Brake device

A braking device, braking surface technology, applied in the direction of brake type, brake actuator, mechanically driven drum brake, etc., can solve problems such as inability to exceed, the inability of the brake cam to rotate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

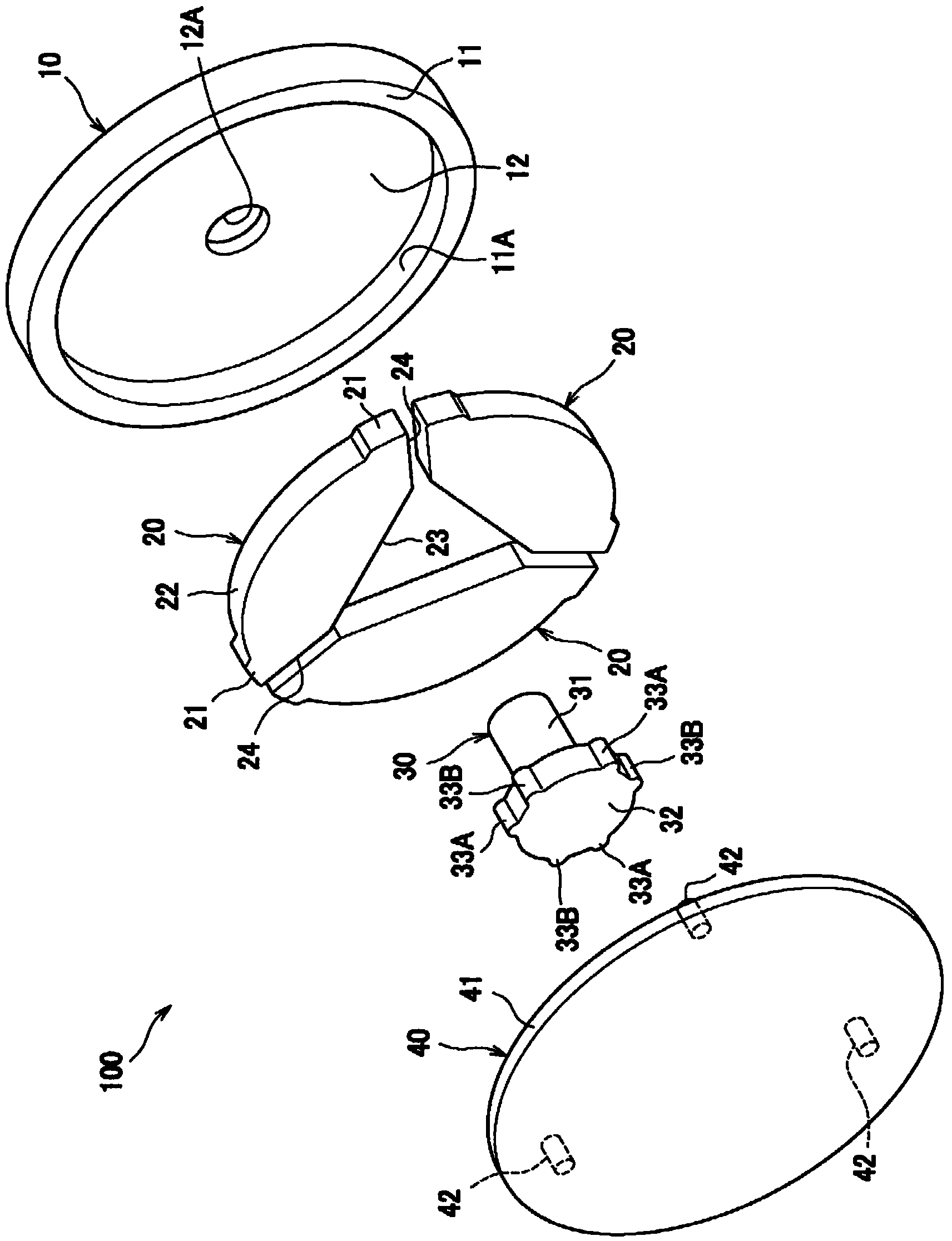

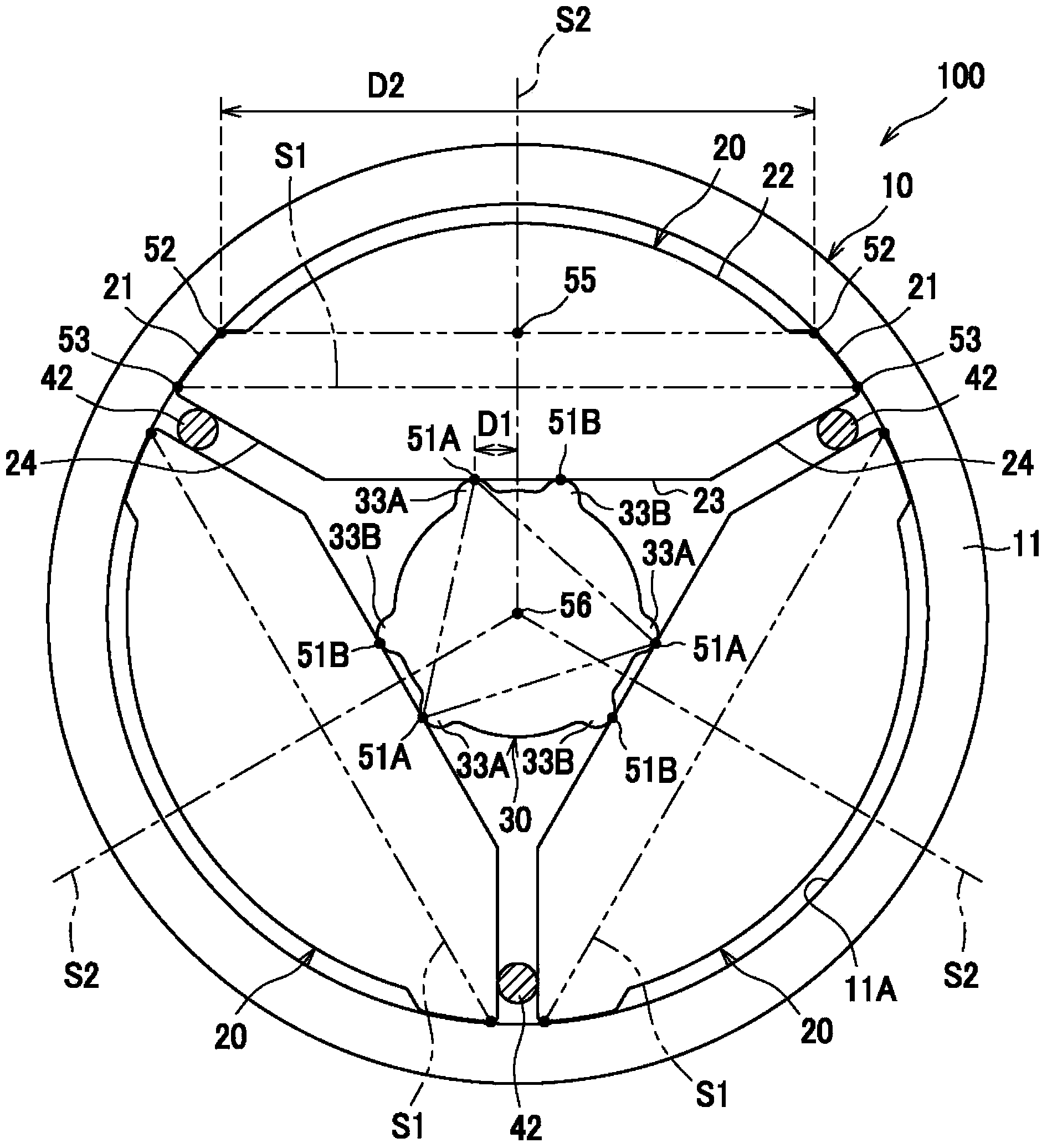

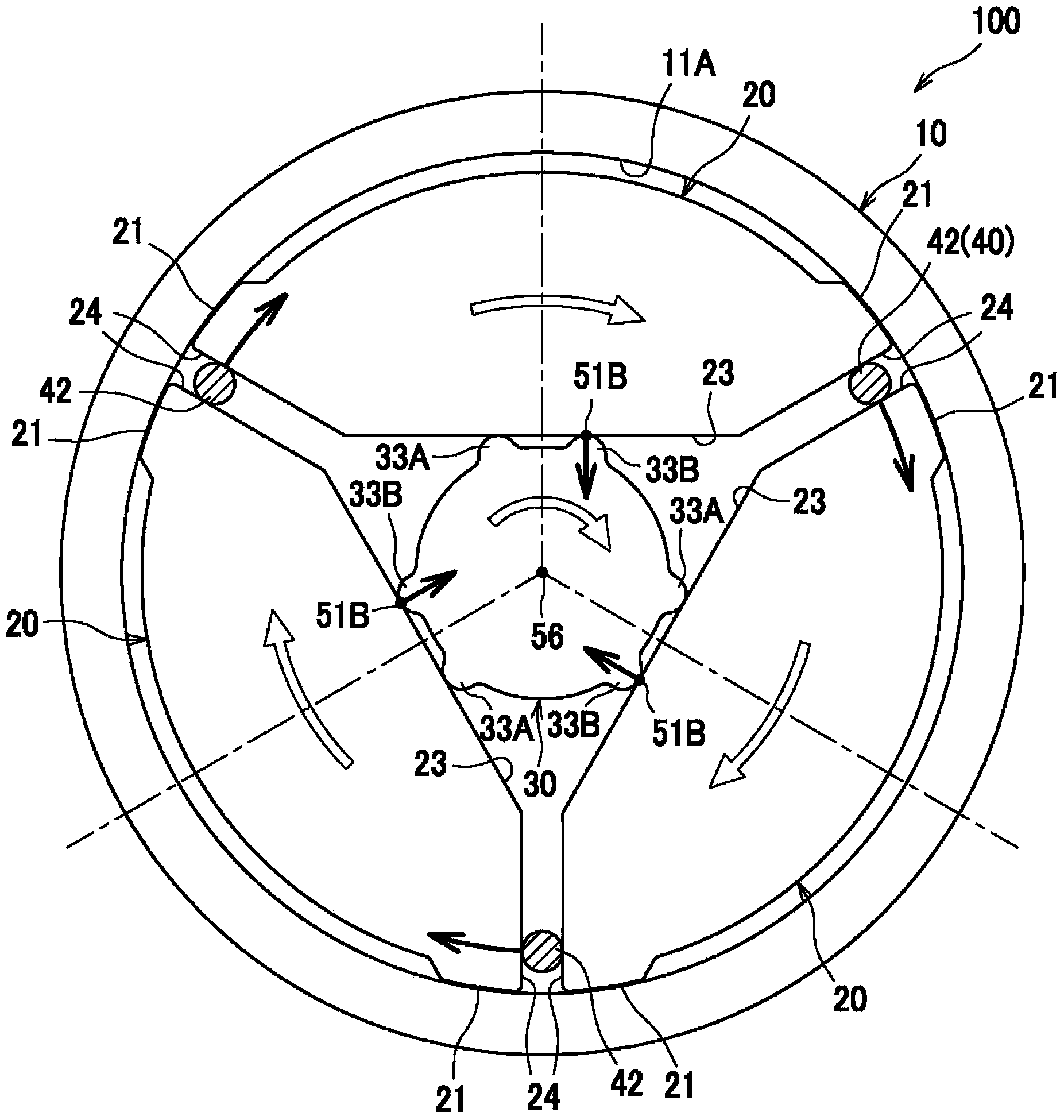

[0032] Hereinafter, specific embodiments of the present invention will be described in detail by referring to the drawings where appropriate. Such as figure 1 As shown, a brake device 100 according to an embodiment includes an outer ring 10 , a brake cam 20 , an output-side rotating member 30 and an input-side rotating member 40 .

[0033] The outer ring 10 includes an annular portion 11 having a certain thickness and a side wall 12 provided on one side of the annular portion 11 . The annular portion 11 has a cylindrical inner peripheral surface 11A (having a circular cross section). The side wall 12 has a through hole 12A formed therein at a position corresponding to the central axis of the inner peripheral surface 11A.

[0034] The brake cam 20 is a member for generating a braking force on its surface in contact with the outer ring 10 . Three detent cams 20 are arranged equidistantly on the inner side of the outer ring 10 in the circumferential direction. Each braking ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com