Down-sliding spherical rolling type point contact sliding window

A point-contact and rolling technology, applied in the field of sliding windows, can solve the problems of high maintenance cost and easy wear and tear of sliding windows, and achieve the effects of long working life, easy maintenance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

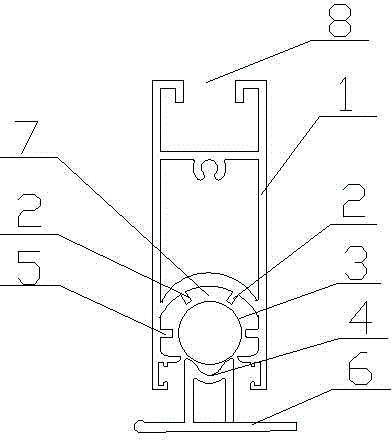

[0010] A sliding ball-shaped rolling point-contact sliding window includes a fixed glass frame 1, a rolling body 3, and a sliding base 6. Glass tank 8, fixed glass frame 1 is arranged on the upper end of sliding base 6 and forms a slideway space 7 with the arc-shaped slideway 4 on the sliding base 6, rolling body 3 is arranged in the slideway space 7, the fixing of rolling body 3 upper end Two guide ribs 2 are arranged on the glass frame 1, and the two guide ribs 2 are connected with the rolling body 3 and are in a point contact state with the rolling body 3. The fixed glass frame 2 on both sides of the rolling body 3 is symmetrically arranged with two Road reinforcement 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com