Improved connecting structure for front push rod and rear push rod of support

A connecting device and push rod technology, which is applied to mine roof supports, mining equipment, earth-moving drilling, etc., can solve the problems of unreliable connection, large force on the front and rear push rods, and difficult installation, so as to solve the inconvenient installation, disassembly and maintenance. , The effect of reducing installation space, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

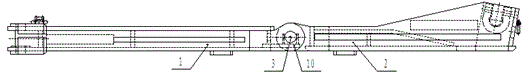

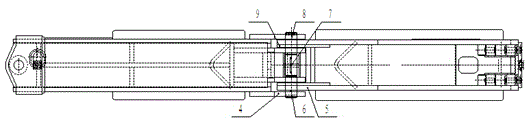

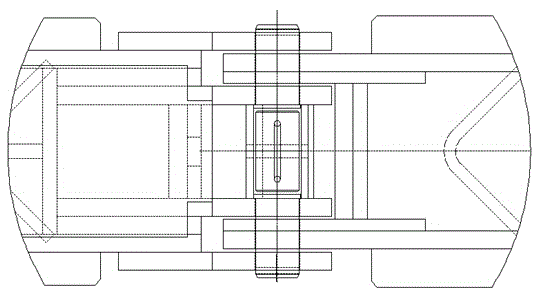

[0015] Such as Figure 1~4 As shown, an improved connection device for the front and rear push rods of a bracket, including a front push rod 1 and a rear push rod 2, the right end of the front push rod 1 is provided with double ears 3 vertically arranged up and down, and the left end of the rear push rod 2 is provided with The double ears 4 arranged vertically up and down, the front push rod 1 and the rear push rod 2 are connected vertically through the through holes on the double double ears 4 and double ears 5 through the pin shaft 3, and the double ears 5 are embedded in the double double ears 4 Among them, the pin shaft 3 adopts three-stage detachable connection, that is, the first pin shaft 6, the stop pin 7 and the second pin shaft 8 in sequence, the stop pin 7 is fixed in the groove of the support 10, and the The first pin shaft 6 and the second pin shaft 8 are placed in the holes of the double ears 4 and the double ears 5, and the segmented pin shaft 3 is installed ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com