Mechanism special for acting counter balance force of ultra-large torque standard device on ground

A torque standard device and a technology for balancing the force arm, which are used in measuring devices, force/torque/work measuring instrument calibration/testing, measuring fluid pressure, etc. Effect of large balance torque

Inactive Publication Date: 2015-02-18

SHANGHAI MARINE EQUIP RES INST

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for super-large deadweight torque standard machines, this structure cannot be realized

Because the existing motor cannot provide enough output torque to balance the super large standard torque generated by the standard arm weight

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

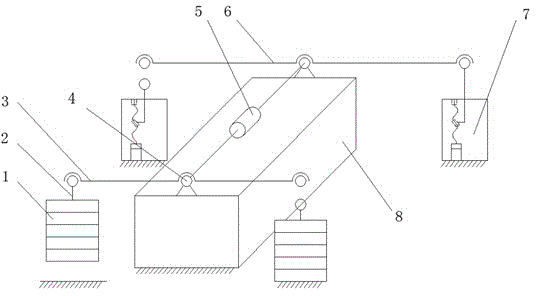

[0016] Such as figure 1 As shown, a mechanism dedicated to the super large torque standard device to balance the reaction force acting on the ground, including a standard weight 1, a weight hook 2, a standard force arm 3, a support component 4, a balance force arm 6, a leveling mechanism 7 and a base seat 8.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a mechanism special for acting counter balance force of an ultra-large torque standard device on the ground. The mechanism comprises a standard force arm, supporting components, a balance force arm and a base, a tested torque sensor, two sets of standard weights and two sets of leveling mechanisms are arranged between the standard force arm and the balance force arm, and the standard weights and the leveling mechanisms are used for carrying out clockwise and anticlockwise testing on the tested torque sensor. In the testing process, one standard weight and one leveling mechanism are distributed on every two opposite angles of the standard force arm and the balance force arm, gear motors are arranged in the leveling mechanisms, and drive the leveling mechanisms, and the balance force arm is made to rotate around the corresponding supporting component and used for balancing the standard force arm. According to the mechanism, large enough balance torque can be provided for standard torque, and meanwhile it can be ensured that deformation, caused by twisting force, of a machine tool body is avoided.

Description

technical field [0001] The invention relates to a measurement detection, torque detection calibration, and torque testing device, in particular to a mechanism specially used for a super large torque standard device to balance the reaction force acting on the ground. Background technique [0002] Deadweight torque standard device is a high-precision torque measurement equipment. This equipment is composed of a standard force arm, a standard weight, a force arm supporting part, a machine tool body and a balance part. Traditional balancing components are fixed on the machine tool and driven by a motor. However, this structure cannot be realized for the ultra-large deadweight torque standard machine. Because the existing motor cannot provide a large enough output torque to balance the super large standard torque produced by the standard force arm weight. In order to solve this problem, it is necessary to adopt a design technology that balances the reaction force acting on the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01L25/00G01L27/00

Inventor 李涛吉鸿磊童小川倪昔东王跃武王佩君

Owner SHANGHAI MARINE EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com