Assembled simple house framework

A prefabricated and simple technology, applied in building construction, construction, etc., can solve the problems of labor and time-consuming, slow speed, low strength, etc., and achieve the effect of improving bearing capacity, reducing weight, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

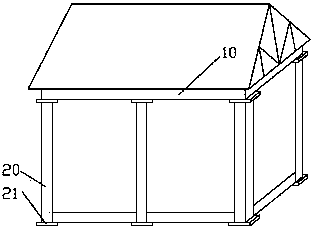

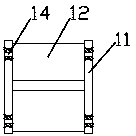

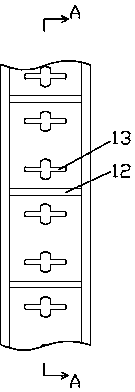

[0013] Figure 1 to Figure 4 It shows the assembled simple house structure provided by the present invention, including a bottom frame, a top frame, and at least four columns 20 connected between the bottom frame and the top frame; the bottom frame and the top frame are all connected by steel beams 10 , the steel beam 10 is H-shaped steel 11, the two surfaces of its web are evenly provided with reinforcing plates 12 at intervals, and the reinforcing plates 12 on the two surfaces of the web are interlaced; the webs between adjacent reinforcing plates 12 A cross-shaped hole 13 is provided; the ends of the two flange plates of the H-shaped steel 11 are provided with threaded holes 14, and the surfaces of the H-shaped steel 11 and the reinforcing plate 45 are provided with a bamboo fiber plastic layer 15; the column 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com