of the tower body standard section 2 are respectively provided with connecting ears 10, and connecting through holes are arranged in the connecting ears 10, The tower body standard sections 2 of two adjacent sections are fixedly connected through the connection through holes by bolts, and reinforced beams are respectively arranged on both sides of the supporting columns, and the reinforced bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com