Hydraulic adjustable excavation harvesting mechanism for potato harvester

A harvester and potato technology, applied in the field of agriculture, can solve the problems of incomplete digging of potatoes, waste of crops, damage to potatoes, etc., and achieve the effects of increasing temporary storage capacity, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

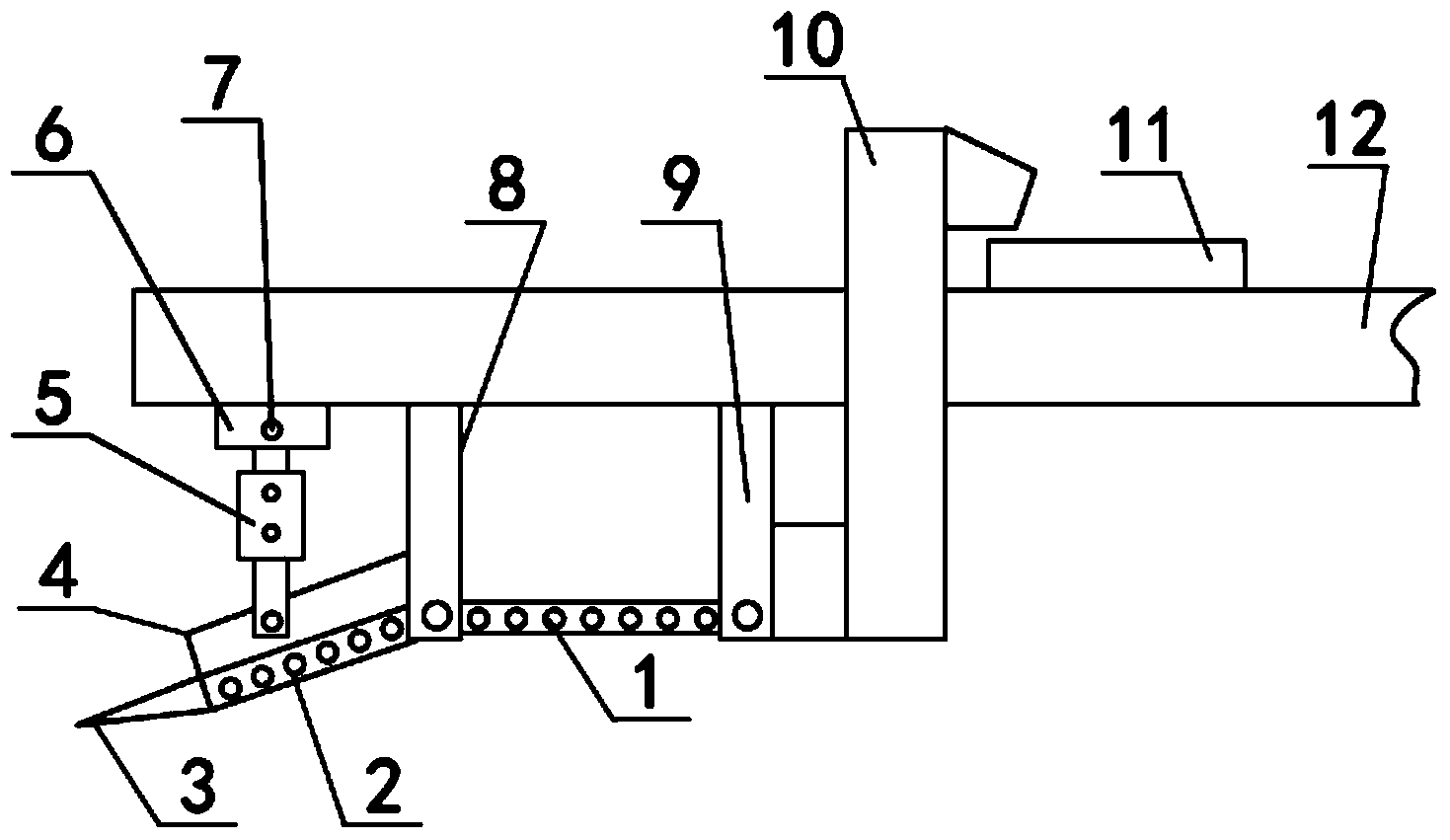

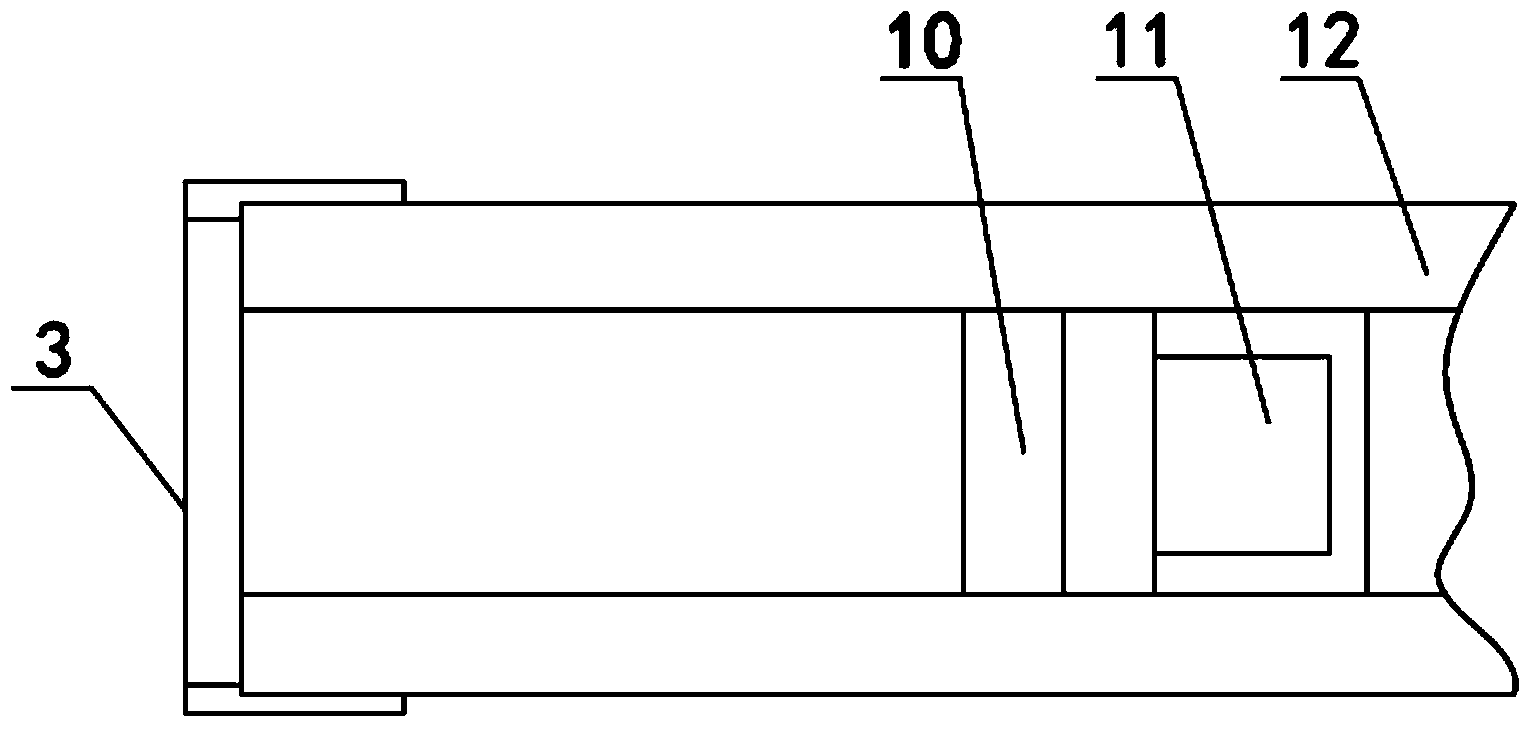

[0018] like figure 1 , figure 2 As shown, the hydraulically adjustable digging and harvesting mechanism used by the potato harvester includes a digging shovel 3, a roller conveyor and a main frame 12, and a first mounting bracket 8 and a first mounting bracket 8 are vertically arranged at the bottom of the main frame 12 from left to right The second mounting bracket 9, the first mounting bracket 8 and the second mounting bracket 9 are arranged in parallel, and the third mounting bracket 4 is hinged on the left side of the first mounting bracket 8; The first roller conveyor 2 and the second roller conveyor 1 are composed, the first roller conveyor 2 is installed on the third mounting bracket 4, and the second roller conveyor 1 is installed on the first mounting bracket 8 and the second Between the mounting brackets 9, the excavating shovel 3 is installed on the third mounting bracket 4 corresponding to the inlet end of the first roller conveyor 2, and the bottom of the main f...

Embodiment 2

[0022] This embodiment is changed on the basis of the first embodiment, the length of the second roller conveyor 1 is changed to 70 mm; the adjustable angle range of the excavating shovel 3 into the soil is 50 degrees. Others are the same as embodiment one.

Embodiment 3

[0024] This embodiment is changed on the basis of the first embodiment, the length of the second roller conveyor 1 is changed to 60mm; the adjustable angle range of the excavating shovel 3 into the soil is 40 degrees. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com