Crane for electric power tower

A technology for power towers and cranes, applied in the field of power transmission and transformation, can solve the problems of occupying large site resources, high construction costs, and high work intensity, and achieve the effects of improving construction quality and efficiency, reducing construction costs, and maintaining a stable and lightweight structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

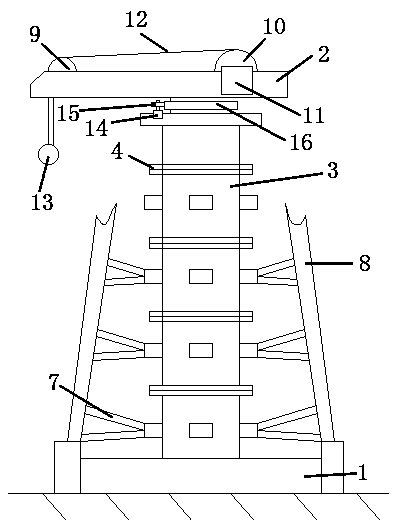

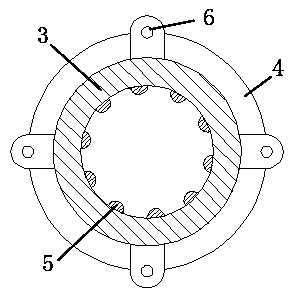

[0011] Such as figure 1 and 2 As shown, a crane for power poles and towers, the crane for power poles and towers is composed of a chassis plate 1, a support column, a lifting arm 2 and a strengthening beam, and the support column and the upper surface of the chassis plate 1 are connected by bolts. The supporting column is composed of at least two columns 3 and connected by bolts. The column 3 is a hollow cylindrical structure, wherein the two ends of the column are provided with connecting flanges 4, and the inner surface of the column is evenly distributed parallel to the axis of the column. of Reinforcement protrusion 5, the section of the reinforcement protrusion 5 is arc-shaped, and its outer surface has at least four hinged holes 6. The reinforcement beam is composed of at least two support arms 7, wherein one end of the support arm 7 is hinged and the included angle is The hinged end of the reinforced beam support arm 7 is hinged to the hinged hole 6 of the column body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com